Preparation method of salt-erosion-resistant marine concrete

A technology for marine concrete and preparation steps, which is applied in the field of preparation of salt-resistant marine concrete, can solve problems such as threatening service life, loss of durability, and damage to concrete structures, and achieve increased penetration resistance, improved interface structure and adhesion The effect of binding force and improving the performance of anti-chloride ion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

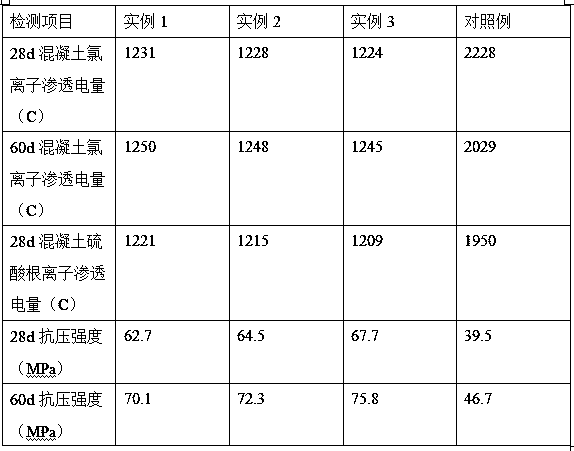

Examples

Embodiment Construction

[0021] Mix rice husk and biogas slurry at a mass ratio of 1:5 and put them into stainless steel trays, and put the stainless steel trays in a greenhouse with a temperature of 30-40°C and a relative air humidity of 70-80%, and let it stand for 3-40°C. After standing for 5 days, filter and separate to obtain the filter residue, which is the pretreated rice husk; the pretreated rice husk and the concentration of 1mol / L citric acid solution are mixed in a mass ratio of 1:10 and put into an ultrasonic oscillator to 200-300W power ultrasonic vibration impregnation for 1-2 hours, after the impregnation, filter and separate to obtain the impregnated filter residue; then pour the impregnated filter residue into the aluminum chloride solution with a concentration of 0.5mol / L according to the mass ratio of 1:5, and stir for 20 After ~30 minutes, filter and separate to obtain the reaction filter residue, continue to slowly add the reaction filter residue to the sodium hydroxide solution wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com