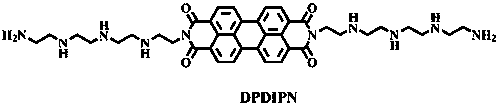

Method for preparing polyamine branched chain containing perylene bisimide cathode interface layer

A technology containing polyamine perylene imide and cathode interface layer, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc. It can solve the problems of sensitive layer thickness, poor morphology of the upper active layer, and sensitive interface layer thickness, so as to solve the problem of interface layer thickness sensitivity, improve the morphology, and reduce the interface barrier.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

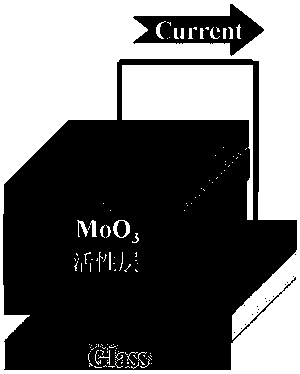

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

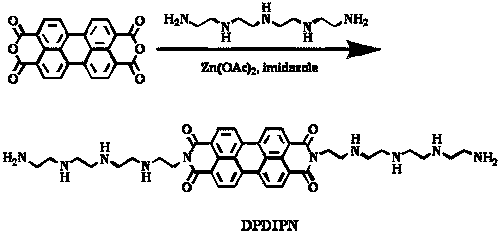

[0017] The reaction equation of the present invention is attached figure 2 , the specific reaction steps are as follows:

[0018] (1) Synthesis steps of polyamine-branched peryleneimide derivative cathode interface layer:

[0019] Under nitrogen protection, add 2.50 g of 3,4,9,10-perylenetetracarboxylic anhydride, 127 mg of catalytic zinc acetate, 10 g of imidazole and 2.89 g of tetraethylenepentamine to a 250 mL dry nitrogen bottle, The reaction solution was stirred and refluxed overnight at 135°C. After the reaction, cool to room temperature, pour into a large amount of acetone and stir for three hours, filter to remove imidazole and unreacted tetraethylenepentamine, wash the filter residue with acetone several times, collect the filter residue, and dissolve the filter residue with methanol. The obtained crude product was passed through the column with neutral al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com