Rubber composition and processing method, and high-strength products using the same and production method

A rubber composition and high-strength technology, applied in the rubber field, can solve the problems affecting processing efficiency and product performance, difficult free radical reaction, large steric hindrance, etc., achieve good electrical insulation performance and mechanical strength, wide application, insulation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

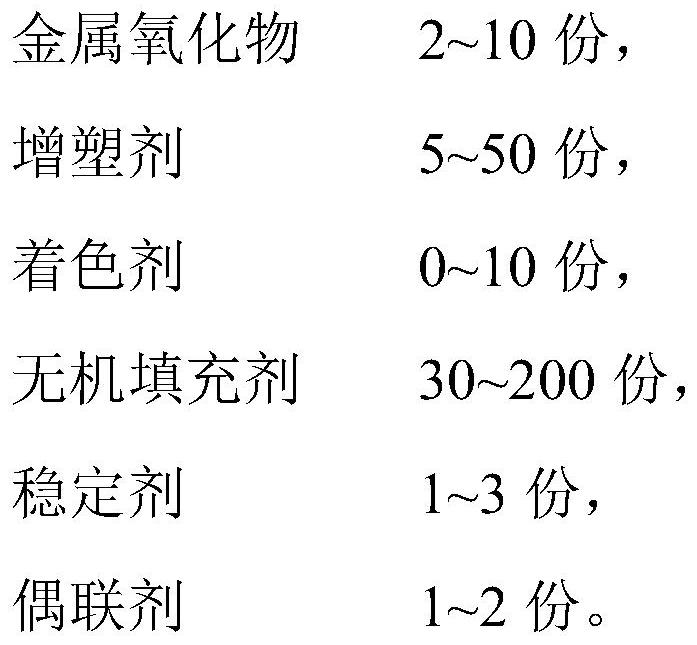

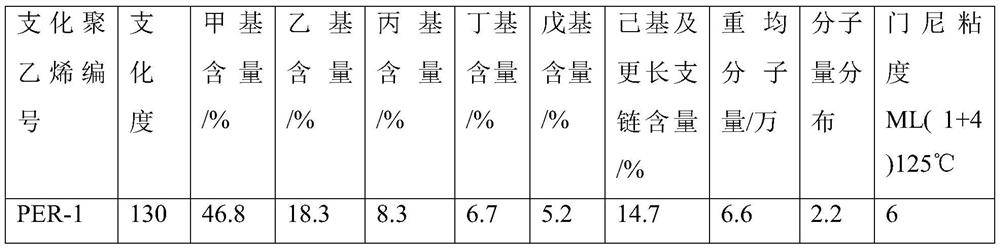

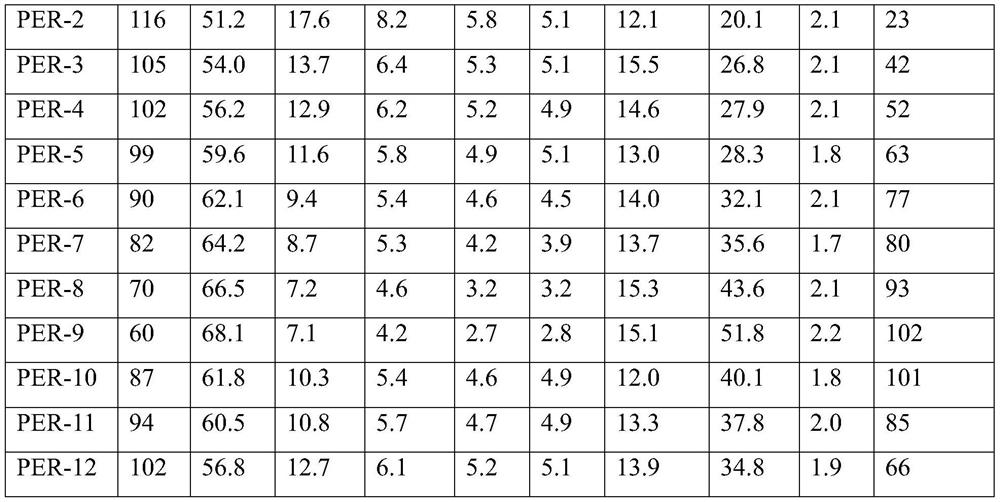

Method used

Image

Examples

Embodiment 1

[0114] The number of branched polyethylene used in this example is PER-9.

[0115] The processing method is as follows:

[0116] (1) Rubber mixing: set the temperature of the internal mixer to 100°C, and the rotor speed to 50 rpm, add 90 parts of binary ethylene propylene rubber and 10 parts of branched polyethylene for pre-compression mixing for 90 seconds; add 5 parts of oxidized Zinc, 1 part of stearic acid, 2 parts of anti-aging agent RD, knead for 30 seconds; then add 100 parts of talcum powder, 20 parts of paraffin oil SUNPAR2280 to the rubber compound, knead for 3 minutes; finally add 3 parts of cross-linking agent peroxide Dicumyl (DCP), 1 part of triallyl isocyanurate (TAIC), a co-crosslinking agent, mixed for 2 minutes and then discharged. Thinly pass the mixed rubber on an open mill with a roller temperature of 60°C to obtain a thin sheet with a thickness of about 2.5mm, and park it for 20 hours;

[0117] (2) Vulcanization: Vulcanize at 160°C and 16MPa pressure fo...

Embodiment 2

[0119] The number of branched polyethylene used in this example is PER-2.

[0120] The processing method is as follows:

[0121] (1) Rubber mixing: set the temperature of the internal mixer to 60°C, and the rotor speed to 50 rpm, add 70 parts of binary ethylene propylene rubber and 30 parts of branched polyethylene for pre-compression mixing for 90 seconds; add 5 parts of oxidized Zinc, 1 part of stearic acid, 2 parts of antioxidant RD, knead for 30 seconds; then add 100 parts of talc powder, 10 parts of paraffin oil SUNPAR2280 to the rubber compound, knead for 3 minutes; finally add 3 parts of crosslinking agent DCP, 0.3 parts of sulfur, after mixing for 2 minutes, remove the glue. Thinly pass the mixed rubber on an open mill with a roller temperature of 40°C to obtain a thin sheet with a thickness of about 2.5mm, and park it for 20 hours.

[0122] (2) Vulcanization: Vulcanize at 160°C and 16MPa pressure for 30 minutes, and conduct various tests after parking for 16 hours. ...

Embodiment 3

[0124] The number of branched polyethylene used in this example is PER-4.

[0125] The processing method is as follows:

[0126] (1) Rubber mixing: set the temperature of the internal mixer to 80°C, and the rotor speed to 50 rpm, add 50 parts of binary ethylene propylene rubber and 50 parts of branched polyethylene for pre-compression mixing for 90 seconds; add 5 parts of oxidized Zinc, 1 part of stearic acid, 2 parts of anti-aging agent RD, knead for 30 seconds; then add 100 parts of talc powder, 20 parts of paraffin oil SUNPAR2280 to the rubber compound, knead for 3 minutes; finally add 3 parts of crosslinking agent DCP, 1 part of auxiliary cross-linking agent TAIC, after mixing for 2 minutes, remove the glue. Thinly pass the mixed rubber on an open mill with a roller temperature of 60°C to obtain a thin sheet with a thickness of about 2.5mm, and park it for 20 hours.

[0127] (2) Vulcanization: Vulcanize at 160°C and 16MPa pressure for 30 minutes, and conduct various test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com