Method for extracting chloroplasts from Chlamydomonas reinhardtii

An extraction method and chloroplast technology are applied in the field of Chlamydomonas reinhardtii chloroplast extraction, which can solve the problems of distorted chloroplast membrane structure, time-consuming and labor-intensive, unfavorable repeated chloroplast extraction, etc., and achieve the effect of maintaining integrity and ensuring sufficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 algae culture

[0040] Chlamydomonas reinhardtii can be either the biomass obtained under eutrophic conditions or the biomass obtained under nutrient stress conditions.

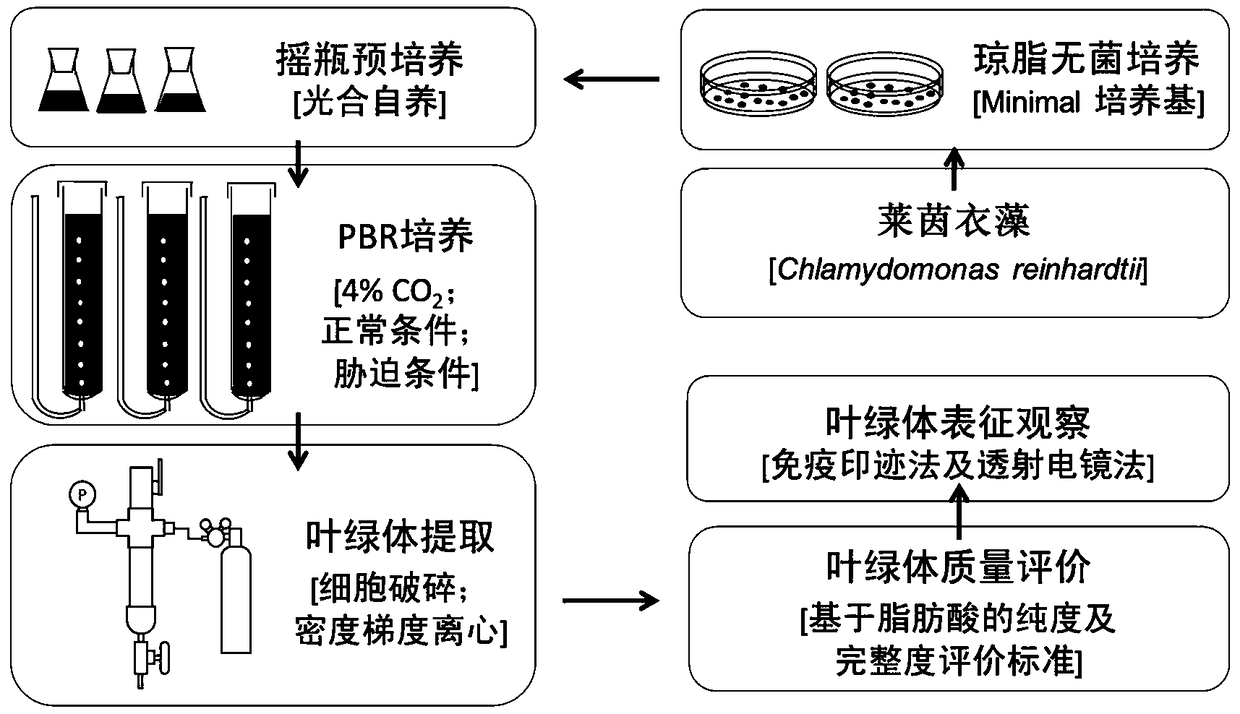

[0041] Algal cells were first grown on solidified agar Minimal medium, and then the monoclonal algae spots were transferred to liquid Minimal medium for photoautotrophy, and the photoperiod was set to 12h light / 12h dark (synchronization). The algal liquid was cultured synchronously for 4 days and then transferred to the photobioreactor (PBR) to continue the culture ( figure 1 ), cultured under continuous light for the first 48 h, and then cultured with a synchronous photoperiod of 12 h light / 12 h dark for the next 52 h, with a light intensity of 50 μmol m -2 the s -1 , when the algae cell density increased to 1×10 7 ml -1 When , some algal cells were harvested, and the centrifugation conditions were 3000g, 5min, 4°C. These algal cells were the biomass of eutrophic culture. A part of t...

Embodiment 2

[0049] The extraction of embodiment 2 chloroplasts

[0050] Wash the algae cells containing 10mg chlorophyll twice with 50ml 50mM Hepes-KOH pH 7.5 under centrifugation conditions of 3000g, 5min, 4°C, discard the supernatant and add 4ml 50mM Hepes-KOH pH 7.5.

[0051] Add 20ml of chloroplast separation buffer to resuspend the cells, and the chlorophyll concentration of the obtained algae cell concentrate is 0.5mgml -1 , pass the above-mentioned algae cell concentrate through a stainless steel needle disruptor (such as figure 1 The stainless steel needle crusher with equivalent crushing effect shown above) is used for crushing. The crusher includes a pipe body with upper and lower ends open. The upper opening end of the pipe body is used as a feeding port. A needle is connected, the lower opening end of the tube is airtightly connected with the needle, the upper part of the tube is provided with a gas interface, and the gas interface is connected with an inert atmosphere gas so...

Embodiment 3

[0057] The quality evaluation of embodiment 3 chloroplasts

[0058] Chloroplast Yield Parameters

[0059] Yield of chloroplast = total chlorophyll content of chloroplasts / total chlorophyll content of algal cells × 100%, and the algal cells used to extract chloroplasts shall be those containing 10 mg of chlorophyll.

[0060] Yield of chloroplasts under normal culture conditions

[0061] The chloroplast yield under normal conditions obtained based on different crushing pressures and centrifugal forces in Example 2 is 13-30%, as shown in Table 1.

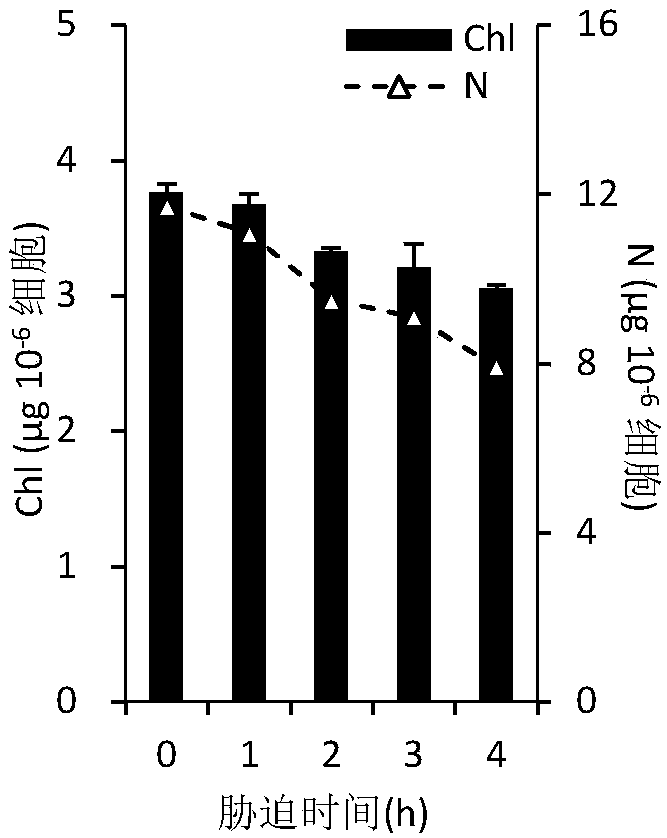

[0062] Yield of chloroplasts under nutrient stress conditions

[0063] The nitrogen stress chloroplast productive rate obtained based on different crushing pressures and centrifugal force in embodiment 2 is 0.5~3%, as shown in table 1, the significant decline of its productive rate (as Figure 5 (shown) shows that the difficulty of extracting chloroplasts under stress increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com