Method for recovering and using waste fermentation broth of paenibacillus polymyxa

A technology of polymyxa spore and Bacillus, which is applied to the recycling and utilization of Paenibacillus polymyxa fermentation waste liquid, bacillus fermentation synergist and fermentation synergistic field, can solve the problem of unfavorable energy saving, emission reduction and waste of supernatant liquid components , environmental pollution and other issues, to achieve the effect of increasing spore formation rate, reducing dosage and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] After the fermentation and cultivation of Paenibacillus polymyxa, the bacteria sludge with high specific gravity is collected by centrifugation, spray-dried to prepare Paenibacillus polymyxa bacteria powder, and the supernatant of the centrifuged fermentation liquid is recycled according to the following steps:

[0024] (1) Add 0.05% chitosan by weight to the Paenibacillus polymyxa fermentation waste liquid obtained by centrifugation, stir again after 10 minutes and get the supernatant;

[0025] (2) Add 0.001% amylase by weight to the supernatant, and perform enzymatic hydrolysis for 60 minutes;

[0026] (3) Add the supernatant after enzymolysis to the Bacillus fermentation medium after passing through a strongly acidic styrene-based cation exchange column.

Embodiment 2

[0028] (1) Add 0.1% chitosan to the Paenibacillus polymyxa fermentation waste liquid obtained by centrifugation, and centrifuge again after stirring for 1 minute to get the supernatant;

[0029] (2) Add 0.005% amylase to the supernatant, and perform enzymatic hydrolysis for 15 minutes;

[0030] (3) Add the supernatant after enzymolysis to the Bacillus fermentation medium after passing through a strongly acidic styrene-based cation exchange column.

Embodiment 3

[0032] (1) Add 0.08% chitosan to the Paenibacillus polymyxa fermentation waste liquid obtained by centrifugation, stir for 5 minutes and then centrifuge again to get the supernatant;

[0033] (2) Add 0.003% amylase to the supernatant, and perform enzymatic hydrolysis for 30 minutes;

[0034] (3) Add the supernatant after enzymolysis to the Bacillus fermentation medium after passing through a strongly acidic styrene-based cation exchange column.

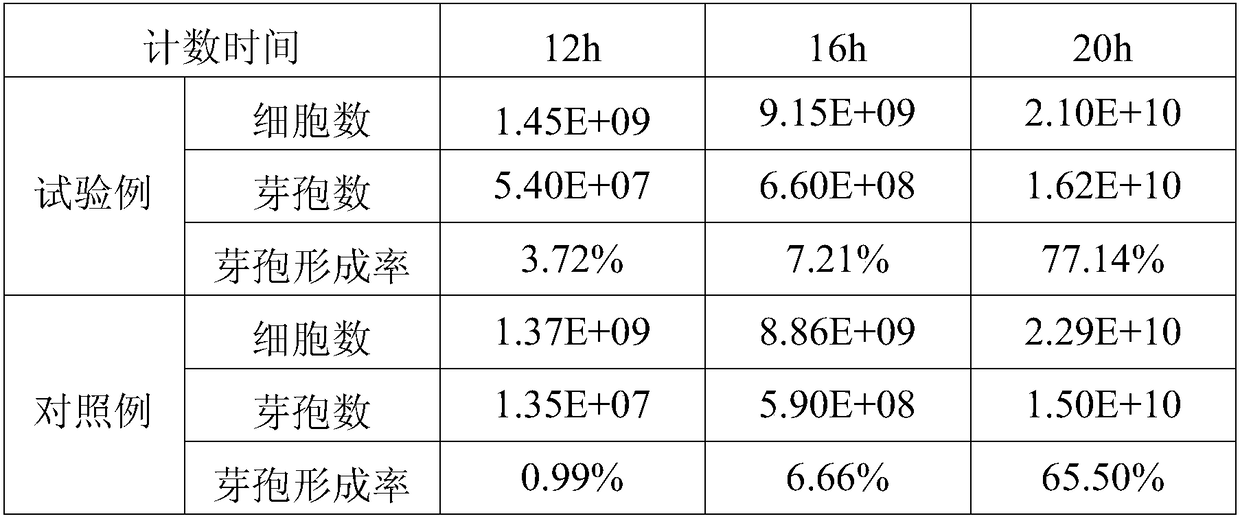

[0035] The treatment liquid in embodiment 1-3 is carried out physical and chemical index analysis, wherein total nitrogen adopts Kjeldahl method to detect, amino nitrogen adopts formaldehyde titration method to detect, total sugar adopts anthrone determination method, reducing sugar uses reducing sugar detector, The phosphorus-molybdenum blue colorimetric method was used for dissolving phosphorus, and the degree of protein hydrolysis refers to the ratio of amino nitrogen to total nitrogen. The test results are shown in the table belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com