Method for preparing sulfide composite nano film

A nano-film, sulfide technology, applied in chemical instruments and methods, copper sulfide, nickel sulfide, etc., can solve the problems of limited material structure and performance selection, and achieve uniform and stable electrical performance, high repeatability, and morphology. the effect of the rule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

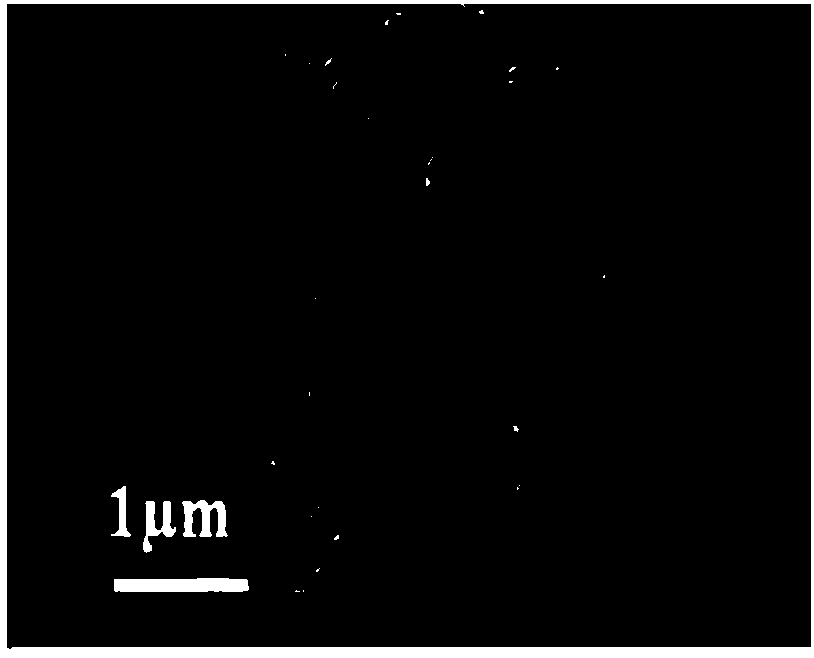

[0038] 1) Preparation of Co 9 S 8 nanoneedle array

[0039] Prepare 60mL reaction aqueous solution, this solution contains 6.25wt% Urea (urea), 0.15M Co(Cl) 2 ·6H 2 O (cobaltous chloride hexahydrate), the carbon cloth cleaned in step 1) was ultrasonicated for 30 minutes in the above reaction aqueous solution to make its surface fully contact with the solution, and then placed in a 100mL reaction kettle containing the above reaction solution, at 90°C Under the conditions of reaction for 3 h, cooled to room temperature, a light pink film was obtained on the surface of the carbon cloth, the sample was rinsed with deionized water, and after drying, the Co 9 S 8 Hydrates of Nanoneedle Arrays.

[0040] Prepare 60mL of 0.01M aqueous solution of sodium sulfide nonahydrate, the Co obtained above 9 S 8 The hydrate of the nanoneedle array was placed in a 100mL reaction kettle containing a reaction aqueous solution, reacted at 180°C for 10h, cooled to room temperature, and a black fi...

Embodiment 2

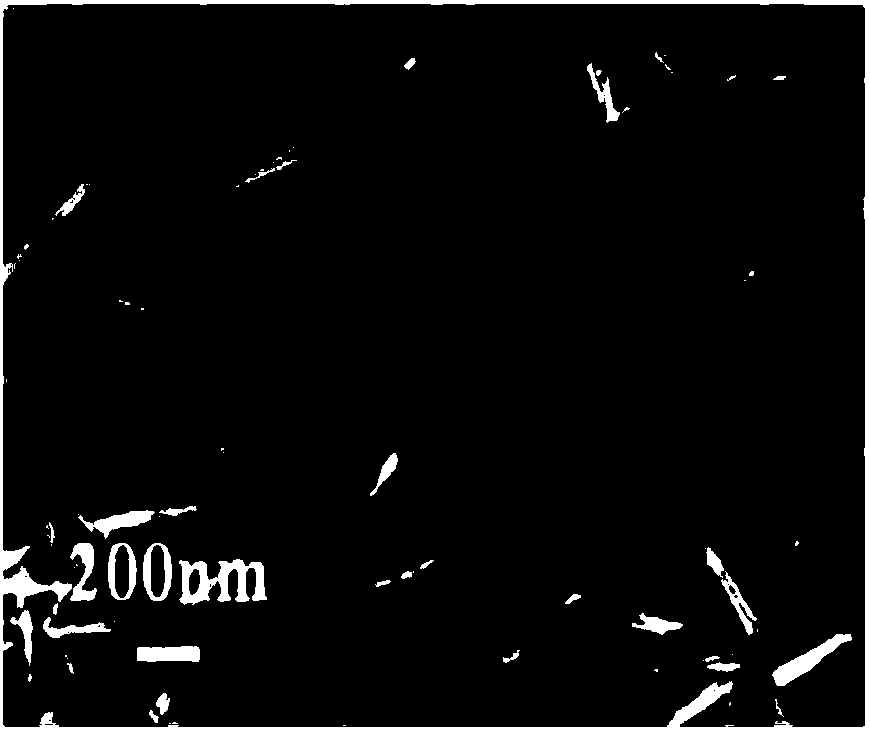

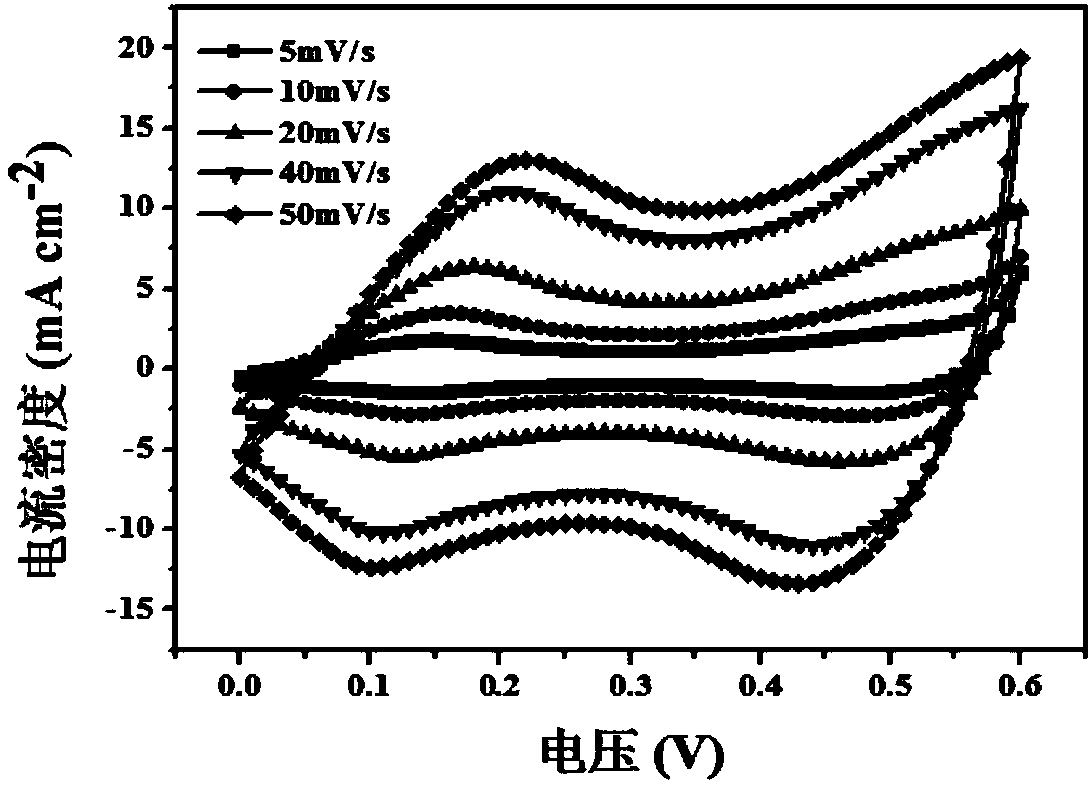

[0045] Repeat the 1) step of embodiment 1, prepare 60mL reaction aqueous solution, this aqueous solution contains the thiourea of 0.01M copper nitrate trihydrate and 0.05M, the above-mentioned long have Co 9 S 8 Put the carbon cloth with nanoneedle structure into a 100mL reaction kettle containing the above-mentioned reaction solution, and react at 150°C for 2 hours. After the reaction, cool to room temperature to obtain a black film with a darker color than the sample in Example 1, rinse with deionized water Samples were dried to obtain CuS nanosheets modified Co 9 S 8 Nano needle-like three-dimensional composite structure. Such as Figure 5 , 6 As shown, it can be seen that the CuS nanosheets are uniformly distributed on the Co 9 S 8 Around the array, its length is about 300nm. Such as Figure 7 As shown, further XRD characterization can also see that the diffraction peaks of the sample match the standard PDF card of CuS.

[0046] Repeat the 2) step of embodiment ...

Embodiment 3

[0048] Repeat the 1) step of embodiment 1, prepare 60mL reaction aqueous solution, this aqueous solution contains the thiourea of 25mg sodium molybdate dihydrate and 50mg, the above-mentioned long have Co 9 S 8 Put the carbon cloth with nanoneedle structure into a 100mL reaction kettle containing the above-mentioned reaction solution, and react at 200°C for 24 hours. After the reaction, cool to room temperature to obtain a black film with a darker color than the sample in Example 1. Rinse with deionized water sample, dried to get MoS 2 Nanosheet-modified Co 9 S 8 Nano needle-like three-dimensional composite structure. Such as Figure 10 and 11 As shown, MoS 2 The nanosheets are uniformly distributed on the Co 9 S 8 Around the array, its length is about 50nm. Such as Figure 12 As shown, further XRD characterization can also see that the diffraction peaks of the sample are consistent with those of MoS 2 The standard PDF card matches.

[0049] Repeat the 2) step of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com