A method for modifying the surface of battery positive electrode materials by using a coupling agent

A battery positive electrode and electrode material technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., to achieve the effect of improving cycle stability and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

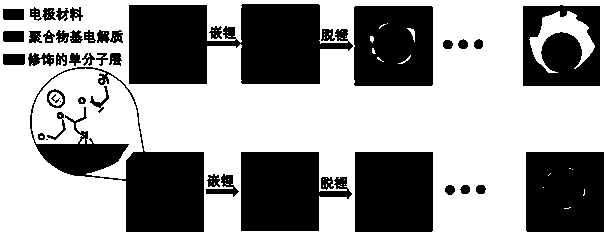

[0028] This embodiment provides a method for modifying the surface of the positive electrode material of the battery using a coupling agent, such as figure 1 As shown, the method steps are as follows:

[0029] 1. Weigh lithium manganese oxide (LiMn 2 o 4 ) material, put it into a vacuum drying oven for drying treatment.

[0030] 2. Completely dissolve 20g of dry lithium manganate in 30% H 2 o 2 In the aqueous solution, it was refluxed and extracted at 106° C. after standing for 20 minutes.

[0031] 3. Dissolve 5g of γ-(2,3-propylene oxide)propyltrimethoxysilane in 60mL of water-ethanol mixture, stir evenly, and add the lithium manganate material prepared in step 2 to make the two After extensive contact for 3 h, the solution was filtered and dried, and the material was vacuum dried at 80 °C for 12 h.

[0032] 4. Weigh 2.5g of polyoxyethylene and dissolve it in anhydrous acetonitrile, then add 0.9g of LiN(CF 3 SO 3 ) 2 After mixing, stir for 12 hours, and then disperse...

Embodiment 2

[0035] This embodiment provides a method for modifying the surface of the positive electrode material of the battery using a coupling agent, such as figure 1 As shown, the method steps are as follows:

[0036] 1. Weigh lithium cobalt oxide (LiCoO 2 ) material, put it into a vacuum drying oven for drying treatment.

[0037] 2. Completely dissolve 20g of dry lithium cobaltate in 30% H 2 o 2 In the aqueous solution, it was refluxed and extracted at 106° C. after standing for 20 minutes.

[0038] 3. Dissolve 5g of γ-aminopropyltriethoxysilane in 60mL of water-ethanol mixture, stir evenly, and add the lithium cobaltate material prepared in step 2. After the two are fully contacted for 3 hours, the solution After drying by filtration, the material was vacuum dried at 80 °C for 12 hours.

[0039] 4. Weigh 2.5g of polyacrylonitrile and dissolve it in acetone, then add 0.9g of LiPF to it 6After mixing, stir for 12 hours, and then disperse the material obtained in Step 3 and 2.5 g...

Embodiment 3

[0041] This embodiment provides a method for modifying the surface of the positive electrode material of the battery using a coupling agent, such as figure 1 As shown, the method steps are as follows:

[0042] 1. Weigh lithium nickel manganese oxide (LiNi 0.5 mn 1.5 o 4 ) material, put it into a vacuum drying oven for drying treatment.

[0043] 2. Completely dissolve 20g of dried lithium nickel manganese oxide in 30% H 2 o 2 In the aqueous solution, it was refluxed and extracted at 106° C. after standing for 20 minutes.

[0044] 3. Dissolve 5g of γ-aminopropyltriethoxysilane in 60mL of water-ethanol mixture, stir evenly, and add the lithium nickel manganese oxide material prepared in step 2. After the two are fully contacted for 3 hours, put The solution was dried by filtration and the material was dried under vacuum at 80°C for 12 hours.

[0045] 4. Weigh 2.5g of polymethyl methacrylate and dissolve it in acetone, then add 0.9g of LiPF to it 6 After mixing, stir for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com