Open-loop flow cooling alkali metal vapor laser gain generator

A laser gain and alkali metal technology, applied in the field of lasers, can solve the problems that cannot meet the actual power system requirements, affect the continuous operation life of the system, and achieve uniform heating, and achieve convenient heating and precise temperature control, and meet the flow heat dissipation requirements Effects of flexible gas pressure and flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

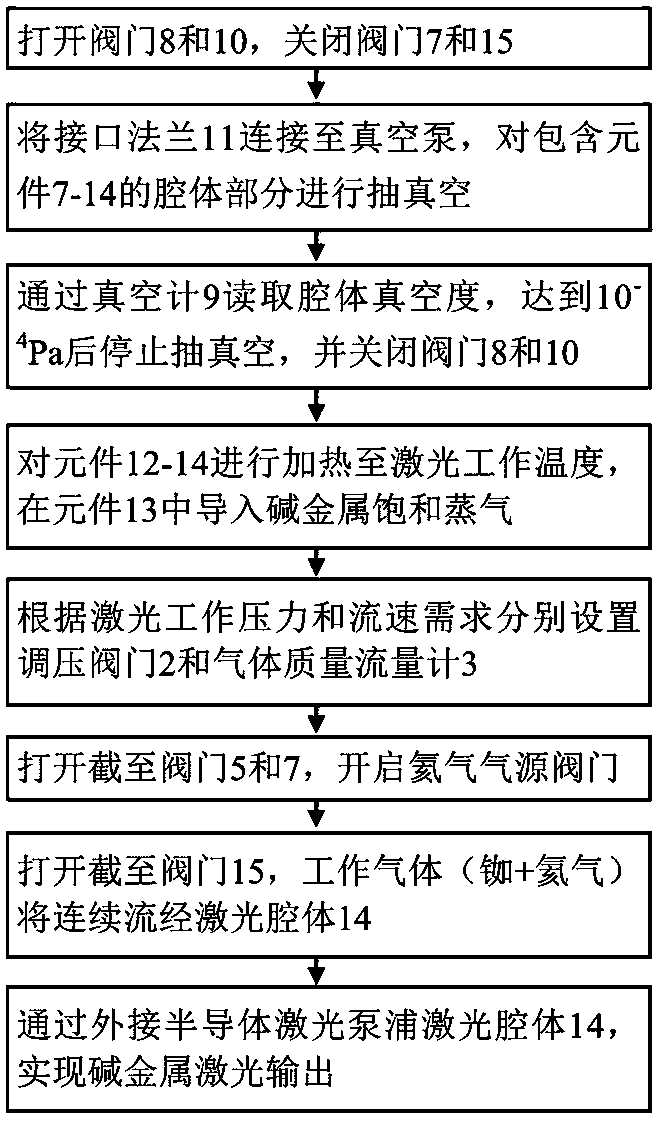

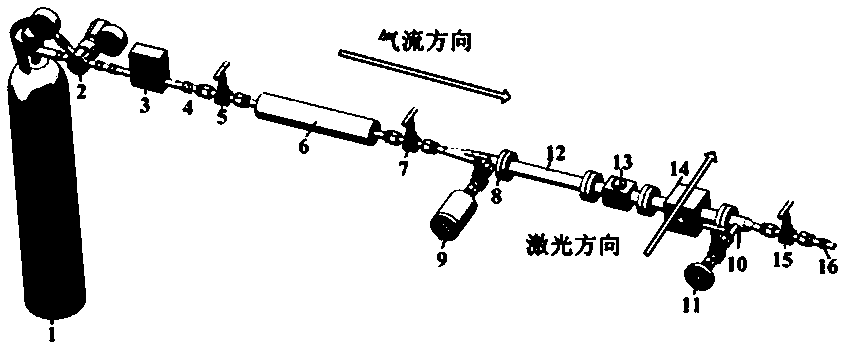

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] The open-loop flow heat dissipation alkali metal vapor laser gain generator of the present invention includes a buffer gas storage source 1, a gas pressure and flow control device, a gas purification device, a gas heating device, a vacuum acquisition and detection device, a mixing chamber 13 and a laser Chamber 14; the buffer gas in the buffer gas storage source 1 is regulated by the gas pressure and flow control device and then flows through the gas purification device at the required pressure and flow for purification. The purified gas is mixed with the alkali metal in the mixing chamber 13 The atomically saturated vapor is evenly mixed and flows into the laser chamber 14, which is pumped by an external semiconductor laser to generate laser output. During the laser operation process, waste heat is generated due to the quantum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com