Enteric sustained release oxytetracycline calcium premix and preparation method thereof

A technology of oxytetracycline calcium and premix, which is applied in the direction of active ingredients of tetracycline, microcapsules, non-active ingredients of oil/fat/wax, etc., can solve the problems of low bioavailability of oxytetracycline, and improve palatability, Effects of inhibiting reproduction and increasing mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

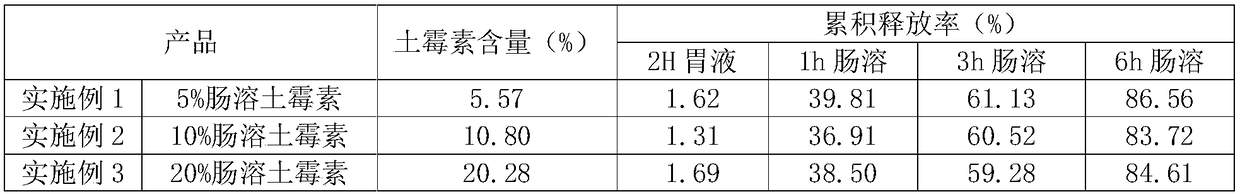

Embodiment 1

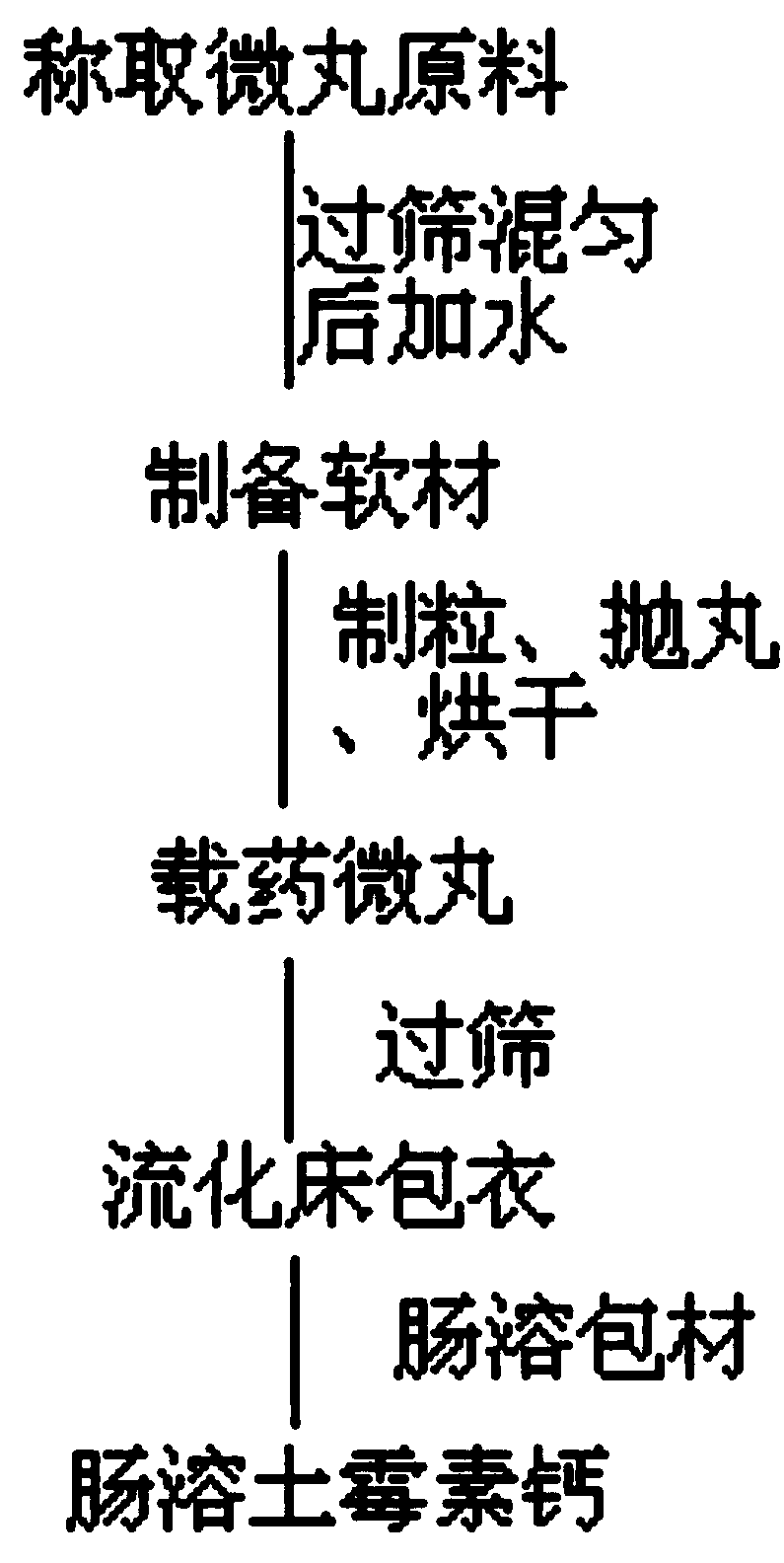

[0024] Such as figure 1 Shown, a kind of preparation method of enteric-coated slow-release oxytetracycline calcium premix comprises steps:

[0025] 1) Take by weight the ball core raw material, 5kg oxytetracycline, 10kg hydroxypropyl methylcellulose, 10kg chitosan and 40kg calcium carbonate, mix and stir evenly after pulverizing 80 mesh sieves respectively, add 10kg water , made of soft material,

[0026] 2) Add the soft material into a screw extruder, use a sieve plate with an aperture of 0.3mm, extrude the strips, transfer the obtained strips into a spheronizer, control the spheronization rate to 1000rpm, and roll them into pellets. The pellets were dried at 60°C, the water content was controlled within 8%, and after drying, they passed through a vibrating sieve with a screen mesh of 30 mesh to obtain oxytetracycline calcium pills;

[0027] 3) take the enteric coating layer by weight percentage, get 10kg carnauba wax, 20kg palm oil ester, be all dissolved in the 15kg polye...

Embodiment 2

[0029] Such as figure 1 Shown, a kind of preparation method of enteric-coated slow-release oxytetracycline calcium premix comprises steps:

[0030] 1) Take by weight percentage 10kg oxytetracycline, 10kg hydroxypropyl methylcellulose, 15kg chitosan and 25kg calcium carbonate, pulverize respectively and mix and stir evenly after crossing 80 mesh sieves, and then add 25 kg of ball core. % of water, made of soft materials,

[0031] 2) Add the soft material into a screw extruder, use a sieve plate with an aperture of 0.3mm, extrude the strips, transfer the obtained strips into a spheronizer, control the spheronization rate to 1000rpm, and roll them into pellets. The pellets are dried at 65° C., the water content is controlled within 8%, and after drying, they are passed through a vibrating sieve with a screen mesh of 30-50 mesh to obtain oxytetracycline calcium pellets;

[0032] 3) take the enteric coating layer by weight percentage, get 15kg carnauba wax, 20kg palm oil ester, b...

Embodiment 3

[0034] Such as figure 1 Shown, a kind of preparation method of enteric-coated slow-release oxytetracycline calcium premix comprises steps:

[0035] 1) Take by weight percentage 20kg oxytetracycline, 15kg hydroxypropyl methylcellulose, 15kg chitosan and 10kg calcium carbonate, pulverize respectively and mix and stir evenly after crossing 80 mesh sieves, then add ball core weight 20kg -30% water, made into soft materials,

[0036] 2) Add the soft material into a screw extruder, use a sieve plate with an aperture of 0.3mm, extrude the strips, transfer the obtained strips into a spheronizer, control the spheronization rate to 1000rpm, and roll them into pellets. The pellets are dried at 70° C., the water content is controlled within 8%, and after drying, they pass through a vibrating sieve with a sieve of 50 mesh to obtain oxytetracycline calcium pellets;

[0037]3) take the enteric coating layer by weight percentage, get 15kg carnauba wax, 20kg palm oil ester, be all dissolved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com