Preparation method of carbon quantum dots with changeable color and photothermal effect as well as product of preparation method and application of carbon quantum dots

A technology of photothermal effect and carbon quantum dots, which is applied in the direction of medical preparations containing active ingredients, color-changing fluorescent materials, preparations for in vivo experiments, etc., can solve rare problems, achieve low economic cost, inhibit tumor growth, and prepare The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Preparation of carbon quantum dots with variable color and photothermal effect:

[0042] Step 1. Weigh 1ml of black ink (Hero brand) into a 50mL beaker, add 19mL of deionized water, stir at 500rpm for 15min at 25°C, and the stirring speed is 450-650r / min.

[0043] Step 2, the stirred solution was transferred to a polytetrafluoroethylene hydrothermal reaction kettle, placed in a vacuum drying oven, and heated at a constant temperature of 200° C. for 12 hours.

[0044] Step 3, after the reaction, wait for the product to cool down to 25°C naturally.

[0045] Step 4, the obtained solution was placed in a 5ml centrifuge tube, then transferred to a high-speed centrifuge, centrifuged at a speed of 10000r / min for 15min, and then filtered with a 0.22μm microporous filter head to obtain a solution of carbon quantum dots.

[0046]Step 5, vacuum freeze-dry the obtained solution at a temperature of -55° C. for 26 hours and a vacuum of 9.6 Pa to obtain a color-changing fluorescent c...

Embodiment 2

[0052] Preparation of carbon quantum dots with variable color and photothermal effect:

[0053] Step 1. Weigh 1ml of black ink (Hero brand) into a 50mL beaker, add 19mL of deionized water, stir at 500rpm for 15min at 25°C, and the stirring speed is 450-650r / min.

[0054] Step 2: Transfer the stirred solution to a polytetrafluoroethylene hydrothermal reaction kettle, place in a vacuum drying oven, and heat at a constant temperature of 200° C. for 14 hours.

[0055] Step 3, after the reaction, wait for the product to cool down to 25°C naturally.

[0056] Step 4, the obtained solution was placed in a 5ml centrifuge tube, then transferred to a high-speed centrifuge, centrifuged at a speed of 10000r / min for 15min, and then filtered with a 0.22μm microporous filter head to obtain a solution of carbon quantum dots.

[0057] Step 5, vacuum freeze-dry the obtained solution at a temperature of -55° C. for 26 hours and a vacuum of 9.6 Pa to obtain a color-changing fluorescent carbon qua...

Embodiment 3

[0062] Preparation of carbon quantum dots with variable color and photothermal effect:

[0063] Step 1. Weigh 1ml of black ink (Hero brand) into a 50mL beaker, add 19mL of deionized water, and stir at 500rpm for 15min at 25°C.

[0064] Step 2: Transfer the stirred solution to a polytetrafluoroethylene hydrothermal reaction kettle, place it in a vacuum drying oven, and heat at a constant temperature of 200° C. for 10 h.

[0065] Step 3, after the reaction, wait for the product to cool down to 25°C naturally.

[0066] Step 4, the obtained solution was placed in a 5ml centrifuge tube, then transferred to a high-speed centrifuge, centrifuged at a speed of 10000r / min for 15min, and then filtered with a 0.22μm microporous filter head to obtain a solution of carbon quantum dots.

[0067] Step 5, vacuum freeze-dry the obtained solution at a temperature of -55° C. for 26 hours and a vacuum of 9.6 Pa to obtain a color-changing fluorescent carbon quantum dot powder.

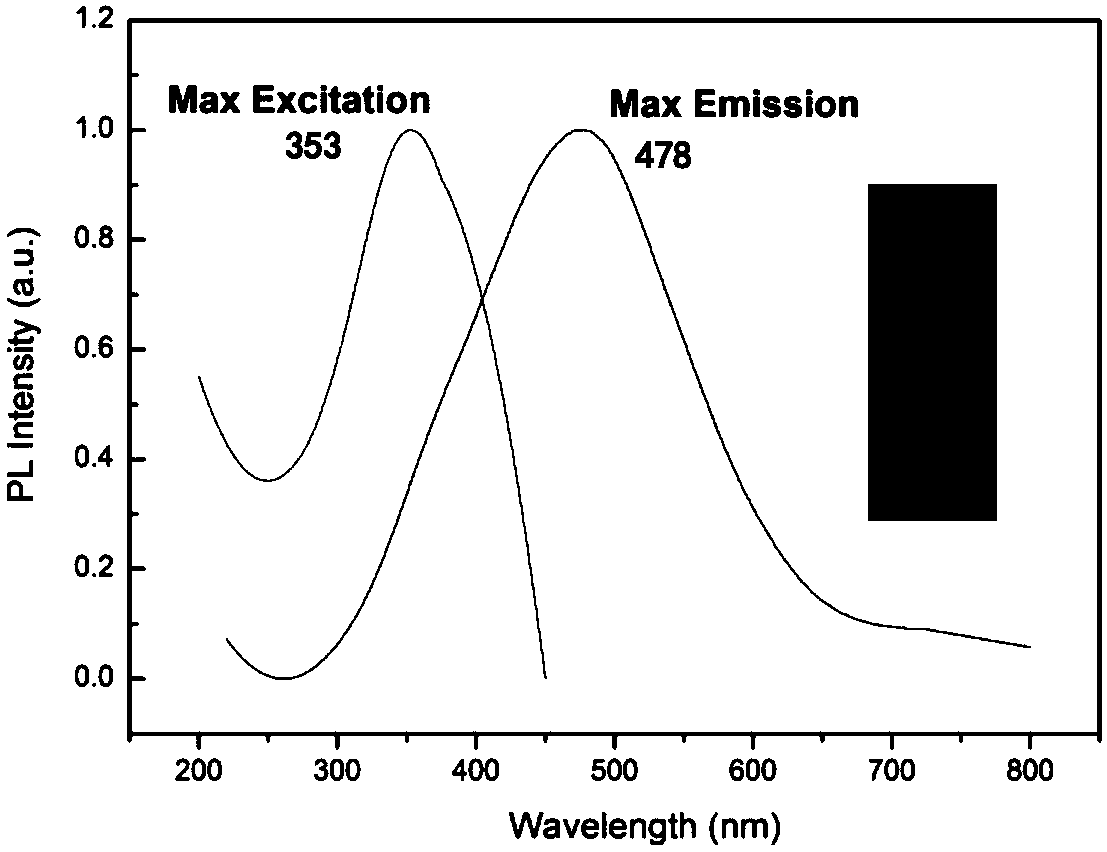

[0068] Figure 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com