Colored photosensitive resin composition, color filter and display device having the same

A technology of photosensitive resin and composition, applied in the direction of photosensitive materials, instruments, optics, etc. for opto-mechanical equipment, can solve problems such as poor orientation, difficulty, and poor voltage retention rate, and achieve excellent characteristics, voltage retention rate and Excellent brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

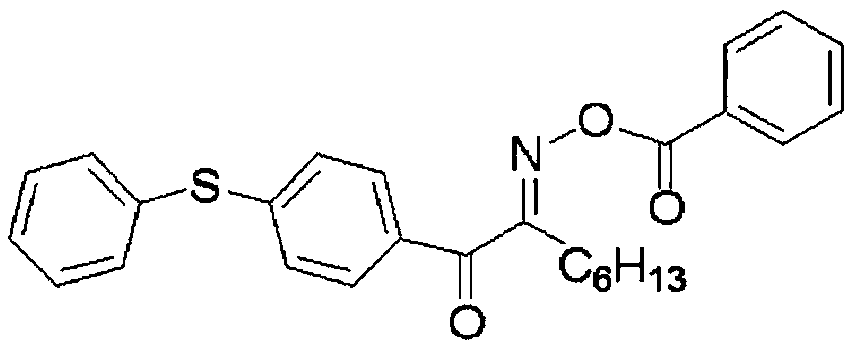

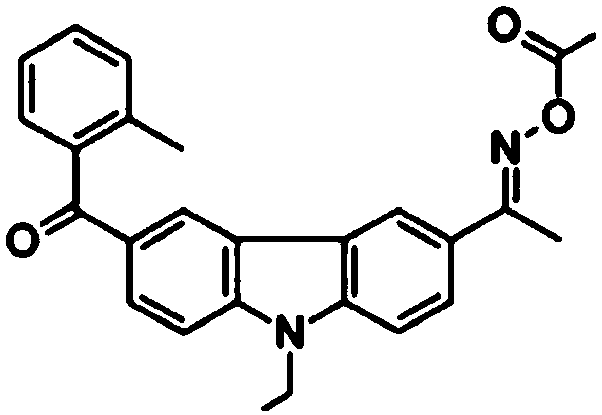

Method used

Image

Examples

Synthetic example 1

[0117] Synthesis example 1. Synthesis of alkali-soluble resin (B-1)

[0118] 120 parts by weight of propylene glycol monomethyl ether acetate, 80 parts by weight of propylene glycol monomethyl ether, azobisisobutyronitrile (Azobisisobutyronitrile, AIBN) 2 parts by weight, 13 parts by weight of acrylic acid, 10 parts by weight of benzyl methacrylate, 57 parts by weight of 4-methylstyrene, 20 parts by weight of methyl methacrylate, 3 parts by weight of n-dodecyl mercaptan parts by weight, and carry out nitrogen replacement. Thereafter, the temperature of the reaction solution was raised to 110° C. while stirring, and the reaction was carried out for 6 hours. The acid value of the solid content of the alkali-soluble resin synthesized in this way was 100.2 mgKOH / g, and the weight average molecular weight Mw measured by GPC was about 15,110.

manufacture example

[0119] Manufacture of pigment dispersion composition

[0120]

[0121] Using a bead mill, 12.0 parts by weight of C.I. Pigment Green 62 as a pigment, 4 parts by weight of LPN-6919 (manufactured by BYK) as a pigment dispersant, and 84 parts by weight of propylene glycol methyl ether acetate as a solvent Each part was mixed / dispersed for 12 hours to prepare a pigment dispersion liquid M1.

[0122]

[0123] Using a bead mill, 12 parts by weight of C.I. Pigment Green 63 as a pigment, 4 parts by weight of LPN-6919 (manufactured by BYK) as a pigment dispersant, and 84 parts by weight of propylene glycol methyl ether acetate as a solvent were mixed / Dispersion was carried out for 12 hours to prepare a pigment dispersion liquid M2.

[0124]

[0125] Using a bead mill, 12 parts by weight of C.I. Pigment Green 7 as a pigment, 4 parts by weight of LPN-6919 (manufactured by BYK) as a pigment dispersant, and 84 parts by weight of propylene glycol methyl ether acetate as a solvent w...

Embodiment 1

[0132] 15.43 parts by weight of the above , 12.50 parts by weight of , 12.47 parts by weight of the resin of , 4.64 parts by weight of KAYARAD DPHA (manufactured by Nippon Kayaku), 1.40 parts by weight of OXE-02 (manufactured by BASF Corporation) and 53.56 parts by weight of propylene glycol monomethyl ether acetate were mixed to prepare a colored photosensitive resin composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com