Processing method for improving threshold voltage of thin film transistor (TFT) device

A processing method and threshold voltage technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as crystal structure damage, polysilicon channel film and GI film interface defects, interface unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

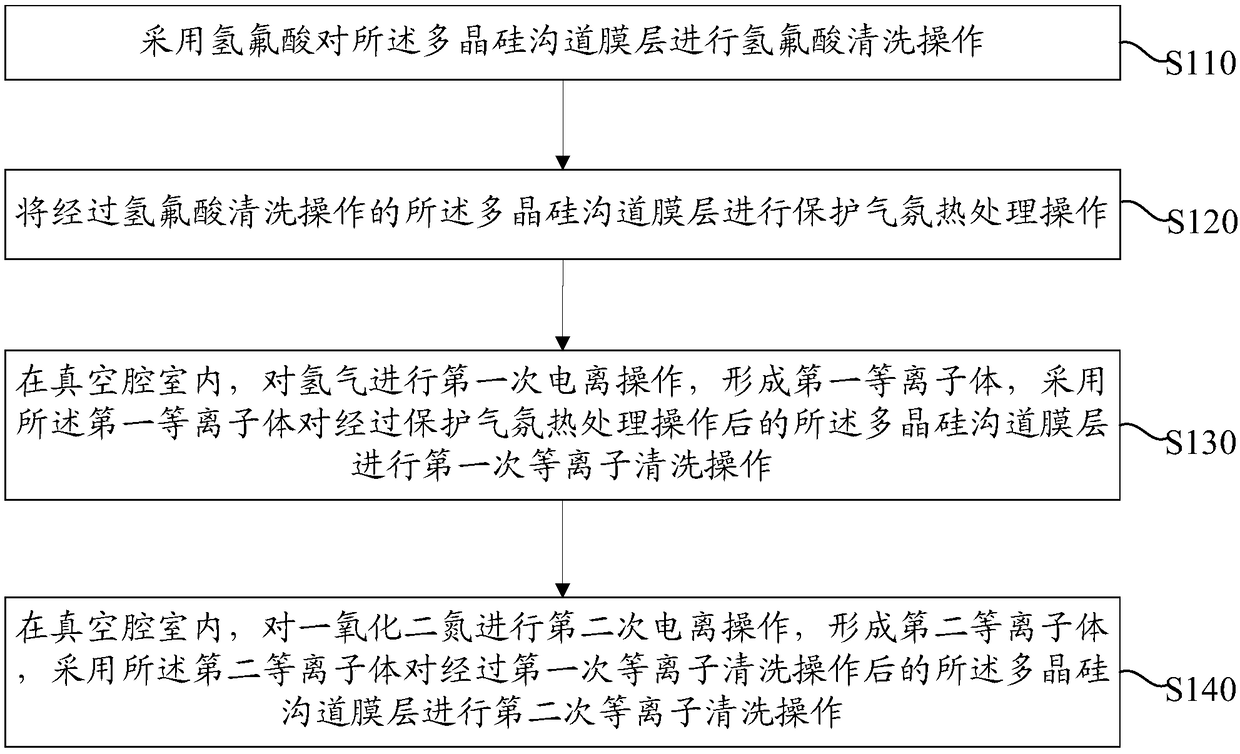

[0056] A processing method for improving the threshold voltage of a TFT device is applied before forming a gate insulating layer on a polysilicon channel film layer, and the processing method includes the following steps:

[0057] Using hydrofluoric acid to perform a hydrofluoric acid cleaning operation on the polysilicon channel film layer; wherein, the concentration of the hydrofluoric acid is 0.5%, and the duration of the hydrofluoric acid cleaning operation is 20 seconds;

[0058] The polysilicon channel film layer cleaned by hydrofluoric acid is subjected to a protective atmosphere heat treatment operation; wherein, the heat treatment atmosphere is nitrogen, the heat treatment pressure is 0.8 Torr, the heat treatment temperature is 400° C., and the heat treatment time is 1 min;

[0059] In the vacuum chamber, the hydrogen gas is ionized for the first time to form a first plasma, and the first plasma is used to perform the first plasma cleaning operation on the polysilicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com