Brazing material for repairing anode steel claw and preparation method thereof

A technology of anode steel claws and brazing materials, applied in welding/cutting medium/material, welding equipment, welding medium, etc., can solve the problems of affecting electrolysis efficiency, high resistivity, and anode carbon block falling off, and improve the contact area. , the effect of increasing the specific surface area and reducing the anode pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

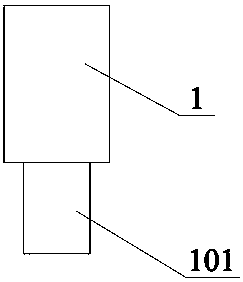

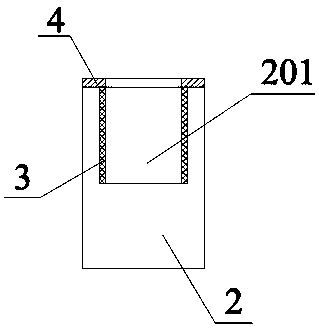

[0035] A brazing material for repairing anode steel claws, the brazing material includes a cylindrical brazing filler metal 3 and a semi-annular brazing filler metal 4 that are matched with the anode steel claw head 1 to be repaired and the round steel 2 for repairing , The corrosion section of the anode steel claw head 1 to be repaired is cut off, the lower end is processed with a boss 101, the round steel 2 replacing the corrosion section has the same diameter and the same length as the anode steel claw head 1, and a groove 201 is processed at the upper end. The cylindrical solder 3 is placed in the groove 201, and the semi-annular solder 4 is placed on the edge of the groove 201 of the round steel;

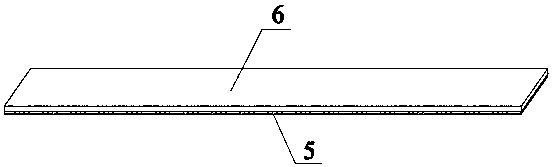

[0036] The cylindrical brazing filler metal 3 is formed by a thin strip of brazing filler metal 6 coated with a flux layer 5 on the surface, which is folded multiple times along the length direction into a short strip of brazing filler metal 7 with alternating brazing filler metal ...

Embodiment 2

[0052] A brazing material for repairing anode steel claws, the brazing material includes a cylindrical brazing filler metal 3 and a semi-annular brazing filler metal 4 that are matched with the anode steel claw head 1 to be repaired and the round steel 2 for repairing , The corrosion section of the anode steel claw head 1 to be repaired is removed, the lower end is processed with a boss 101, the round steel 2 replacing the corrosion section has the same diameter and the same length as the anode steel claw head 1, and a groove 201 is processed at the upper end. The cylindrical solder 3 is placed in the groove 201, and the semi-annular solder 4 is placed on the edge of the groove 201 of the round steel;

[0053] The cylindrical brazing filler metal 3 is a thin strip of brazing filler metal 6 coated with a flux layer 5 on its surface, which is folded several times along the length direction into a short strip of brazing filler metal 7 with alternating brazing filler metal and brazing...

Embodiment 3

[0069] A brazing material for repairing anode steel claws, the brazing material includes a cylindrical brazing filler metal 3 and a semi-annular brazing filler metal 4 that are matched with the anode steel claw head 1 to be repaired and the round steel 2 for repairing , The corrosion section of the anode steel claw head 1 to be repaired is removed, the lower end is processed with a boss 101, the round steel 2 replacing the corrosion section has the same diameter and the same length as the anode steel claw head 1, and a groove 201 is processed at the upper end. The cylindrical solder 3 is placed in the groove 201, and the semi-annular solder 4 is placed on the edge of the groove 201 of the round steel;

[0070] The cylindrical brazing filler metal 3 is a thin strip of brazing filler metal 6 coated with a flux layer 5 on its surface, which is folded several times along the length direction into a short strip of brazing filler metal 7 with alternating brazing filler metal and brazing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com