Method for removing phosphorus in water body by using adsorption of nano-lanthanum oxide modified alkali lignin

A technology of nanometer lanthanum oxide and alkali lignin is applied in the field of alkali lignin material adsorption and removal of orthophosphate in water to achieve the effects of improving adsorption effect, increasing temperature and improving adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The method for removing phosphorus in water by adsorption of alkali lignin modified by nanometer lanthanum oxide comprises the following steps:

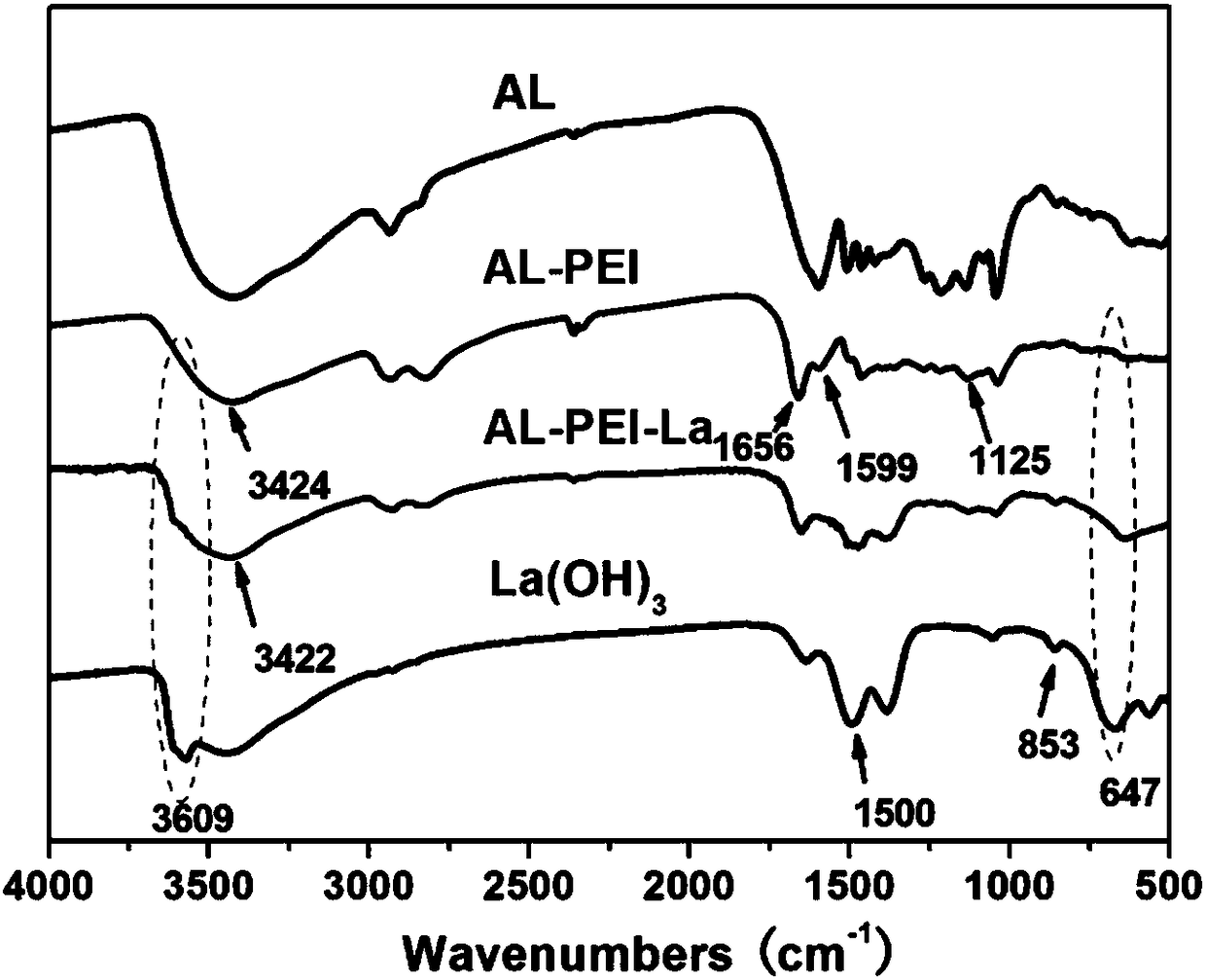

[0038] Step 1. Dissolve 5.0g alkali lignin in 100mL aqueous solution, add 4.0g polyethyleneimine (PEI, 99wt.%) and 4.0g formaldehyde (37wt.%) solution, get 20wt.% sodium hydroxide solution to adjust pH to 10.0-11.0, stir evenly, heat up to 50°C, react for 24h, filter with suction, wash several times until neutral, vacuum dry at 60°C to constant weight, and obtain alkali lignin grafted polyethyleneimine, denoted as AL- PEI.

[0039]Step 2. Add 2.0g AL-PEI to the mixed solution of 100mL absolute ethanol and distilled water (v / v=1:4), add 3.71g lanthanum chloride heptahydrate, and take 20wt.% sodium hydroxide solution Adjust the pH to 10.0-11.0, react at 60°C for 3 hours, and continue to react at room temperature for 24 hours. After cooling, the reaction product is fully washed with water and dried in vacuum to obtain nano-lanth...

Embodiment 4

[0047] The preparation of the alkali lignin adsorbent modified by nanometer lanthanum oxide comprises the following steps:

[0048] Step 1. Dissolve 5.0g alkali lignin in 100mL aqueous solution, add 5.0g polyethyleneimine (PEI, M.W.10000, 99wt.%) and 5.0g formaldehyde (37wt.%) aqueous solution, get 20wt.% of hydroxide Adjust the pH of the sodium solution to 10.0-11.0, stir evenly, then heat up to 50°C, react for 24 hours, filter with suction, wash several times until neutral, and vacuum-dry at 60°C to constant weight to obtain alkali lignin grafted polyethyleneimine, record Make AL-PEI.

[0049] Step 2. Add 2.0g AL-PEI to the mixed solution of 100mL absolute ethanol and distilled water (v / v=1:4), add 4.90g lanthanum chloride heptahydrate, and take 20wt.% sodium hydroxide solution Adjust the pH to 10.0-11.0, react at 60°C for 3 hours, and continue to react at room temperature for 24 hours. After cooling, the reaction product is fully washed with water and dried in vacuum to ob...

Embodiment 5

[0051] The alkali lignin AL-PEI-La modified by nano-lanthanum oxide synthesized in Example 1 was used as an adsorbent to adsorb and treat phosphorus-containing water. The initial concentration of phosphorus was 46.72mg P / L, and other adsorption conditions were the same as in Example 1. The variation law of adsorption amount with adsorption time was studied. The experimental results showed that the time for adsorption to reach equilibrium was 60min, and the equilibrium adsorption amount was 37.28mg P / g.

[0052] It can be seen that compared with the time for other adsorbents reported in the literature to reach adsorption equilibrium (ACF-LaFe (120min) (Chemical Engineering Journal, 2013, 215-216, 859-867.), ACF-LaOH (360min) (Chemical Engineering Journal, 2012 ,185–186,160-167.), MFC@La(OH)(240min)(Chemical Engineering Journal,2018,335,443-449.), Lanthanum-supported ordered mesoporous hollow silicon spheres (1440min)(Journal of Materials Chemistry A ,2014,2,8839-8848.)), the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com