Environment-friendly epoxy floor paint and preparation method thereof

An epoxy floor paint, an environmentally friendly technology, applied in coatings, anti-corrosion coatings, etc., can solve the problems of not being able to participate in the epoxy resin curing system, not meeting the requirements of green environmental protection, and canceration of human cells, and achieve excellent adhesion , Low curing shrinkage, good low temperature curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] In a preferred embodiment, the preparation method of the first component at least includes the following steps:

[0060] Add epoxy resin, methyl methacrylate, trifluoroethyl methacrylate, benzyl methacrylate and solvent into the reaction kettle in corresponding parts by weight, stir evenly, and add initiator, then raise the reaction temperature to The temperature is as high as 75°C, and the stirring reaction is carried out for 2 to 5 hours to obtain the reaction product. After cooling to room temperature, the filler, the color paste, and the active diluent are added to the reaction product in sequence, and the first component is obtained after stirring evenly.

[0061] In a preferred embodiment, the first component also includes an auxiliary agent; the auxiliary agent is selected from: antioxidant, defoamer, flame retardant, ultraviolet absorber, leveling agent, wetting agent Any one or a mixture of dispersants, defoamers, heat stabilizers.

[0062] The antioxidants ma...

Embodiment 1

[0085] Embodiment 1 of the present invention provides a kind of environment-friendly type epoxy floor paint, the preparation raw material of described environment-friendly type epoxy floor paint comprises at least the first component and the second component;

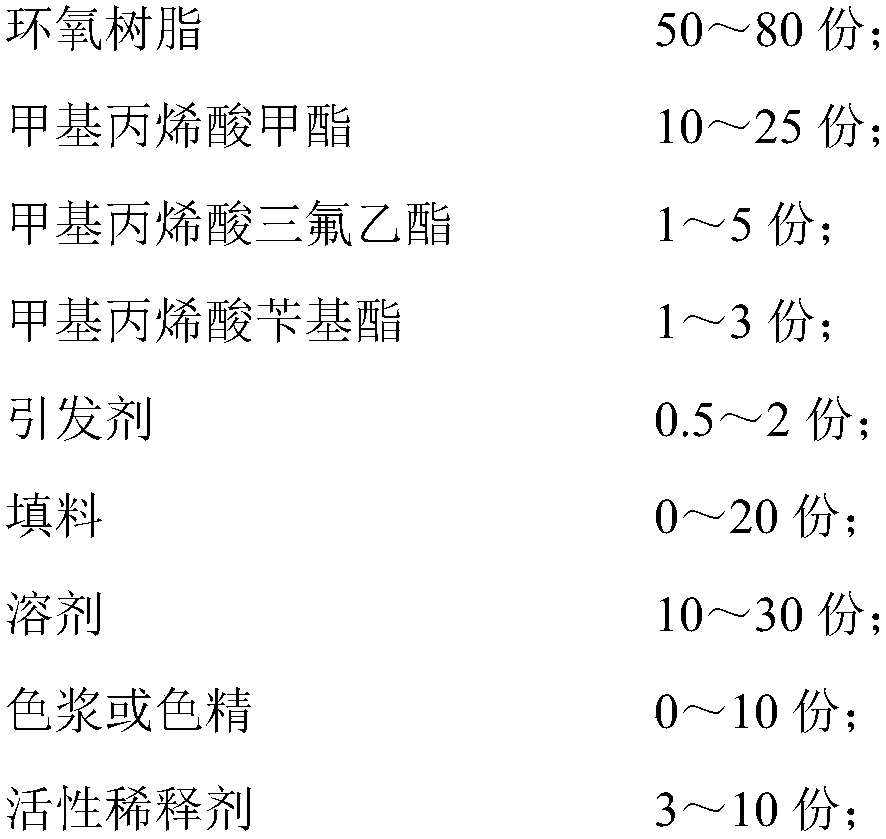

[0086] The first component, in parts by weight, includes the following raw materials:

[0087]

[0088]

[0089] Described epoxy resin is E-44 epoxy resin;

[0090] Described initiator is dibenzoyl peroxide;

[0091] The filler is calcium silicate;

[0092] Described solvent is ethanol;

[0093] The reactive diluent is triglycidyl ether of trimethylolpropane;

[0094] The second component includes the following raw materials in parts by weight:

[0095] 10 parts of epoxy curing agent;

[0096] The epoxy curing agent is medical stone compound.

[0097] The preparation method of described medical stone composite comprises the following steps at least:

Embodiment 2

[0106] Embodiment 2 of the present invention provides a kind of environment-friendly type epoxy floor paint, the preparation raw material of described environment-friendly type epoxy floor paint comprises at least the first component and the second component;

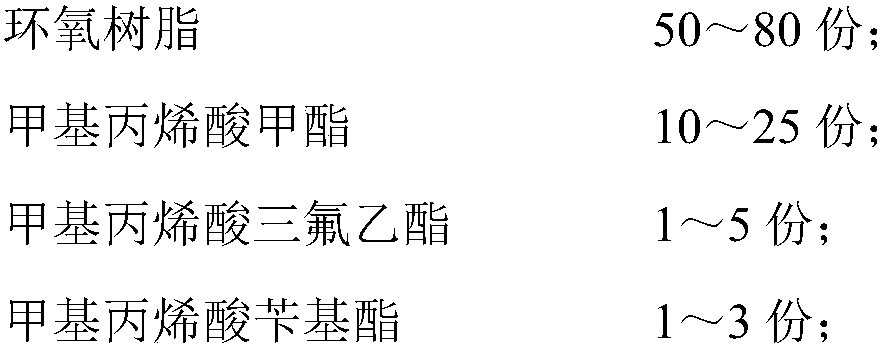

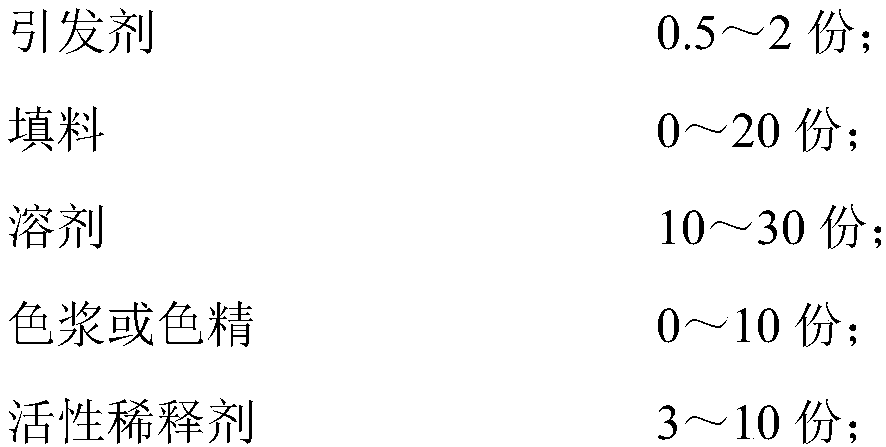

[0107] The first component, in parts by weight, includes the following raw materials:

[0108]

[0109] Described epoxy resin is E-44 epoxy resin;

[0110] Described initiator is dibenzoyl peroxide;

[0111] The filler is calcium silicate;

[0112] Described solvent is ethanol;

[0113] The reactive diluent is triglycidyl ether of trimethylolpropane;

[0114] The second component includes the following raw materials in parts by weight:

[0115] 40 parts of epoxy curing agent;

[0116] The epoxy curing agent is medical stone compound.

[0117] The preparation method of described medical stone composite comprises the following steps at least:

[0118] (1) Grinding the medical stone into a powder with a particle si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com