Preparation method of sea-urchin-shaped cobalt acid copper nanometer material of nickel foam load

A nanomaterial and nickel foam technology, which is applied in the field of preparation of copper cobaltate nanomaterials, can solve problems such as affecting the contact between ion and electron transport electrolyte and electrodes, achieve good morphology and electrochemical performance, improve electrochemical performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

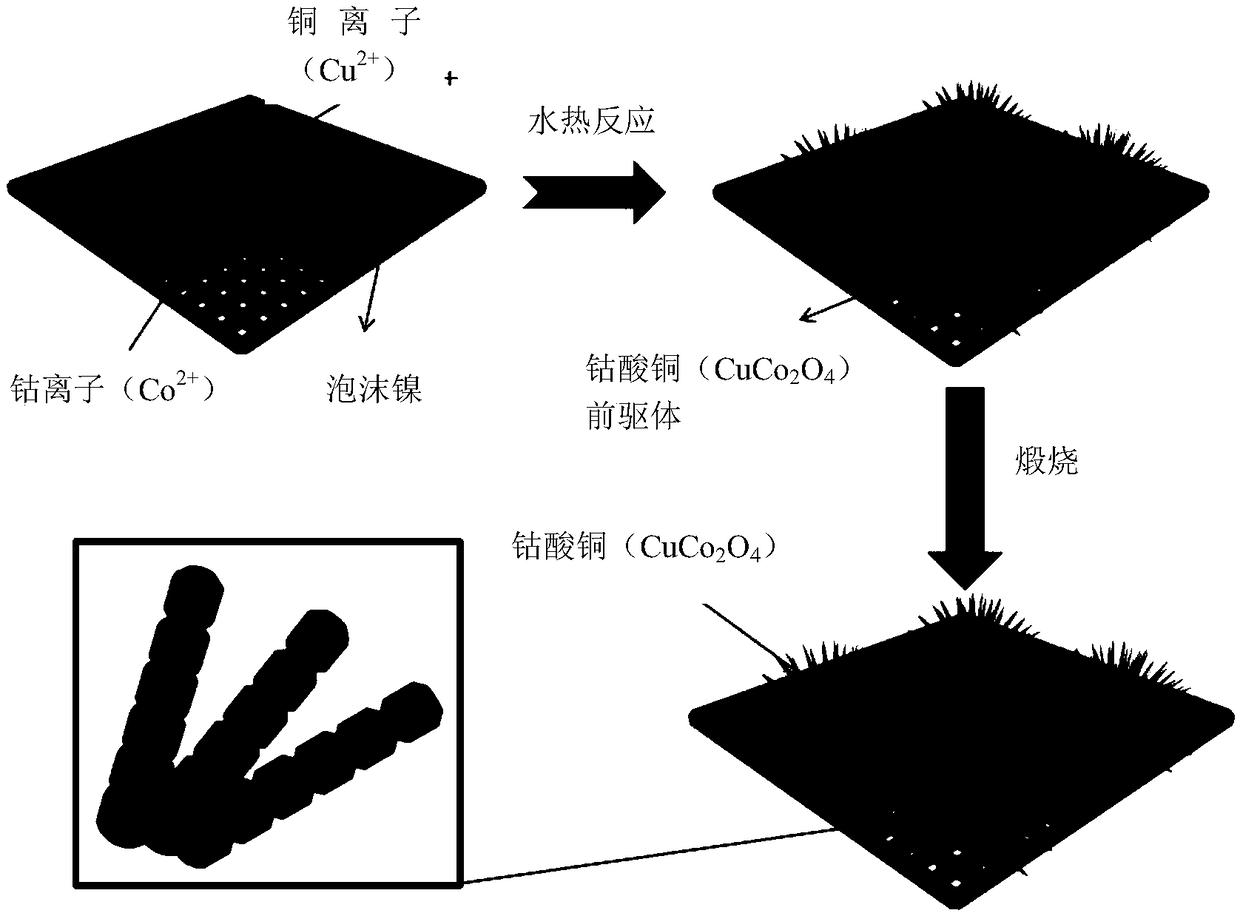

[0044] According to a non-limiting embodiment of the present invention, there is provided a kind of sea urchin-like lithium cobaltate (CuCo 2 o 4 ) A method for preparing a nanomaterial, the method comprising the following steps.

[0045] (1) After the sheet-shaped nickel foam is ultrasonically cleaned, it is placed in a drying oven for drying.

[0046] (2) Disperse cobalt nitrate hexahydrate into the solvent added with urea, and magnetically stir for 0.5 to 1.5 hours after ultrasonic cleaning at room temperature to form a dispersion solution, wherein the solvent is a mixed solution of absolute ethanol and deionized water, without The volume ratio of water ethanol to deionized water is 1:7, and the mass of cobalt nitrate hexahydrate and urea is 26-30:13.

[0047] (3) Add copper acetate monohydrate and ammonium fluoride to the dispersion solution obtained in step (2), and magnetically stir at room temperature for 0.5 to 1.5 hours to form a suspension, wherein the mass ratio o...

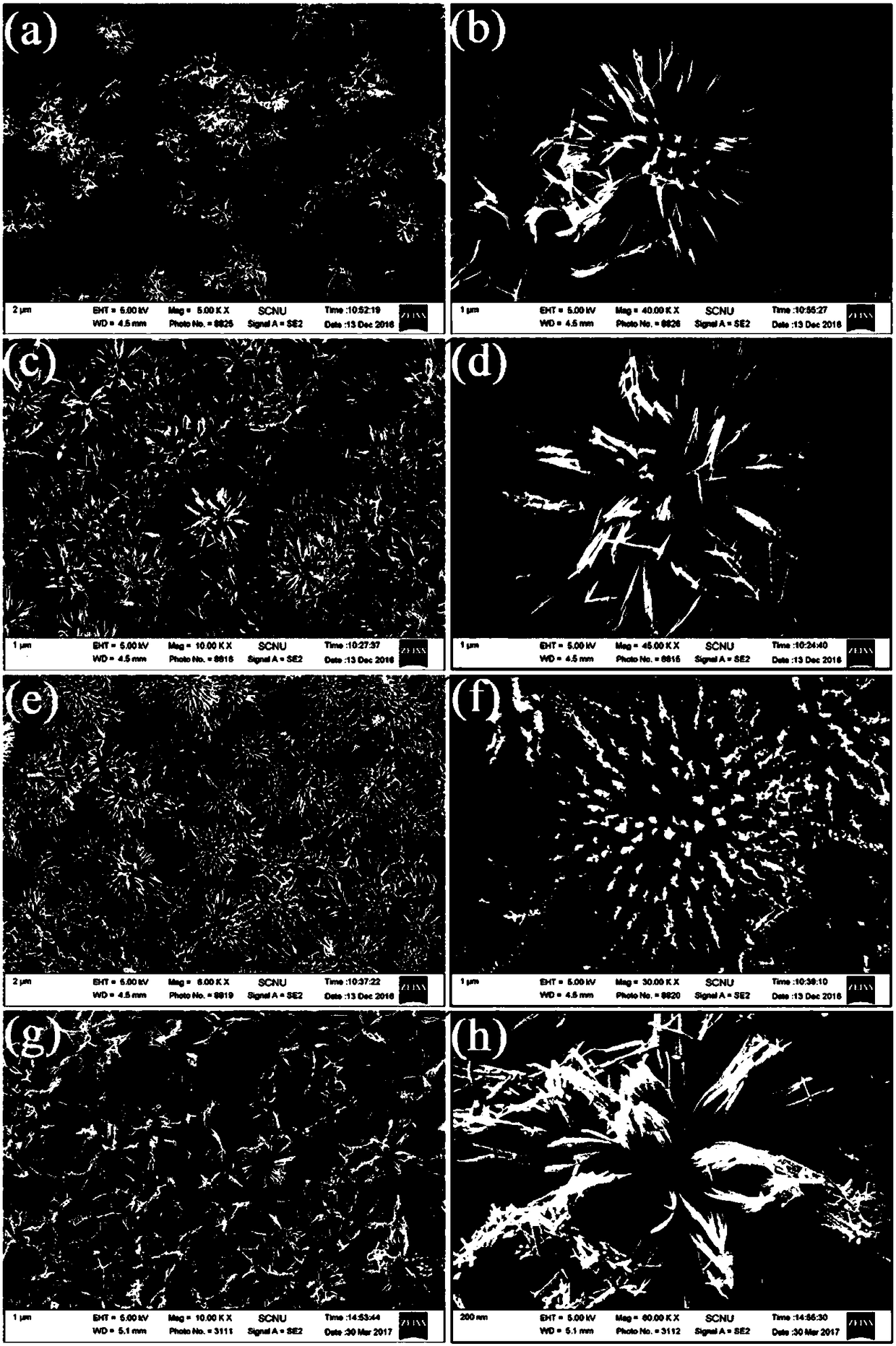

Embodiment 1

[0055] Step S1: Cut the nickel foam into a uniform size, the size is 3×4cm 2 , were washed with 3mol / L hydrochloric acid, acetone, absolute ethanol and deionized water successively in an ultrasonic cleaner for 30 minutes, 15 minutes, 10 minutes and 10 minutes, and then dried in a drying oven at 80°C for 12 Hour.

[0056] Step S2: Co(NO 3 ) 2 ·6H 2 O was dispersed into the solvent with urea added, the mass ratio of urea to solvent was 0.13:19, the solvent was mixed with absolute ethanol and deionized water according to the volume ratio of 1:7, ultrasonically cleaned at room temperature and heated at 300RPM The stirring speed was magnetically stirred for 1 h to obtain a dispersed solution.

[0057] Step S3: the Cu(CH 3 COO) 2 ·H 2 O and NH 4 Add F into the dispersion solution, continue magnetic stirring at room temperature at a stirring speed of 300 RPM for 1 h, and prepare a suspension. Among them, Co(NO 3 )2 ·6H 2 The mass ratio of O to urea is 0.29:0.13; Co(NO 3 )...

Embodiment 2

[0062] Except in step S3, Co(NO 3 ) 2 ·6H 2 Except that the mass ratio of O and urea is 0.3:0.13, other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com