Magnesium alloy biliary stent and preparation method thereof

A magnesium alloy stent and magnesium alloy technology are applied in the field of medical devices to achieve the effect of reducing the occurrence probability of bile leakage, excellent biocompatibility and reducing inflammatory response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

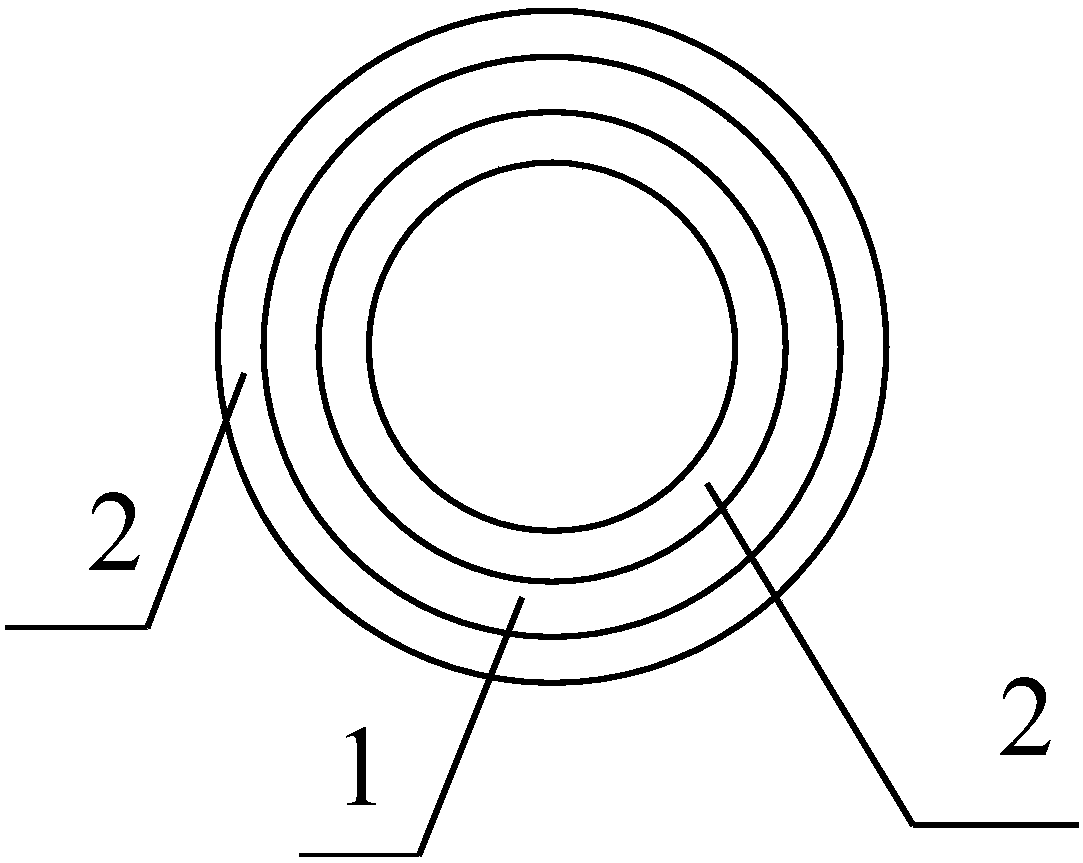

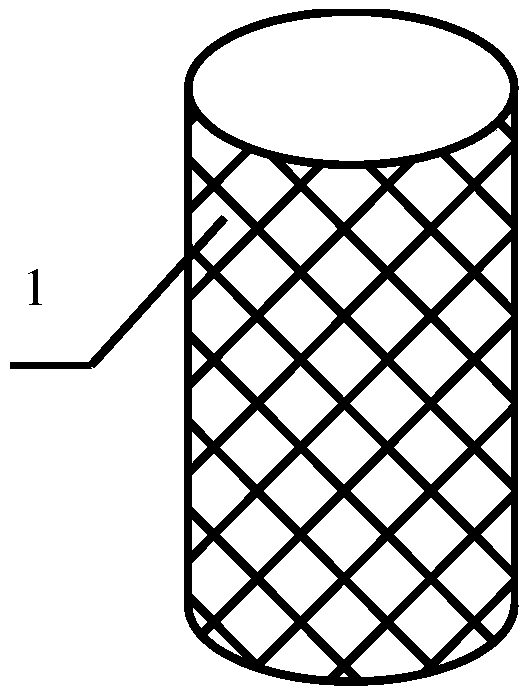

[0040] The invention discloses a preparation method of a magnesium alloy biliary stent, which comprises the following steps:

[0041] Step 1, preparing small intestinal submucosa (SIS, smallintestinalsubmucosa) matrix;

[0042] Step 1.1. Pretreatment: Take the fresh pig jejunum slaughtered within 4 hours, wash it repeatedly with water and put it in an ice pack for later use. Select the part with uniform lumen thickness, no damage to the tube wall and no lymph node attachment, and cut it into 10-12cm in length For the small segment, first use a scalpel to separate the edge of the mucosal layer, then use a vascular forceps wrapped in gauze to remove the serosa layer and muscular layer by frustrating, and wash it with 35-38°C water

[0043] Step 1.2, ultrasonic combined with chemical method processing:

[0044] Place the small intestinal submucosa treated in step 1.1 in 0.5% SDS physiological saline solution for 1.5-2h and sonicate at 35-38°C, then wash with 1mmol / L NaCl solutio...

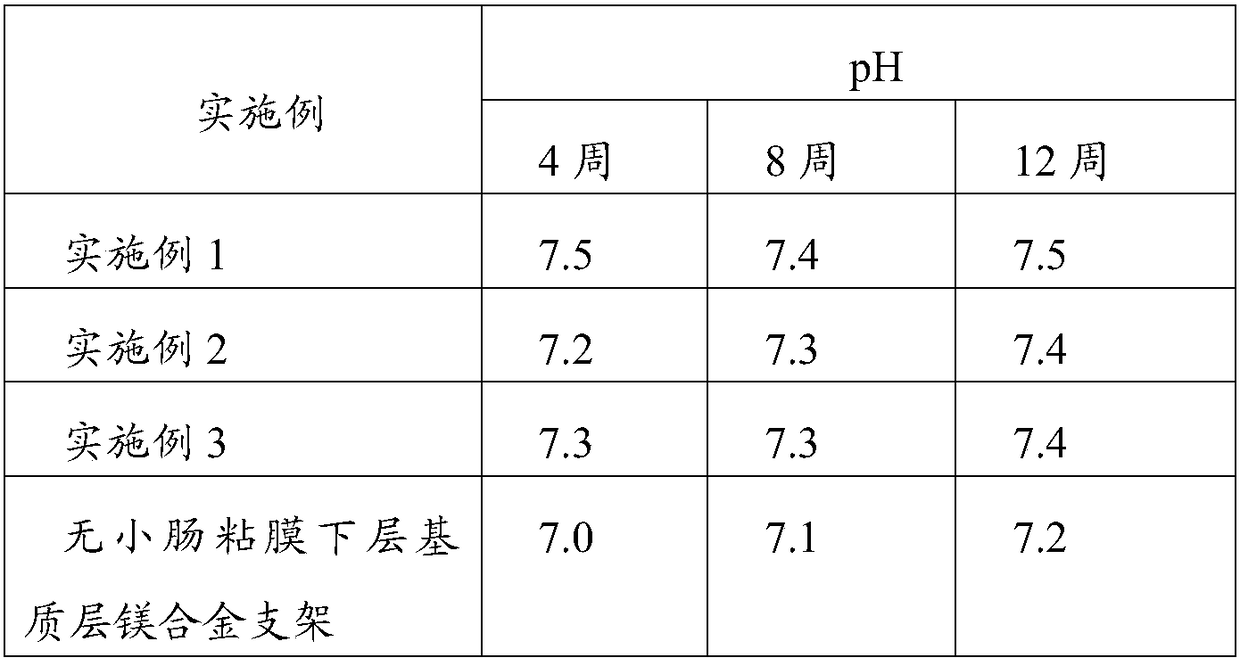

Embodiment 1

[0059] A preparation method of a magnesium alloy biliary stent, comprising the following steps:

[0060] Step 1, preparing small intestinal submucosa (SIS, smallintestinalsubmucosa) matrix;

[0061] Step 1.1. Pretreatment: Take fresh porcine jejunum slaughtered within 4 hours, rinse it repeatedly with water and put it in an ice pack for later use. Select the part with uniform lumen thickness, no damage to the tube wall, and no lymph node attachment, and cut it into small pieces with a length of 11 cm. First, use a scalpel to separate the edge of the mucosal layer, then use a vascular forceps wrapped in gauze to remove the serosa layer and muscular layer by frustrating, and wash it with 37°C water

[0062] Step 1.2, ultrasonic combined with chemical method processing:

[0063] Place the small intestinal submucosa treated in step 1.1 in 0.5% SDS physiological saline solution for 1.8 hours and sonicate at 37°C, then wash with 1 mmol / L NaCl solution 4 times;

[0064]Step 1.3. So...

Embodiment 2

[0077] A preparation method of a magnesium alloy biliary stent, comprising the following steps:

[0078] Step 1, preparing small intestinal submucosa (SIS, smallintestinalsubmucosa) matrix;

[0079] Step 1.1. Pretreatment: Take the fresh pig jejunum slaughtered within 4 hours, rinse it repeatedly with water and put it in an ice pack for later use. Select the part with uniform lumen thickness, no damage to the tube wall, and no lymph node attachment, and cut it into small pieces with a length of 10 cm. First, use a scalpel to separate the edge of the mucosal layer, then use a vascular forceps wrapped in gauze to remove the serosa layer and muscular layer by grinding, and wash it with 38°C water

[0080] Step 1.2, ultrasonic combined with chemical method processing:

[0081] The small intestinal submucosa treated in step 1.1 was placed in 0.5% SDS saline solution for 1.5 h, and the ultrasonic temperature was 38°C, and then washed 3 times with 1 mmol / L NaCl solution;

[0082] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com