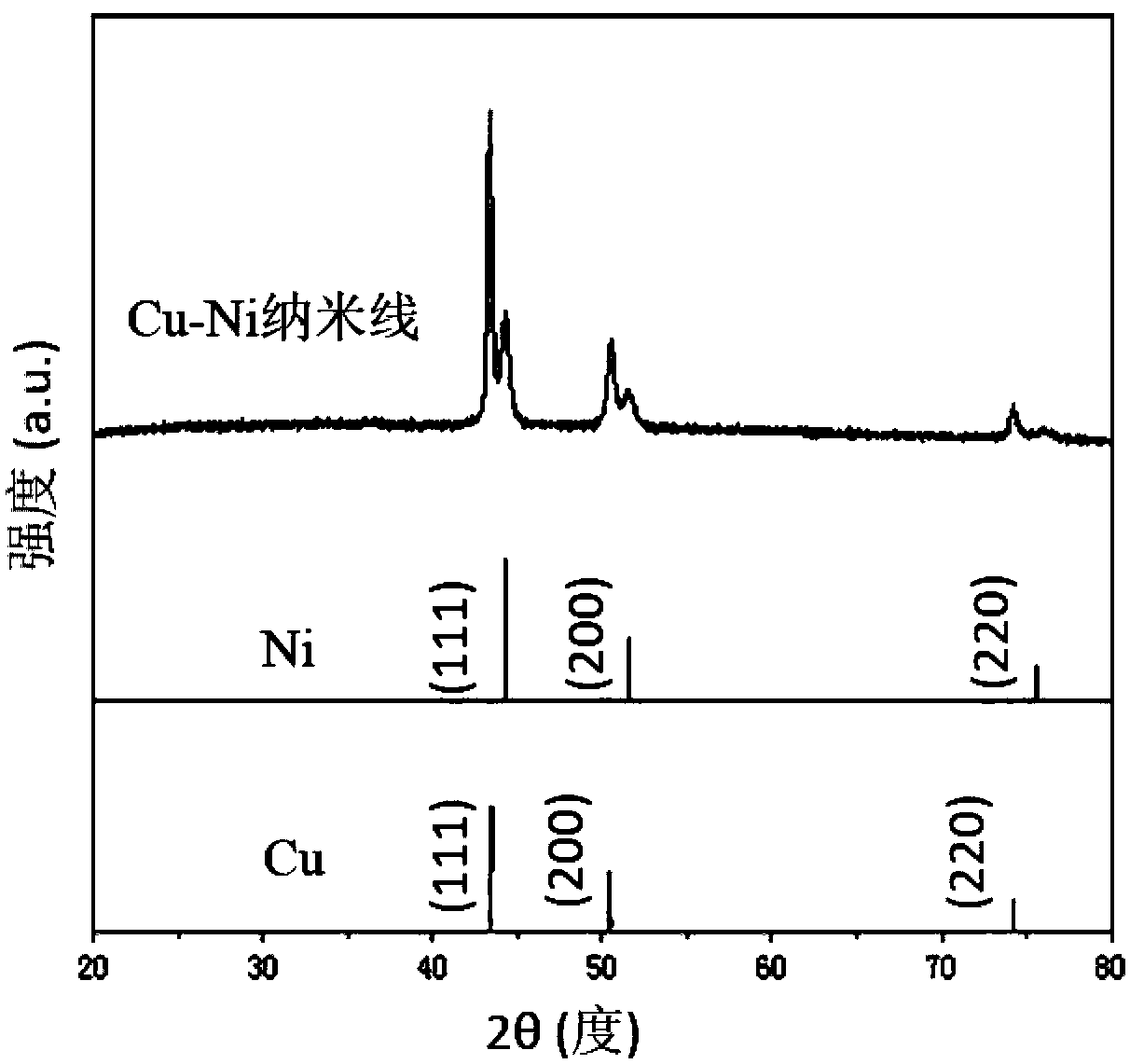

Linear Cu-Ni alloy nanocrystal and synthesis method thereof

A technology of alloy nanocrystals and synthesis methods, which is applied in the field of metal nano-controllable synthesis, can solve the problems of low potential of transition metals, difficulty in controlling reaction kinetics, and rarely reported controllable synthesis of bimetallic nanocrystals, so as to improve catalytic performance. Active, good active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Preparation of linear Cu-Ni alloy nanocrystal catalyst for catalytic oxidation of organic waste gas

[0019] 1. Preparation of linear Cu-Ni alloy nanocrystals

[0020] Dissolve 0.1mmol copper acetylacetonate, 0.1mmol nickel acetylacetonate and 0.1mmol / L polyvinylpyrrolidone PVP in 15ml benzyl alcohol and stir for 10min, add 0.5ml aniline dropwise during the stirring process, and then perform ultrasonic treatment for 10min Allow the solution to mix well. After sonication, the mixed solution was transferred into a 25ml autoclave and maintained at 200°C for 12h. Naturally cooled to room temperature, the obtained product was washed with acetone and centrifuged for 8 min at a centrifugal speed of 10000 r / min, and then washed several times with a mixture of absolute ethanol and acetone. Finally, the product obtained by centrifugation was put into a freeze-drying box to dry.

[0021] 2. Prepare the supported catalyst and conduct the degradation test of organic was...

Embodiment 2

[0025] Example 2 Preparation of linear Cu-Ni alloy nanocrystals Catalytic reduction of methylene blue

[0026] 1. Preparation of linear Cu-Ni alloy nanocrystals

[0027] Dissolve 0.15mmol copper acetylacetonate, 0.075mmol nickel acetylacetonate and 0.2mmol / L polyvinylpyrrolidone PVP in 15ml benzyl alcohol and stir for 10min, add 1ml aniline dropwise during the stirring process, and then perform ultrasonic treatment for 10min The solution is mixed well. After sonication, the mixed solution was transferred into a 25ml autoclave and maintained at 175°C for 8h. Naturally cooled to room temperature, the obtained product was washed with acetone and centrifuged for 8 min at a centrifugal speed of 10000 r / min, and then washed several times with a mixture of absolute ethanol and acetone. Finally, the product obtained by centrifugation was put into a freeze-drying box to dry.

[0028] 2. Catalytic reduction of methylene blue test

[0029] Add 2ml NaBH to 100mL methylene blue 4 , an...

Embodiment 3

[0030] Example 3 Preparation of Linear Cu-Ni Alloy Nanocrystal Catalyst Catalyzing p-Nitrophenol

[0031] 1. Preparation of linear Cu-Ni alloy nanocrystals

[0032] Dissolve 0.225mmol copper acetylacetonate, 0.45mmol nickel acetylacetonate and 0.3mmol / L polyvinylpyrrolidone PVP in 15ml benzyl alcohol and stir for 10min, add 1.5ml aniline dropwise during the stirring process, and then perform ultrasonic treatment for 10min Allow the solution to mix well. After sonication, the mixed solution was transferred into a 25ml autoclave and maintained at 220°C for 16h. Naturally cooled to room temperature, the obtained product was washed with acetone and centrifuged for 8 min at a centrifugal speed of 10000 r / min, and then washed several times with a mixture of absolute ethanol and acetone. Finally, the product obtained by centrifugation was put into a freeze-drying box to dry.

[0033] 2. Catalytic hydrogenation reaction of p-nitrophenol

[0034]Weigh 2.0g of p-nitrophenol, 0.08g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com