Flame-retardant PVC cable insulation material or sheath material having electromagnetic shielding function, and preparation method thereof

An electromagnetic shielding and cable insulation technology, applied in the direction of organic insulators, insulators, plastic/resin/wax insulators, etc., can solve problems such as instrument and instrument interference, abnormal use, poor thermal stability, etc., to achieve low production costs and high production efficiency High, stable quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

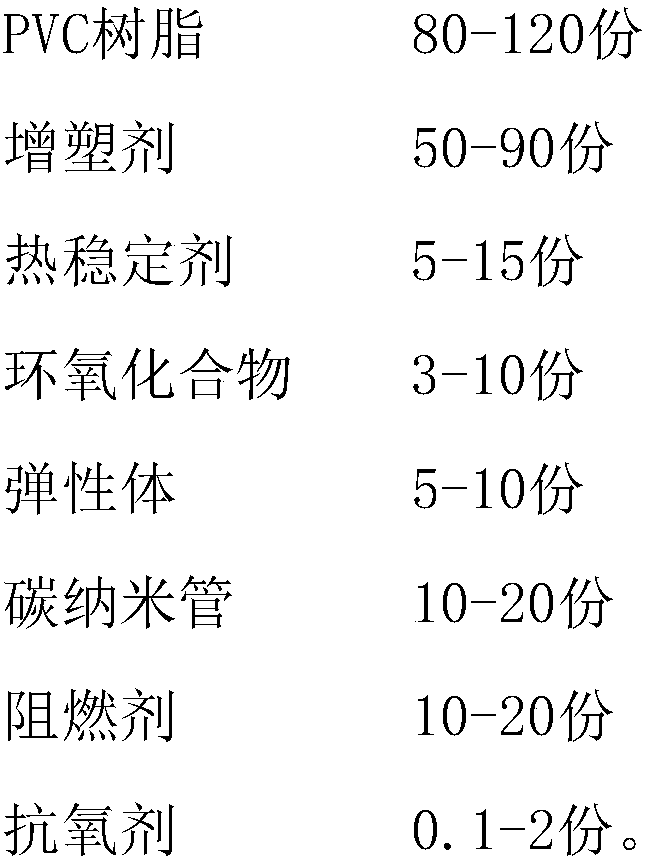

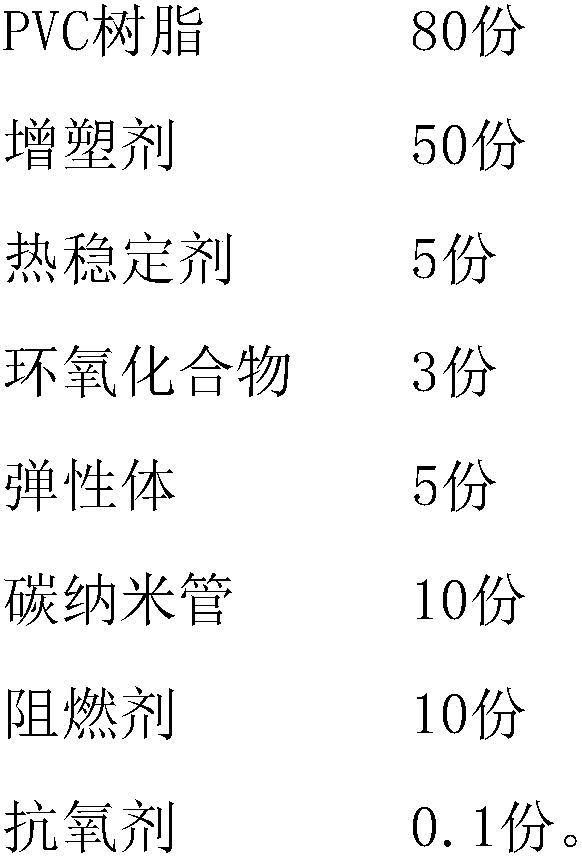

[0040] A flame-retardant PVC cable insulation material or sheath material with electromagnetic shielding function, comprising the following raw materials in parts by weight:

[0041]

[0042] The PVC resin is a PVC resin with an average degree of polymerization of 1000.

[0043] The plasticizer is trioctyl trimellitate.

[0044] The heat stabilizer is a calcium-zinc composite heat stabilizer.

[0045] The epoxy compound is epoxy soybean oil; the elastomer is thermoplastic polyurethane elastomer.

[0046] The carbon nanotubes are single-arm carbon nanotubes whose surfaces have been acidified.

[0047] The carbon nanotubes have a diameter of 10 nm and an aspect ratio of 100.

[0048] The flame retardant is triphenyl phosphate, o-diphenylisooctyl or diphenylisodecyl phosphate.

[0049] The antioxidant is tetrakis[methylene-3,5-(di-tert-butyl-4-hydroxy-phenyl)propionate]pentaerythritol ester.

[0050] It also includes 1 part of smoke suppressant; said smoke suppressant is ...

Embodiment 2

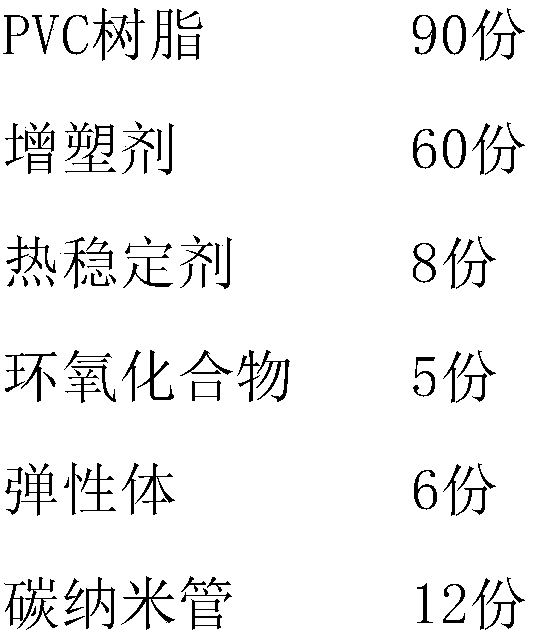

[0056] A flame-retardant PVC cable insulation material or sheath material with electromagnetic shielding function, comprising the following raw materials in parts by weight:

[0057]

[0058]

[0059] The PVC resin is a PVC resin with an average degree of polymerization of 1300.

[0060] The plasticizer is a mixture of trioctyl trimellitate and dioctyl phthalate.

[0061] The heat stabilizer is a calcium-zinc composite heat stabilizer.

[0062] The epoxy compound is epoxy tall oleate; the elastomer is powdered nitrile rubber.

[0063] The carbon nanotubes are multi-walled carbon nanotubes whose surfaces have been acidified.

[0064] The carbon nanotubes have a diameter of 20 nm and an aspect ratio of 200.

[0065] The flame retardant is chlorinated paraffin-52, chlorinated paraffin-70 or chlorinated paraffin-42.

[0066] The antioxidant is N,N'-bis[[3-(3,5)-di-tert-butyl-4-hydroxyphenyl]propionyl]hexamethylenediamine.

[0067] Also includes 3 parts of smoke suppress...

Embodiment 3

[0073] A flame-retardant PVC cable insulation material or sheath material with electromagnetic shielding function, comprising the following raw materials in parts by weight:

[0074]

[0075]

[0076] The PVC resin is a PVC resin with an average degree of polymerization of 1500.

[0077] The plasticizer is a mixture of trioctyl trimellitate and dioctyl terephthalate.

[0078] The heat stabilizer is a calcium-zinc composite heat stabilizer.

[0079] The epoxy compound is epoxy tetrahydrophthalate di(2-ethylhexyl) ester; the elastomer is acrylic elastomer.

[0080] The carbon nanotubes are single-arm carbon nanotubes whose surfaces have been acidified.

[0081] The carbon nanotubes have a diameter of 50 nm and an aspect ratio of 500.

[0082] The flame retardant is bis(hexachlorocyclopentadiene) cyclooctane or antimony trioxide.

[0083] The antioxidant is tris[2,4-di-tert-butylphenyl]phosphite.

[0084] Also includes 5 parts of smoke suppressant; said smoke suppressa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap