Method for preparing nickel modified hexagonal BN and sealing material of nickel modified hexagonal BN in chemical plating solution

An electroless nickel plating and electroless plating technology, which is applied in the field of preparing nickel-modified hexagonal BN and its sealing materials, can solve the problems of fast nickel particle deposition and easy agglomeration, so as to reduce agglomeration, improve wetting performance and stability Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

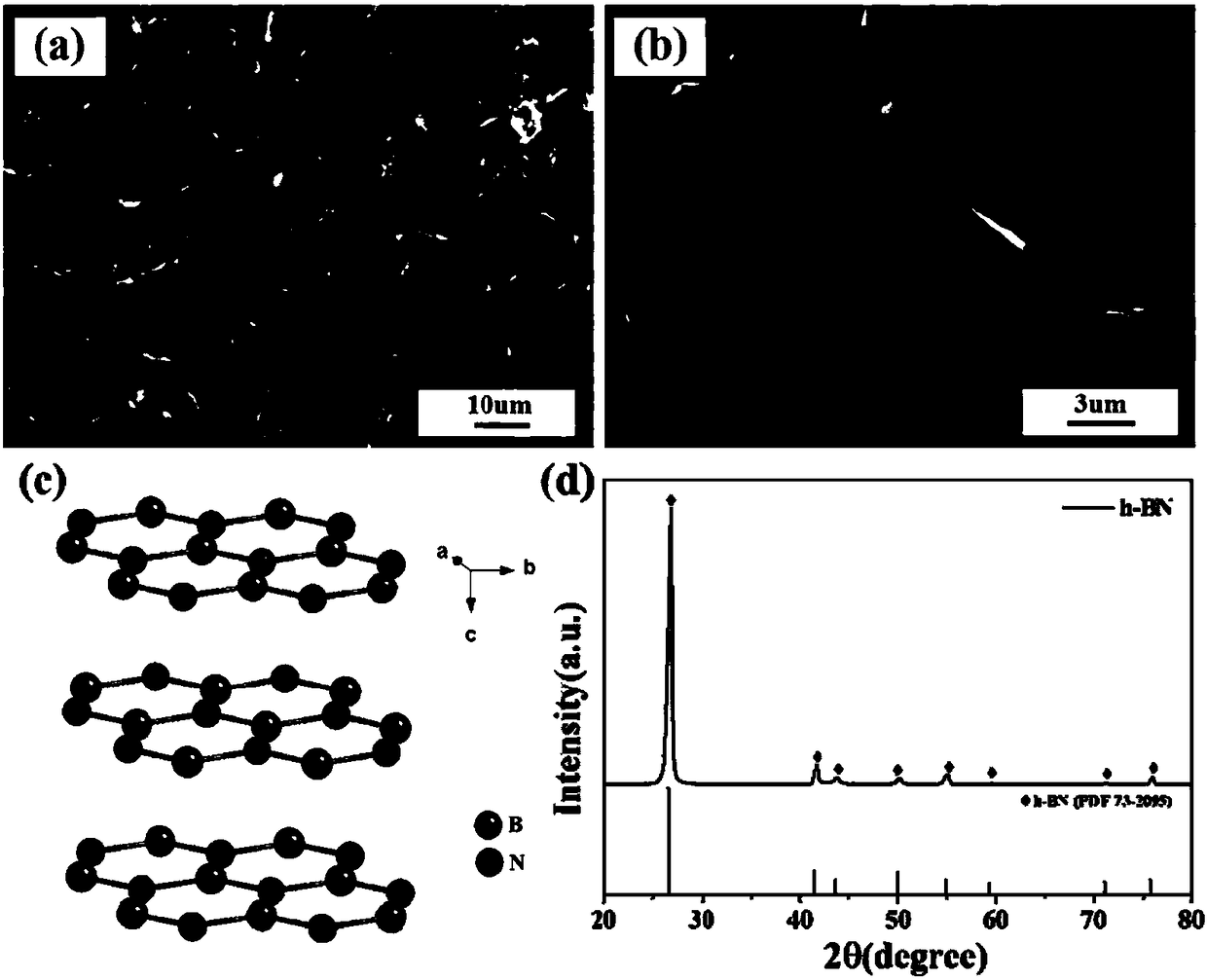

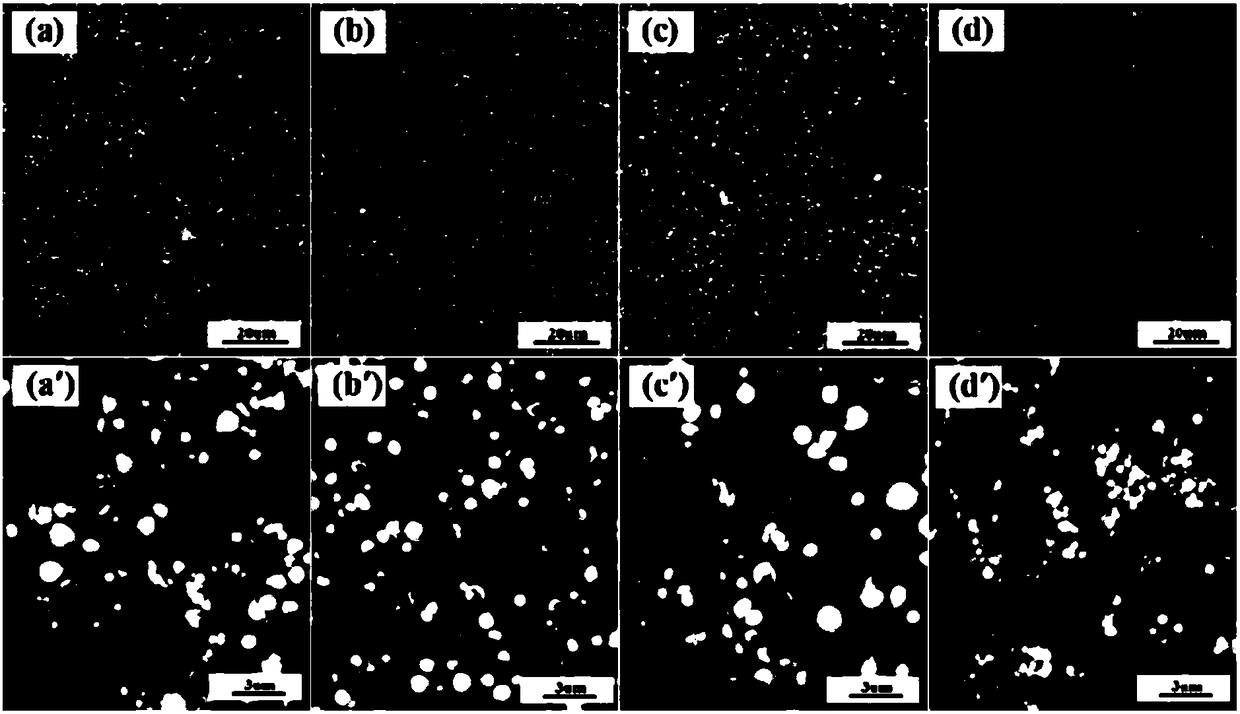

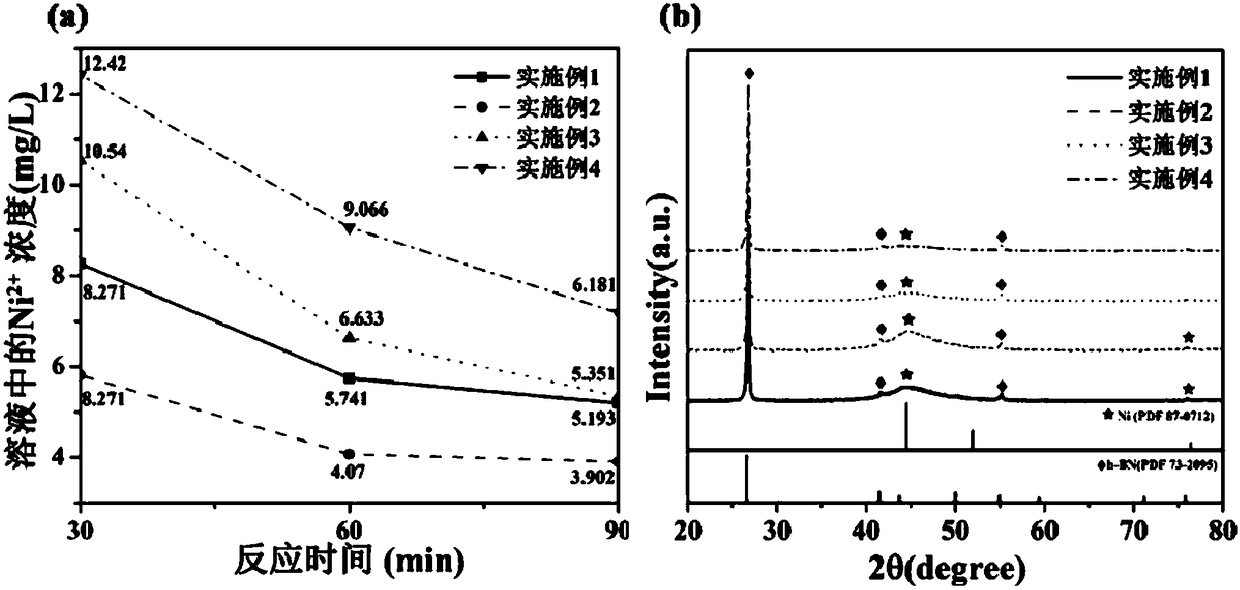

[0043] The method for preparing uniformly dispersed nickel-modified hexagonal BN in an electroless plating solution and further preparing a sealing material, the specific steps are as follows:

[0044] (1) Weigh 30 g of hexagonal BN, ultrasonically clean it with 100 mL of ethanol for 10 min, filter, then filter it, add 50 mL of deionized water, centrifuge and dry to obtain hexagonal BN particles with clean surfaces.

[0045] (2) take each raw material by 40g / L nickel sulfate (volume here refers to the final volume of electroless nickel plating solution), 30g / L sodium citrate, 25g / L sodium hypophosphite, 20g / L boric acid, and Dissolve each raw material with a small amount of deionized water respectively, then add the nickel sulfate solution into the sodium citrate solution, mix well, then add sodium hypophosphite solution and boric acid solution to the mixed solution in turn to obtain an electroless nickel plating solution , Adjust the pH of the electroless nickel plating solut...

Embodiment 2

[0050] The method for preparing uniformly dispersed nickel-modified hexagonal BN in an electroless plating solution and further preparing a sealing material, the specific steps are as follows:

[0051] (1) Weigh 60 g of hexagonal BN, wash it with 250 mL of ultrasonic ethanol for 30 min, then filter it, add 80 mL of deionized water, and centrifuge and dry to obtain hexagonal BN particles with clean surfaces.

[0052] (2) Weigh each raw material by 50g / L nickel sulfate, 40g / L sodium citrate, 33g / L sodium hypophosphite, 25g / L boric acid, and dissolve each raw material with a small amount of deionized water respectively, and then nickel sulfate The solution is added in the sodium citrate solution, after mixing, the sodium hypophosphite solution and the boric acid solution are added successively to the mixed solution to obtain an electroless nickel plating solution, and the pH of the electroless nickel plating solution is adjusted to be 9 with aqueous sodium hydroxide solution. The...

Embodiment 3

[0057] The method for preparing uniformly dispersed nickel-modified hexagonal BN in an electroless plating solution and further preparing a sealing material, the specific steps are as follows:

[0058] (1) Weigh 40 g of hexagonal BN, ultrasonically clean it with 150 mL of ethanol for 20 min, then filter it, add 60 mL of deionized water, and centrifuge and dry to obtain hexagonal BN particles with clean surfaces.

[0059] (2) Weigh each raw material according to 55g / L nickel sulfate, 35g / L sodium citrate, 40g / L sodium hypophosphite, and 30g / L boric acid, and dissolve them with a small amount of deionized water respectively, then add the nickel sulfate solution into the sodium citrate solution, and after mixing, add sodium hypophosphite solution and boric acid solution to the mixed solution in turn to obtain an electroless nickel plating solution, adjust the pH of the electroless nickel plating solution to 9.5 with ammonia monohydrate, and then add chlorine Fe-1-butyl-3-methylim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com