Preparation method of nano-silicon composite negative electrode material for lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, nanotechnology for materials and surface science, negative electrodes, etc., can solve the problems of conductive network collapse, aggravated silicon corrosion and capacity attenuation, difficult surface analysis of lithium, etc. , to achieve the effects of alleviating the effect of volume expansion and contraction, high initial charge and discharge efficiency, environmental friendliness and pollution-free

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

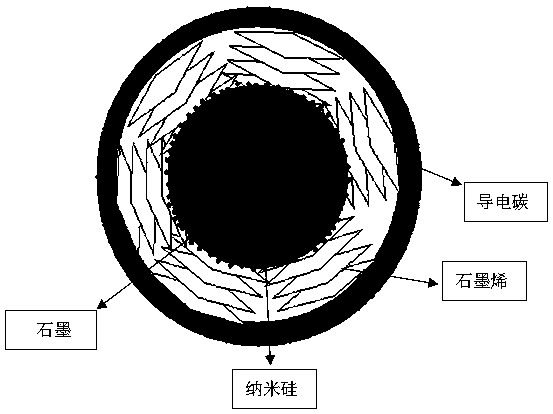

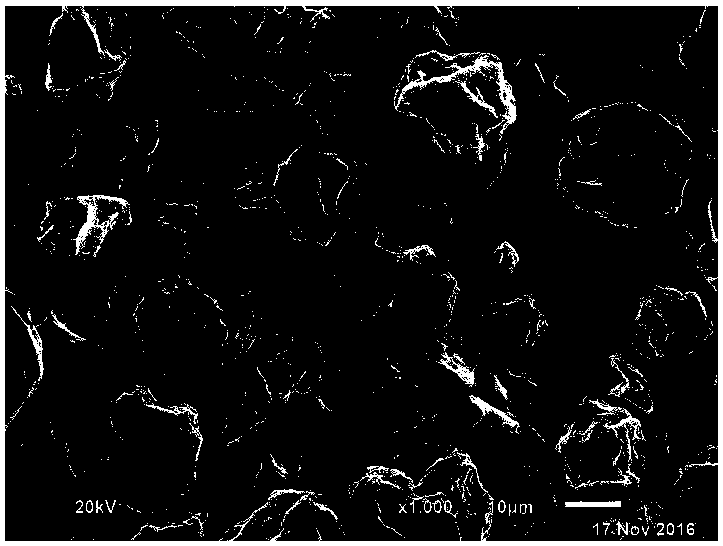

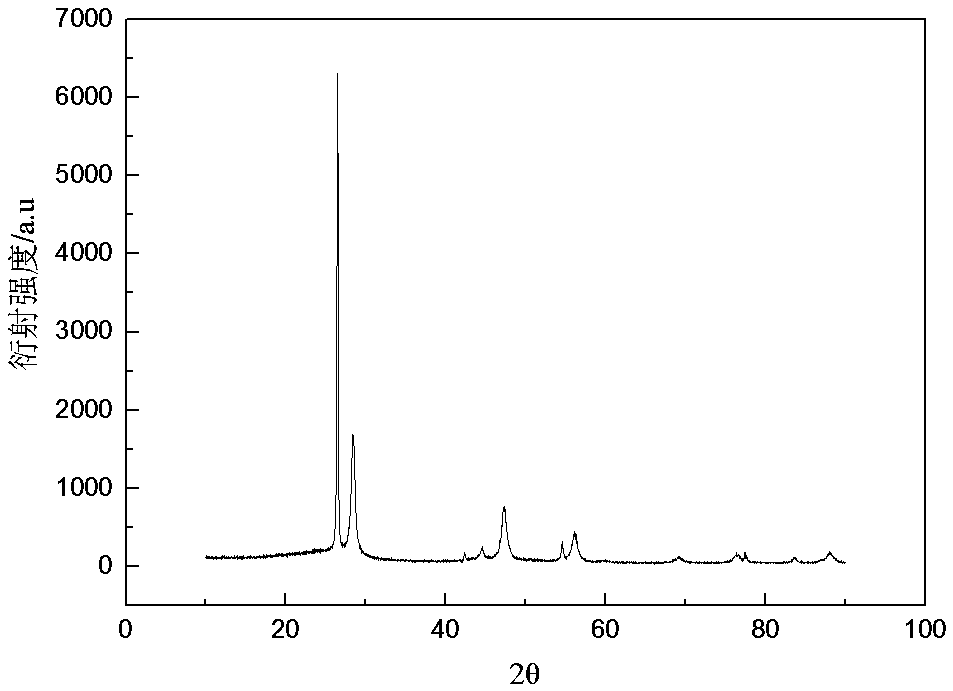

[0032] A preparation method of nano-silicon composite negative electrode material for lithium ion battery, comprising the steps of:

[0033] A1. Add aminopropyltrimethoxysilane to a flask of nano-silica powder with a medium particle size of 100nm dispersed in an ethanol solvent and mix it. The mixing mass ratio is 1:20, and then put it into an ultrasonic cleaner for 4 hours of ultrasonication. The frequency is adjusted to 40kHZ, and the modified nano-silicon slurry is obtained.

[0034] A2. Add artificial graphite powder with a medium particle size of 10 μm to the modified nano-silicon slurry and mix it with a mixing mass ratio of 1:1. After mixing, put it into a planetary ball mill in a 5L stainless steel tank, and feed it with argon protective gas. High-energy ball milling under the condition of 200r / min for 10h, and then spray-dried to obtain a nano-silicon / graphite precursor.

[0035] A3. Stir and disperse the nano-silicon / graphite in an ethanol solvent for 1 h, add graph...

Embodiment 2

[0039] A preparation method of nano-silicon composite negative electrode material for lithium ion battery, comprising the steps of:

[0040] A1, add the silane coupling agent to the nano-silica powder flask with a medium particle size of 100nm dispersed in an ethanol solvent and mix it. The mixing mass ratio is 1:15, and then put it into an ultrasonic cleaner for ultrasonication for 6h. The ultrasonic frequency is adjusted to 40kHZ, the modified nano-silicon slurry is obtained.

[0041] A2. Add artificial graphite powder with a medium particle size of 10 μm to the modified nano-silicon slurry and mix it with a mixing mass ratio of 2:1. After mixing, put it into a planetary ball mill in a 5L stainless steel tank, and feed it with argon protective gas. High-energy ball milling at 200 r / min for 20 hours, and then spray drying to obtain nano-silicon / graphite.

[0042] A3. Stir and disperse the nano-silicon / graphite in an ethanol solvent for 1 h, add graphene oxide with 100 layers i...

Embodiment 3

[0045] A preparation method of nano-silicon composite negative electrode material for lithium ion battery, comprising the steps of:

[0046] A1. Add the silane coupling agent to the nano-silica powder flask with a medium particle size of 200nm dispersed in the ethylene-propanol solvent and mix it. The mixing mass ratio is 1:20, and then put it into an ultrasonic cleaner for 8h ultrasonic cleaning. Adjust to 40kHZ to obtain the modified nano-silicon slurry.

[0047] A2. Add artificial graphite powder with a medium particle size of 15 μm to the modified nano-silicon slurry and mix it with a mixing mass ratio of 3:1. After mixing, put it into a planetary ball mill in a 5L stainless steel tank, and feed it with argon protective gas. High-energy ball milling at 500 r / min for 10 h, and then spray drying to obtain nano silicon / graphite.

[0048] A3. Stir and disperse the nano-silicon / graphite in an ethanol solvent for 3 hours, add graphene oxide with 200 layers into the nano-silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com