A kind of synthetic method of high-quality zinc pyrithione

A technology of zinc pyrithione and its synthesis method, which is applied in the chemical industry and can solve problems such as unfavorable industrial production, loss of raw materials, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

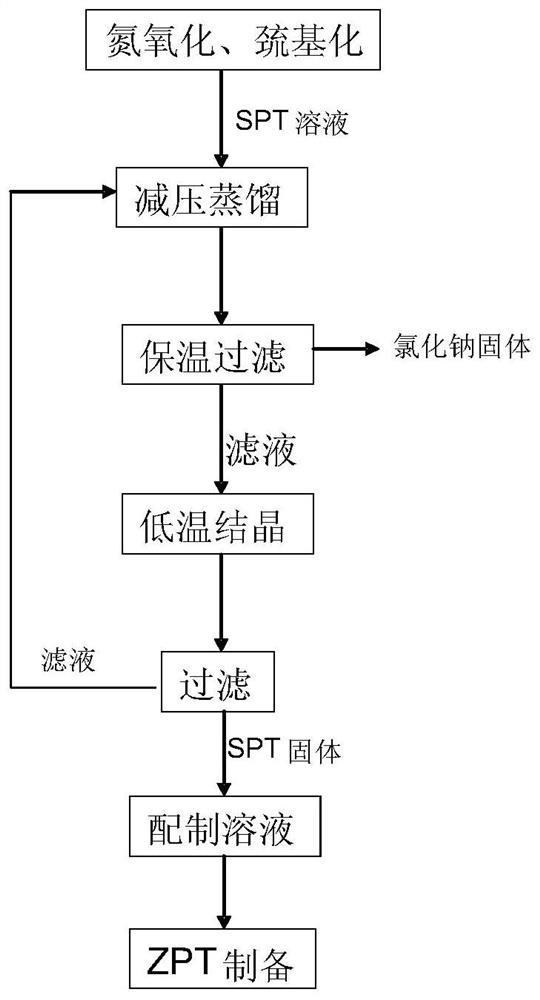

Method used

Image

Examples

Embodiment 1

[0028] Add 100g of 2-chloropyridine, 100g of distilled water and 3.0g of TS-1 molecular sieve catalyst into a 500mL four-necked flask, start stirring and heat up to 65°C, then start to drop 100g of hydrogen peroxide with a mass fraction of 30%, and control the dropping rate to maintain the reaction The temperature of the solution is 70-80°C. After the dropwise addition, the temperature is kept for 2 hours, and the temperature of the reaction solution is lowered to 45°C, and filtered to obtain a solution of 2-chloropyridine nitrogen oxide. Add 118g of sodium hydrosulfide with a mass fraction of 43% and 121g of a mass fraction of 30% sodium hydroxide solution into a 1000mL four-necked flask, start stirring and heat up to 65°C, and start to drop the 2-chloropyridine nitrogen oxide prepared above Solution, control the reaction temperature at 70-80°C, keep it warm for 2 hours after the dropwise addition, cool the reaction solution to 45°C, add 31% hydrochloric acid dropwise to adjus...

Embodiment 2

[0032]Add 100g of 2-chloropyridine, 100g of distilled water and 3.0g of TS-1 molecular sieve catalyst into a 500mL four-necked flask, start stirring and heat up to 65°C, then start to drop 100g of hydrogen peroxide with a mass fraction of 30%, and control the dropping rate to maintain the reaction The temperature of the solution is 70-80°C. After the dropwise addition, the temperature is kept for 2 hours, and the temperature of the reaction solution is lowered to 45°C, and filtered to obtain a solution of 2-chloropyridine nitrogen oxide. Add 118g of sodium hydrosulfide with a mass fraction of 43% and 121g of a mass fraction of 30% sodium hydroxide solution into a 1000mL four-neck flask, start stirring and when the temperature rises to 65°C, start to dropwise add the 2-chloropyridine nitrogen oxide prepared above solution, control the reaction temperature at 70-80°C, keep the reaction for 2 hours after the dropwise addition, cool the reaction solution to 45°C, add 31% hydrochlor...

Embodiment 3

[0036] The remaining 183.5g of pyrithione sodium solution (mass fraction of pyrithione sodium 33.9%) in implementation 1 continued to be distilled under reduced pressure at a temperature of 90°C, and when 35g of water was steamed, stop the rotary steaming and filter at 90°C Obtain 5.6g of sodium chloride solid and 142.9g of sodium pyrithione filtrate with a mass fraction of 43.1%. The sodium pyrithione filtrate is cooled to -2°C and stirred. After white crystals are precipitated, continue to insulate and stir for 30 minutes, and then filter to obtain pyrithione 44 g of sodium crystals (sodium pyrithione content: 76.4%) and 98.9 g of sodium pyrithione filtrate. Then 44g of sodium pyrithione crystals were dissolved in 292.2g of distilled water to prepare a 10% sodium pyrithione solution with a pH value of 9.1, stirred and heated to 50°C, and 142g of a mass fraction of 25% was added dropwise After the zinc sulfate solution was added dropwise, the solution was incubated and stirre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com