Method for extracting microplastics in dewatered sludge and lab-scale test device

A dewatered sludge and extraction method technology, which is applied in the direction of measuring devices, plastic recycling, and analysis materials, can solve the problems of secondary environmental pollution, high cost, and inapplicable extraction of microplastic particles in the dewatered sludge system, achieving recycling The effect of high efficiency, low cost, and small sample demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

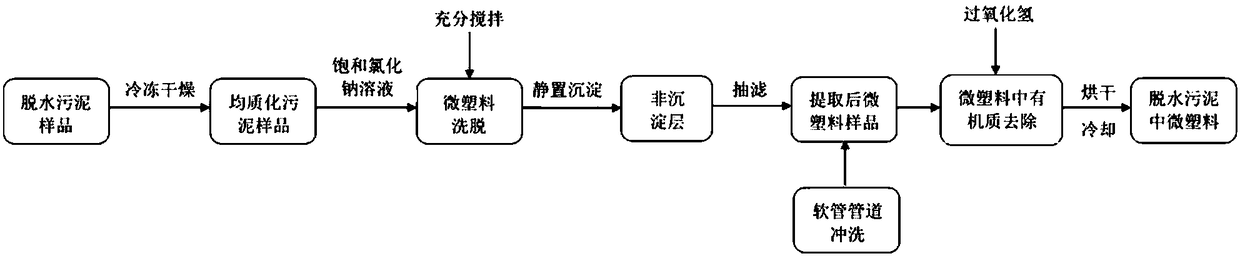

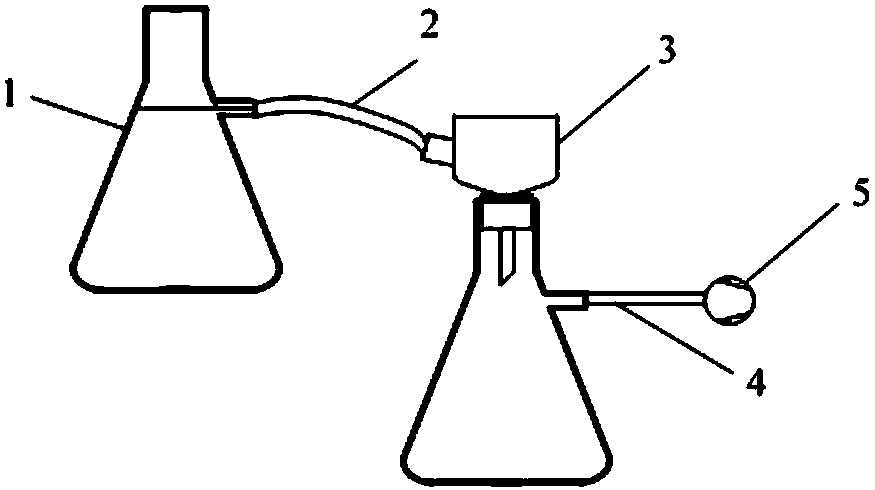

[0029] In this example, see Figure 1~4 , sampling dewatered sludge samples from 10 sewage plants, using the method of extracting microplastics in dewatered sludge, including the following steps:

[0030] a. Freeze-dry and homogenize the dewatered sludge sample from a sewage plant to obtain raw materials to be treated. The freeze-drying temperature is -20°C, and the freeze-drying time is 24 hours;

[0031] b. Mining density is 1.2g / cm 3 The sodium chloride solution is used as a density solution for subsequent use, get 20g of the raw material to be treated obtained in the step a in the suction filter bottle, add the sodium chloride solution to the suction filter bottle, and mix the raw material to be treated with the sodium chloride solution Form a mixed solution, and use a magnetic stirrer to control the stirring rate to 400r / min to fully stir the suspension for 1 hour until the solution is completely suspended to obtain a mixed suspension;

[0032] c. Stand still the suspen...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, especially in that:

[0045] In this embodiment, a method for extracting microplastics from dewatered sludge includes the following steps:

[0046] a. This step is the same as in Embodiment 1;

[0047] B. adopt saturated sodium chloride solution as the density solution for subsequent use, get 10g of the raw material to be treated obtained in said step a in the suction filter bottle, add saturated sodium chloride solution to the suction filter bottle, make the raw material to be treated and saturated Mix the sodium chloride solution to form a mixed solution, and use a magnetic stirrer to control the stirring rate to 400r / min to fully stir the suspension for 1h until the solution is completely suspended to obtain a uniform suspension;

[0048] c. Stand still the suspension prepared in the step b, and control the standing time so that the suspension is completely stratified into a sedimentation layer and a non-sedimen...

Embodiment 3

[0055] This embodiment is basically the same as the previous embodiment, and the special features are:

[0056] In this example, commercial plastic polyethylene of 30 mesh and 200 mesh, polypropylene of 20 mesh and 200 mesh, polystyrene of 40 mesh and 200 mesh were purchased, as microplastic samples, and according to this embodiment—using microplastics in dewatered sludge The extraction method of plastics is tested for the recovery rate of microplastic particles. The sludge after extracting clean microplastic particles was taken as the experimental medium, and the microplastic sample was mixed with the sludge after clean microplastic particles as the sludge experiment material in the experiment of this embodiment, and the simulation experiment was carried out. Each size of commercial plastic Three parallel experiments were carried out, and the recovery rate was 66.7-97.8%, as shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com