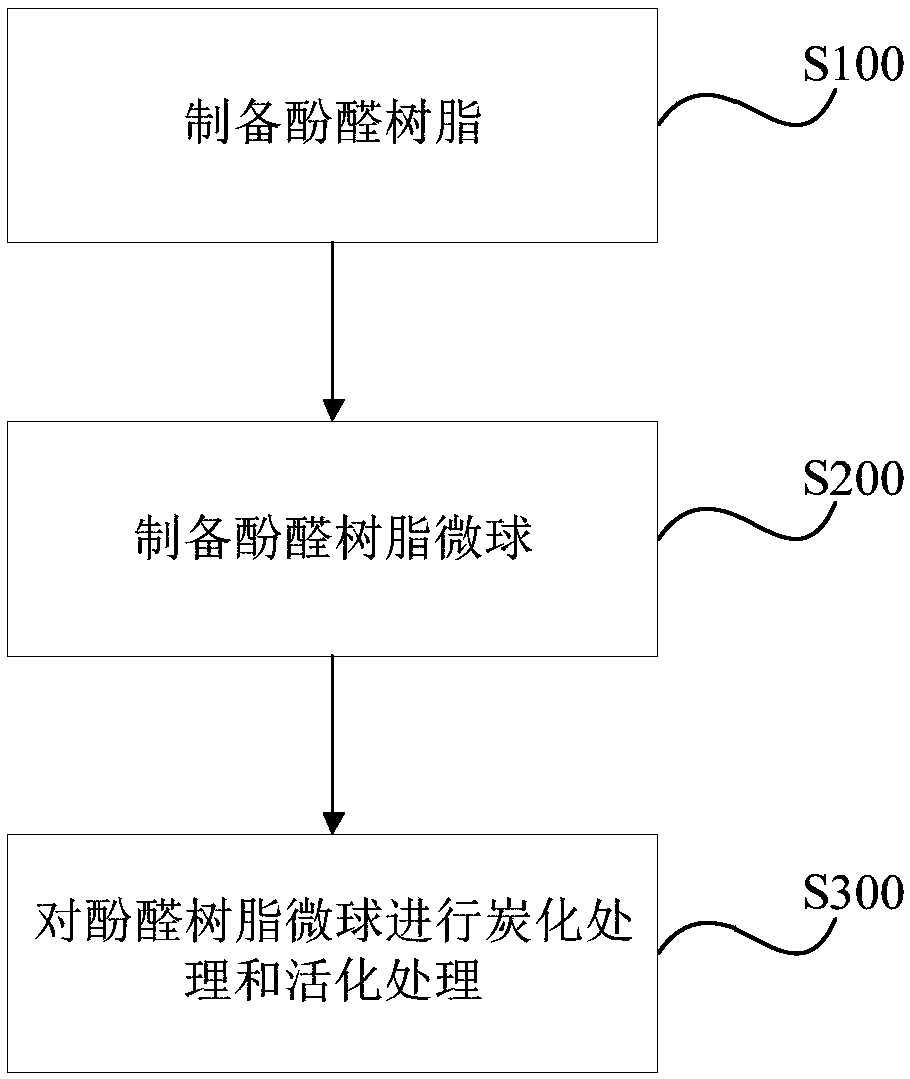

Phenolic resin based active carbon as well as preparation method and application thereof

A technology of phenolic resin and activated carbon, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of activated carbon pore blockage, unsatisfactory effect, and low silver adhesion, achieve good mechanical strength, and avoid secondary Pollution, not easy to fall off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

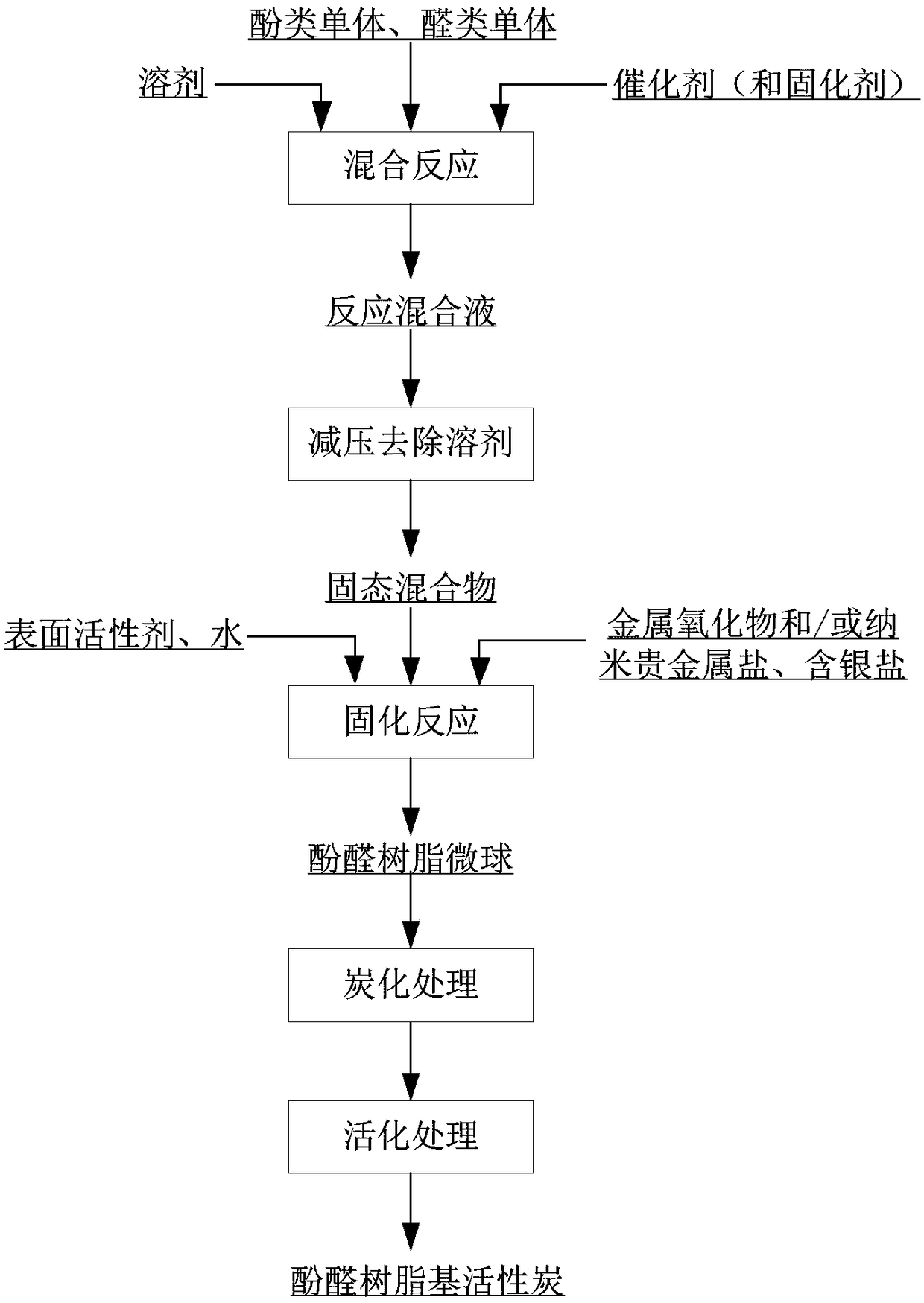

[0092] Prepare the phenolic resin-based activated carbon (the total mass of metal oxide and nano-silver accounts for 6.0% by weight of described activated carbon) that is loaded with metal oxide and nano-silver, and concrete preparation method is as follows:

[0093] (1) phenolic monomers, aldehyde monomers, curing agent, catalyst and solvent are mixed to obtain a reaction mixture, wherein the phenols are phenol, the aldehydes are formaldehyde, and the curing agent is hexamethylenetetramine, The solvent is methanol, and the molar ratio of phenol and formaldehyde is 1:1.2; hexamethylenetetramine is 1.5% of the mass of phenol and the mass of methanol is 5 times that of phenol.

[0094] (2) remove the solvent in the reaction mixture under reduced pressure, so as to obtain the solid mixture containing phenolic resin;

[0095] (3) Mix the solid mixture with metal oxide, silver-containing salt, surfactant and water, and slowly heat up under constant stirring to obtain phenolic resin...

Embodiment 2

[0099] Preparation is loaded with the phenolic resin-based activated carbon of nano-noble metal and nano-silver (the total mass of nano-noble metal and nano-silver accounts for 7.0% by weight of the activated carbon),

[0100] The difference between the specific preparation method and Example 1 is that in step (3), the solid mixture is mixed with nano-precious metal salt, silver-containing salt, surfactant and water, and the temperature is slowly raised under constant stirring, so as to obtain phenolic resin microspheres, wherein, The nano-noble metal salt is ruthenium nitrate, the silver-containing salt is silver nitrate, and the mass ratio of the solid mixture to the nano-noble metal salt, silver-containing salt, surfactant and water is 100:8:1.5:2.5:1000.

Embodiment 3

[0102] Prepare the phenolic resin-based activated carbon (the total mass of metal oxide, nano-noble metal and nano-silver accounts for 7.5% by weight of the activated carbon) loaded with metal oxide, nano-noble metal and nano-silver,

[0103] The specific preparation method differs from Example 1 in that in step (3), the solid mixture is mixed with metal oxides, nano-precious metal salts, silver-containing salts, surfactants and water, and the temperature is slowly raised under uniform stirring, so as to obtain phenolic resin microparticles. ball, wherein the metal oxide is manganese dioxide, the nano-noble metal salt is ruthenium nitrate and palladium nitrate, the silver-containing salt is silver nitrate, and the solid mixture is mixed with metal oxide, nano-noble metal salt, silver-containing salt, surfactant and water. The mass ratio is 100:5:3:1:2.5:800.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com