Method for co-producing gelatinous and emulsified pectin by using chicory/taro meal

A gel type and emulsification type technology, applied in the field of food processing, can solve the problems of high degree of acetylation, poor structural uniformity and low degree of acetylation of chicory/taro pectin, and achieve good purity and uniformity, outstanding performance, The effect of low degree of acetylation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

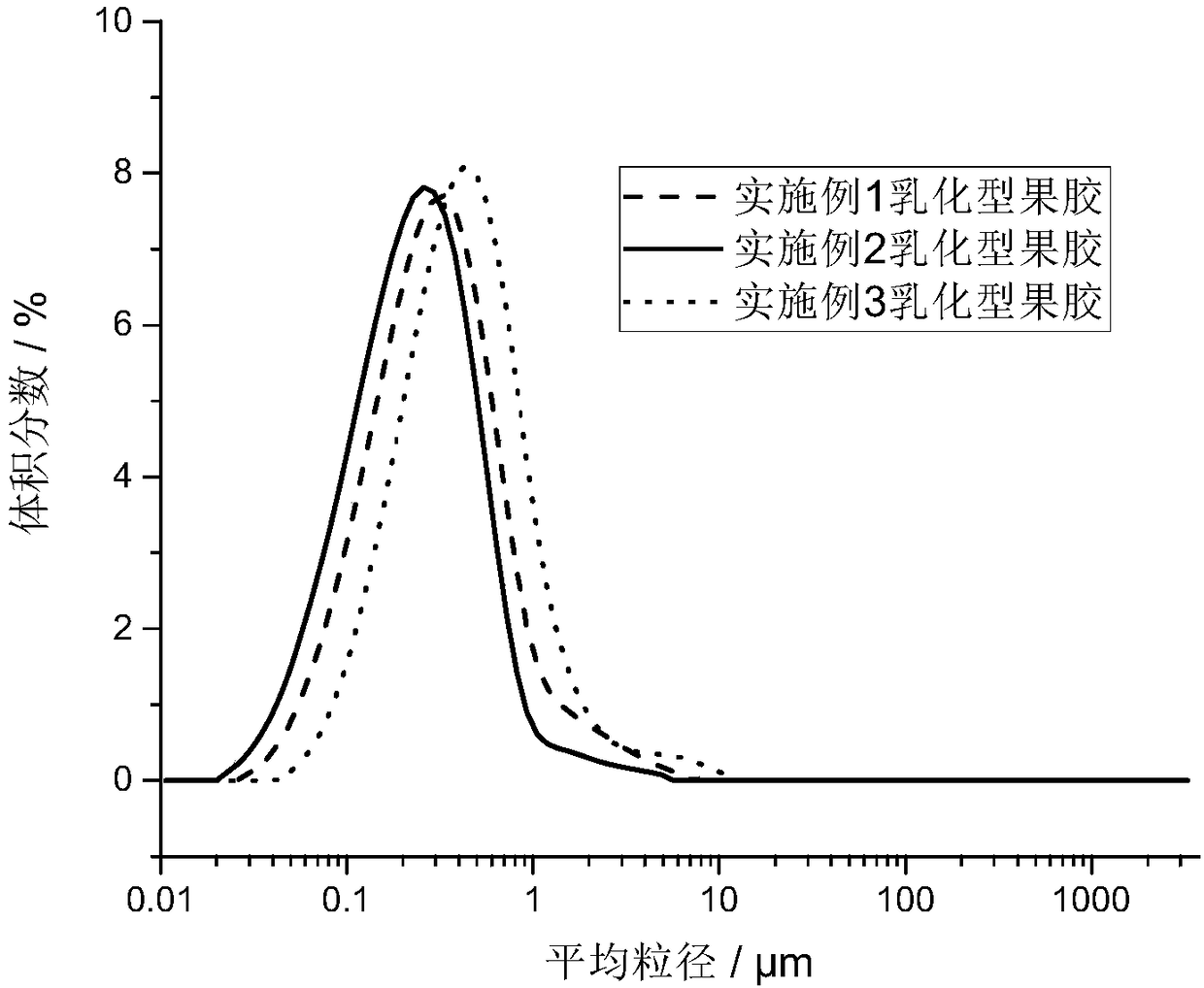

Embodiment 1

[0057] (1) Raw material pretreatment: wash fresh chicory, shred it and soak it in pure water at 80°C for 1 hour, separate the residue and liquid, use the filtrate to extract inulin and fructooligosaccharides, rinse the filter residue with clean water until the water is clear, filter Dry, remove sugar and other impurities, and dry to obtain chicory meal. The main components of the obtained dry-based chicory meal are: 21% cellulose, 23% hemicellulose; 1% lignin; 27% pectin, 8% protein, The ash content is 0.35%; the chicory meal is pulverized into fine particles, passed through a 20-mesh sieve for later use;

[0058] (2) Preparation of gel-type pectin:

[0059] 2a. Chelating agent soaking: Mix 15kg of pretreated chicory meal with 300L ammonium oxalate solution (0.5g / L), the ratio of solid to liquid is 1:20kg / L, the soaking temperature is 80°C, the extraction pH is 5.8, and the soaking time is 2h, air flow stirring, speed 120rpm;

Embodiment 2

[0092] (1) Raw material pretreatment: Wash and shred fresh Jerusalem artichoke, soak in pure water at 80°C for 1 hour, use a plate and frame filter to separate the residue from the liquid, rinse the filter residue with clean water until the water is clear, and remove sugar and other impurities , filtered and dried to obtain Jerusalem artichoke meal, the main components of the dry base Jerusalem artichoke meal are: 23% cellulose, 23% hemicellulose; 0.9% lignin; 29% pectin, 6% protein, and 0.45% ash; Crush the chicory meal into fine particles and pass through a 20-mesh sieve for later use; crush the Jerusalem artichoke meal and pass through a 60-mesh sieve for later use;

[0093] (2) Preparation of gel-type pectin:

[0094] 2a. Chelating agent soaking: mix 20kg of chicory meal with 600L sodium hexametaphosphate solution (mass concentration 0.35%), the ratio of solid to liquid is 1:30w / v (g / L), the soaking temperature is 90°C, and the extraction pH is 5.5 , the soaking time is 1...

Embodiment 3

[0112] (1) Raw material pretreatment: wash fresh chicory, shred it and soak it in pure water at 80°C for 1.5 hours, separate the filter residue through a three-legged centrifuge (2000rpm, 20min), rinse the filter residue with clean water until the water is clear, remove Sugar and other impurities are filtered and dried to obtain chicory meal. The main components of the obtained dry-based chicory meal are: 22% cellulose, 24% hemicellulose; 1.2% lignin; 26.7% pectin, 9% protein, and ash 0.33%; crush the chicory meal into fine particles, pass through a 20-mesh sieve for later use; crush the chicory meal, pass through a 20-mesh sieve for later use;

[0113] (2) Preparation of gel-type pectin:

[0114] 2a. Chelating agent soaking: Mix 18kg of pretreated chicory meal with 500L of ammonium oxalate solution (0.4g / L), the ratio of solid to liquid is 1:25w / v, the soaking temperature is 82°C, the extraction pH is 5.6, and the soaking time is 2.5h, mechanical stirring speed 250rpm;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com