Compound microorganism liquid fertilizer

A technology of compound microorganism and liquid fertilizer, applied in the field of compound microorganism liquid fertilizer, can solve the problems of shortening the shelf life of liquid fertilizer, single effective nutrients of fertilizer, affecting the survival of viable bacteria, etc., so as to improve the disease resistance of crops, reduce the amount of chemical fertilizer, reduce The effect of pesticide dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

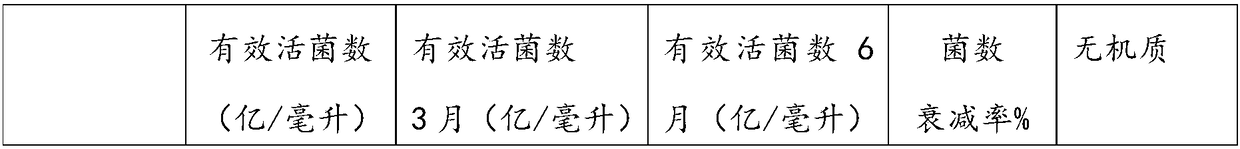

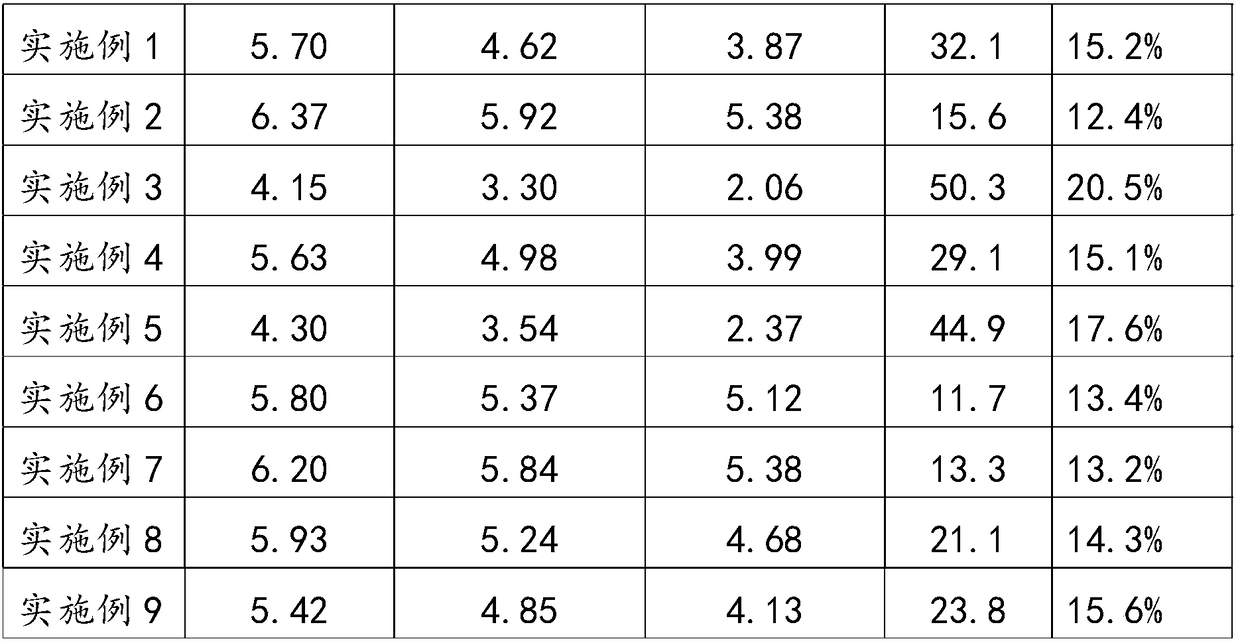

Examples

preparation example Construction

[0024] The preparation method of the microbial bacterial liquid comprises the steps of: adding the medium into the first tank and the second tank respectively, sealing them, and sterilizing them; 0.07-0.14Mpa; when the temperature drops to 28-36°C, inoculate the first tank at constant temperature and pressure; ferment for 9-12 hours, add the fermentation liquid of the first tank to the second tank to continue fermentation, the control conditions are the same as the first tank One can, when 90% to 95% of the bacterial cells are formed, the can is put into the can to obtain the microbial bacterial liquid. Wherein, the first tank is a fermented seed tank, and the second tank is a fermenter; the inoculated bacteria are selected from any one or more of Bacillus subtilis, Bacillus licheniformis, Bacillus megaterium, Bacillus colloidis and Bacillus cereus. The number of calcium in the microbial liquid fertilizer is 1-3 parts, and the number of magnesium-containing parts is 1-3 parts....

Embodiment 1

[0029] Add 300 and 3000L water into the fermented seed tank and fermenter respectively, and then add the Bacillus subtilis culture medium (add 20g glucose, 15g peptone, 5g sodium chloride, 0.5g beef extract to 1L water) into the fermented seed tank and fermenter respectively middle. Close the fermented seed tank and fermenter, turn on the stirring paddle, sterilize with steam under constant stirring, keep the temperature at 121°C for 30 minutes, and thoroughly sterilize pipe fittings such as valves at the same time; Cooling treatment, during the cooling process, the purified compressed air is continuously fed into the fermented seed tank and fermentation tank to ensure that the tank pressure is 0.07-0.14Mpa. When the temperature drops to 28-36°C, take the Bacillus subtilis seeds to the fermentation workshop, inoculate the fermented seed tank with an inoculation amount of 1:10, and ferment after inoculation. The temperature is controlled at 28-36°C, and the tank pressure is con...

Embodiment 2

[0033] Prepare microbial bacterium liquid by the method of embodiment 1;

[0034] 12 parts of Bacillus subtilis bacteria liquid, 14 parts of urea, 10 parts of potassium nitrate, 10 parts of amino acid, 4 parts of EDTA-Ca, 2 parts of magnesium nitrate, 18 parts of molasses liquid.

[0035] Carry out mixing, stirring, canning by the same method in embodiment 1.

[0036] In this embodiment, the number of viable bacteria in the fermented liquid before mixing and stirring was detected to be 680 million / ml. After adding the above-mentioned various substances and mixing and stirring for canning, the number of viable bacteria was sampled and detected to be 587 million / ml. After 6 days, the number of viable bacteria was detected to be 637 million / ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com