A kind of micro polyacrylamide hydrogel based on graphene/cellulose base and preparation method thereof

A technology of cellulose hydrogel and polyacrylamide, which is applied in the field of textile materials, can solve the problems of low open circuit voltage and difficulty in meeting the needs of use, and meet the needs of use, good biocompatibility and mechanical flexibility, and a preparation method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

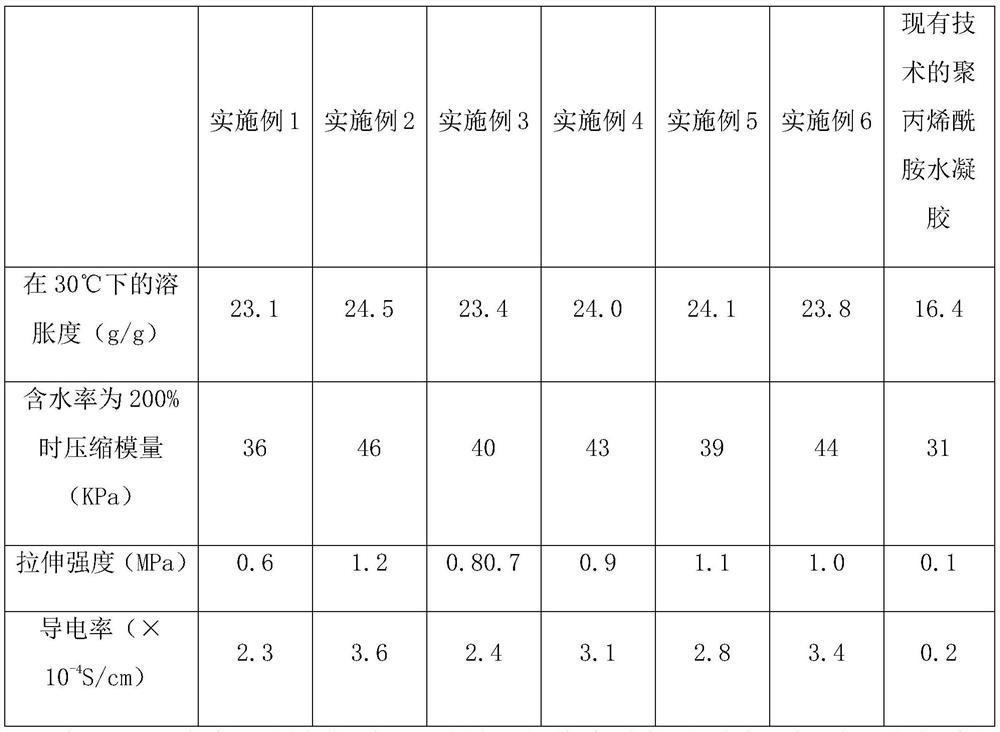

Examples

Embodiment 1

[0026] (1) According to the mass ratio of microcrystalline cellulose, graphene, N,N-methylene bisacrylamide and benzoyl peroxide is 10:1:7:1, the microcrystalline cellulose solution of 1.5wt% Add graphene, mix well, add crosslinking agent N,N-methylenebisacrylamide, mix well, add initiator benzoyl peroxide, stir at 500r / min at 80°C Polymerize for 24 hours to obtain graphene-coated cellulose hydrogel particles.

[0027] (2) According to acrylamide, graphene-coated cellulose hydrogel particles, N,N-methylenebisacrylamide, N,N,N',N'-tetramethylethylenediamine and ammonium persulfate The material ratio is 7:1:0.1:0.4:0.7, add graphene-coated cellulose hydrogel particles to the acrylamide solution, mix well, add the crosslinking agent N,N-methylenebisacrylamide Mix with the catalyst N,N,N',N'-tetramethylethylenediamine, add the initiator ammonium persulfate, and stir and polymerize at 30°C for 12 hours to obtain a graphene / cellulose / polyacrylamide composite Hydrogels.

[0028] (...

Embodiment 2

[0032] (1) According to the mass ratio of microcrystalline cellulose, graphene, N,N-methylenebisacrylamide and benzoyl peroxide is 10:2:8:1.5, the microcrystalline cellulose solution of 5.5wt% Add graphene, mix well, add crosslinking agent N,N-methylenebisacrylamide, mix well, add initiator benzoyl peroxide, stir at 800r / min at 90°C Polymerize for 30 hours to obtain graphene-coated cellulose hydrogel particles.

[0033] (2) According to acrylamide, graphene-coated cellulose hydrogel particles, N,N-methylenebisacrylamide, N,N,N',N'-tetramethylethylenediamine and ammonium persulfate The material ratio is 10:2:0.2:0.5:0.8, add graphene-coated cellulose hydrogel particles to the acrylamide solution, mix well, add the crosslinking agent N,N-methylenebisacrylamide Mix with the catalyst N,N,N',N'-tetramethylethylenediamine, add the initiator ammonium persulfate, and stir and polymerize at 40°C for 24 hours to obtain a graphene / cellulose / polyacrylamide composite Hydrogels.

[0034]...

Embodiment 3

[0038] (1) According to the mass ratio of microcrystalline cellulose, graphene, N,N-methylenebisacrylamide and benzoyl peroxide, it is 10:1.5:7.2:1.3, in the 3wt% microcrystalline cellulose solution Add graphene, mix well, add cross-linking agent N,N-methylenebisacrylamide, mix well, add initiator benzoyl peroxide, stir and polymerize at 85°C at a rate of 600r / min After 26 hours, graphene-coated cellulose hydrogel particles were obtained.

[0039] (2) According to acrylamide, graphene-coated cellulose hydrogel particles, N,N-methylenebisacrylamide, N,N,N',N'-tetramethylethylenediamine and ammonium persulfate The material ratio is 8:1.3:0.15:0.45:0.75, add graphene-coated cellulose hydrogel particles to the acrylamide solution, mix well, add the crosslinking agent N,N-methylenebisacrylamide After mixing with the catalyst N,N,N',N'-tetramethylethylenediamine, add the initiator ammonium persulfate, stir and polymerize at 35°C for 16 hours to obtain a graphene / cellulose / polyacryl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com