In-situ device for testing absorption spectrum of synchrotron radiation X rays of battery electrode material

A battery electrode and X-ray technology, applied in the field of in-situ devices of synchrotron radiation X-ray absorption spectroscopy, can solve problems such as poor performance, capacity loss, poor stability, etc., and achieve the effect of overcoming non-repeatability, simple operation and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

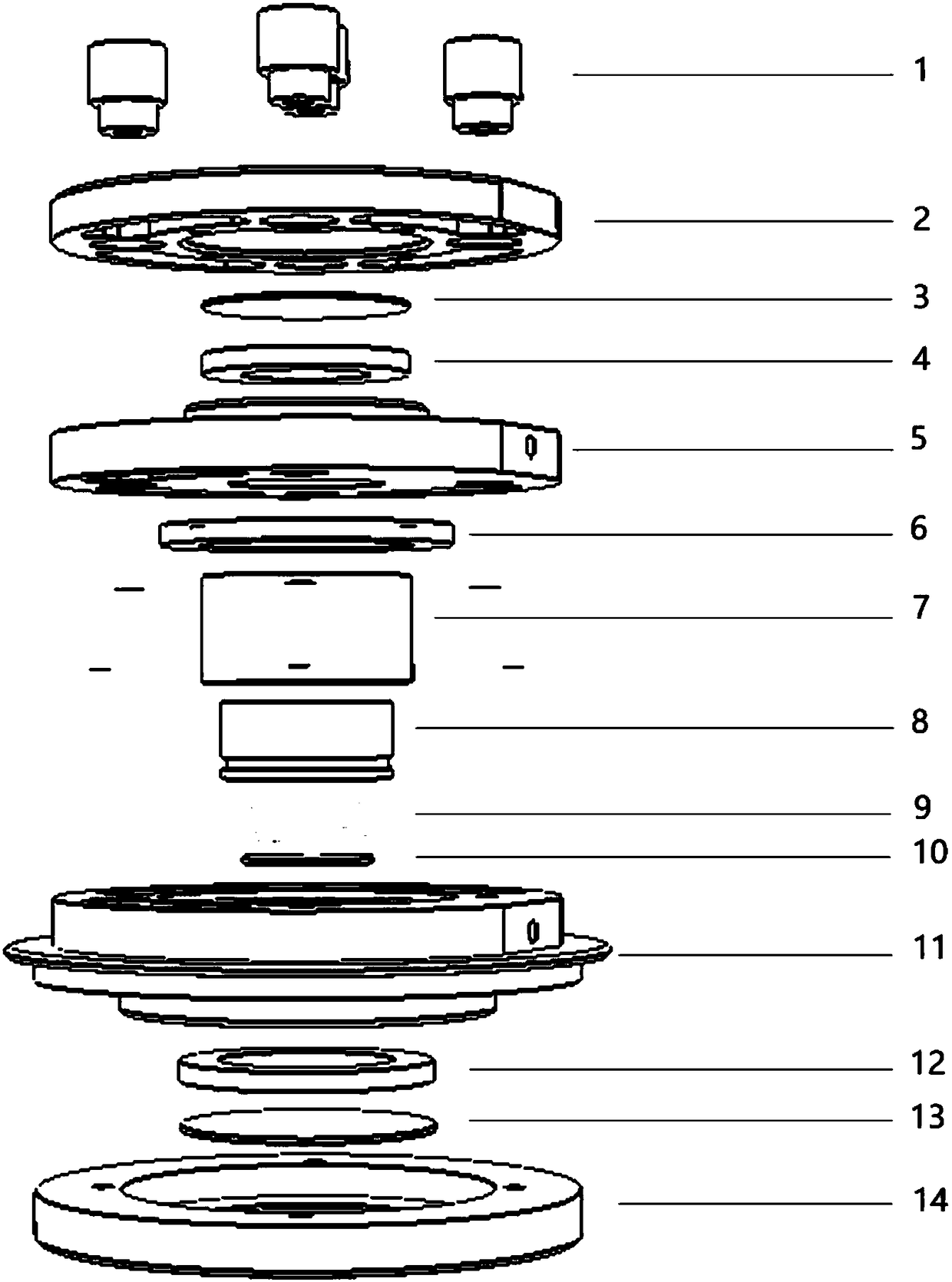

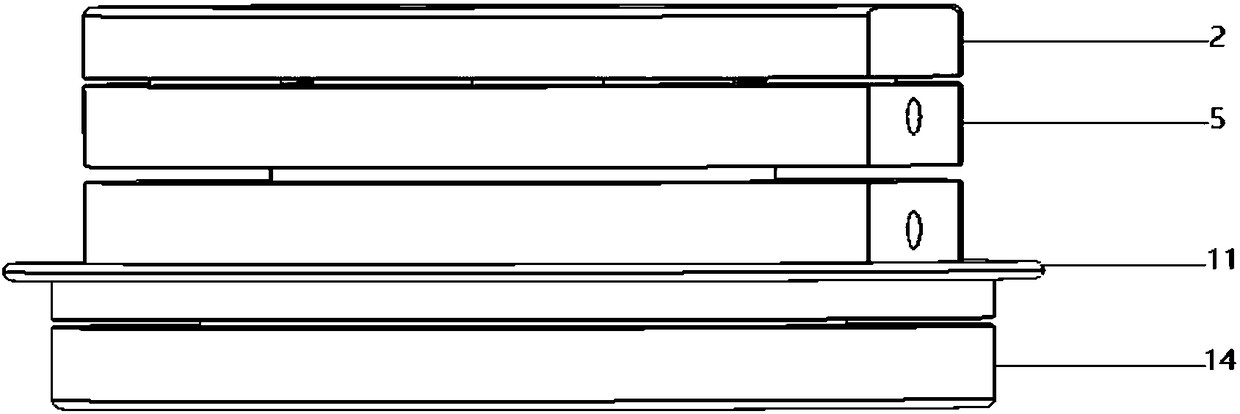

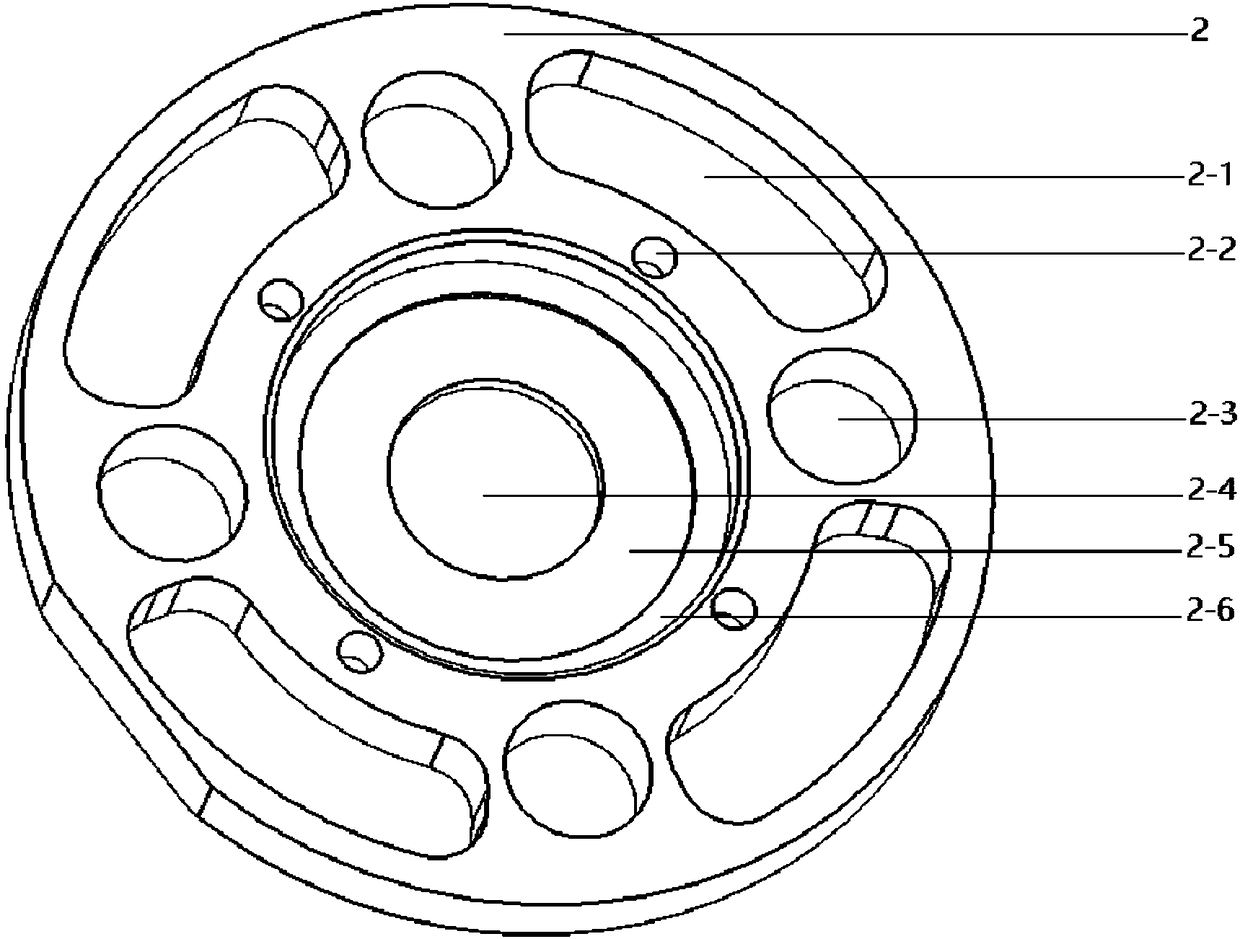

[0052] Depend on Figure 1 to Figure 6 As shown, the present invention provides a synchrotron radiation X-ray absorption spectroscopy device for analyzing the electrochemical properties of electrode materials, including: a negative electrode part, an internal insulation and pressure part, and a positive electrode part. The negative pole part includes negative pole a, beryllium sheet a, rubber ring a, negative pole b and four insulating sleeves, and the negative pole a and negative pole b are provided with threaded through holes, insulating sleeve through holes and light-transmitting through holes; The beryllium sheet a is located at the light-transmitting hole between the negative electrode a and the negative electrode b, and the insulating sleeve is used to insulate and fix the entire device. The internal insulation and pressure part includes a rubber ring b, a polytetrafluoroethylene sleeve, a spring, a top sheet and a beryllium sheet b, the beryllium sheet b is fixed on the...

Embodiment 1

[0057] with V 2 C-Sn is used as the active material of the working electrode, N-methylpyrrolidone (NMP) is used as the solvent, it is ground and mixed with the conductive agent acetylene black (AB) and the binder vinylidene fluoride (PVDF), and then the slurry is The material is evenly coated on the aluminum foil, dried overnight in a vacuum oven at 110°C, then rolled on a tablet press to make it compact, and finally cut out electrode sheets with a diameter of 16mm on a slicer. When the battery is assembled, the following steps need to be operated in a glove box filled with high-purity argon, and the water content and oxygen content are both less than 0.1ppm. First combine the positive electrode a and the positive electrode b, tighten the four screws on the positive electrode part; snap the polytetrafluoro sleeve into the groove of the positive electrode a, and then put the cut electrode piece into the polytetrafluoro sleeve of the device of the present invention In the cylin...

Embodiment 2

[0064] with V 2 C-Sn is used as the active material of the working electrode, N-methylpyrrolidone (NMP) is used as the solvent, it is ground and mixed with the conductive agent acetylene black (AB) and the binder vinylidene fluoride (PVDF), and then the slurry is The material is evenly coated on the aluminum foil, dried overnight in a vacuum oven at 110°C, then rolled on a tablet press to make it compact, and finally cut out electrode sheets with a diameter of 16mm on a slicer. When the battery is assembled, the following steps need to be operated in a glove box filled with high-purity argon, and the water content and oxygen content are both less than 0.1ppm. First combine the positive electrode a and the positive electrode b, tighten the four screws on the positive electrode part; snap the polytetrafluoro sleeve into the groove of the positive electrode a, and then put the cut electrode piece into the polytetrafluoro sleeve of the device of the present invention In the barre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com