Preparation method of livestock and poultry bone collagen peptide chelated calcium

A technology for polypeptide chelated calcium and bone collagen, which is applied to the functions of food ingredients, food ingredients, protein food ingredients, etc., can solve problems such as loopholes, unfavorable industrial production, and inconsistent preparation process of collagen polypeptide chelated calcium, and achieve Simplify the production process, meet intake requirements, and optimize the effect of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

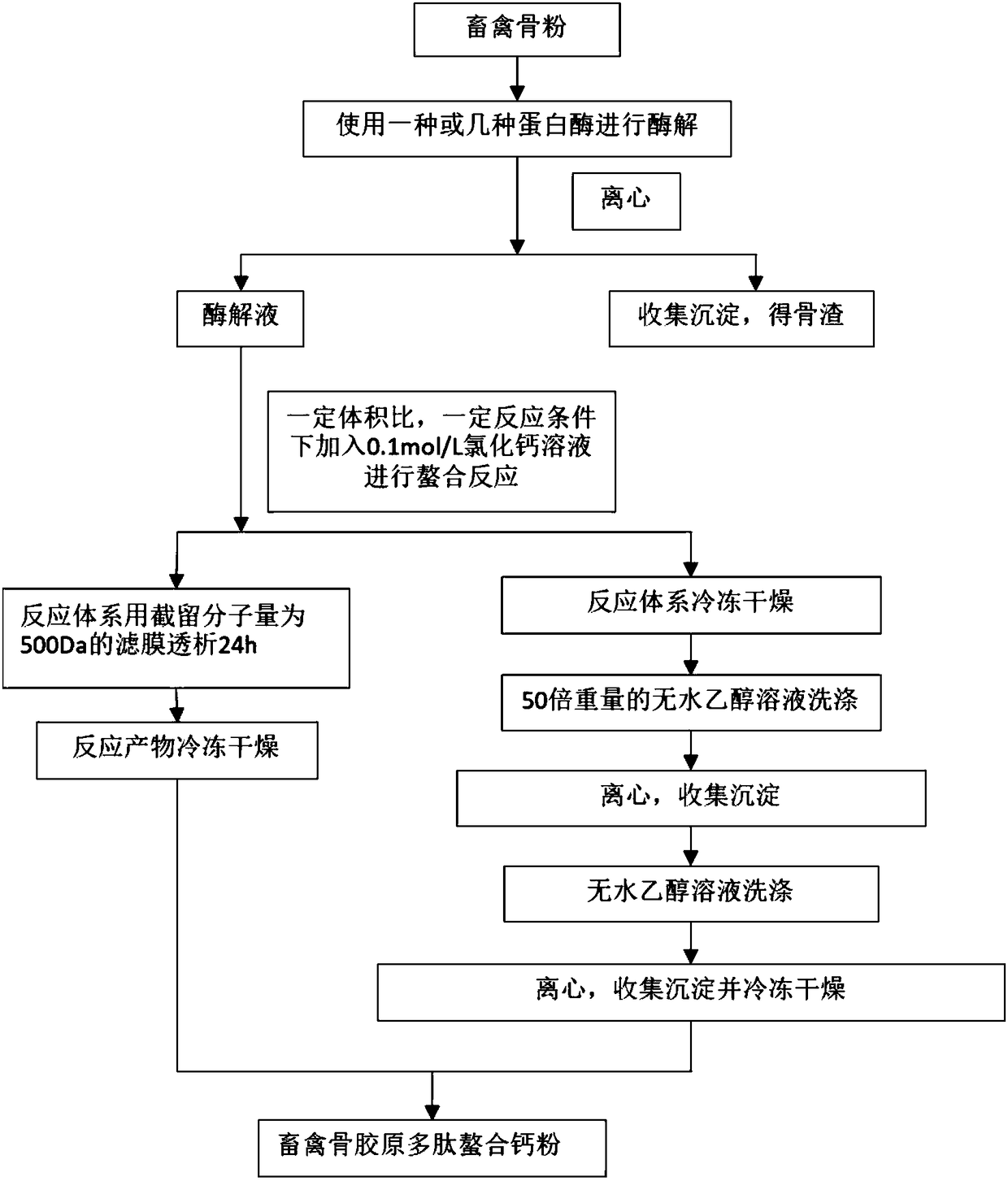

Method used

Image

Examples

Embodiment 1

[0065] First, crush fresh deer bones into small pieces of 5cm-10cm, remove the tendons, skin, bone marrow and a small amount of meat on them, wash and drain, cook in a pressure cooker at 80kPa for 1 hour, remove the cooking liquid, rinse with cold water to remove fat, and drain Dry it, then dry it with hot air at 60°C for 6 hours, and pulverize the dried deer bone pieces with an ultrafine pulverizer to obtain deer bone powder.

[0066] Use compound protease to enzymatically hydrolyze deer bone powder, the optimal enzymolysis conditions are: substrate concentration 5%, the weight ratio of enzyme and substrate is 8 / 1000, the pH value of the reaction system is 6.5 (adjusted with 1mol / L HCl solution), and the reaction temperature 55°C, the enzymatic hydrolysis time is 4h. Under optimal enzymolysis conditions, the enzymolysis solution containing deer bone collagen polypeptide was obtained, and the enzymolysis solution of deer bone powder, distilled water and 0.1mol / L CaCl 2 The so...

Embodiment 2

[0069] First, crush fresh deer bones into small pieces of 5cm-10cm, remove the tendons, skin, bone marrow and a small amount of meat on them, wash and drain, cook in a pressure cooker at 80kPa for 1 hour, remove the cooking liquid, rinse with cold water to remove fat, and drain Dry it, then dry it with hot air at 60°C for 6 hours, and pulverize the dried deer bone pieces with an ultrafine pulverizer to obtain deer bone powder.

[0070] Use compound protease to enzymatically hydrolyze deer bone powder, the optimal enzymolysis conditions are: substrate concentration 5%, the weight ratio of enzyme and substrate is 8 / 1000, the pH value of the reaction system is 6.5 (adjusted with 1mol / L HCl solution), and the reaction temperature 55°C, the enzymatic hydrolysis time is 4h. Under optimal enzymolysis conditions, the enzymolysis solution containing deer bone collagen polypeptide was obtained, and the enzymolysis solution of deer bone powder, distilled water and 0.1mol / L CaCl 2 The so...

Embodiment 3

[0073] First, crush the fresh beef leg bones into small pieces of 5cm-10cm, remove tendons, skin, bone marrow and a small amount of meat on them, wash and drain, cook in a high-pressure reactor at 80MPa for 1 hour, remove the cooking liquid, and rinse with cold water Degrease, drain, and then dry with hot air at 60°C for 7 hours, and pulverize the dried deer bone pieces with an ultrafine pulverizer to obtain deer bone powder.

[0074] Use flavor protease and hydrolyzing protease double enzymolysis bovine bone powder, optimal enzymolysis condition is: first use flavor protease, in substrate concentration 5%, the weight ratio of enzyme and substrate is 8 / 1000, and the pH value of reaction system is 7.5 ( Use 1mol / L HCl and 1mol / L NaOH to adjust), the reaction temperature is 50°C, the enzymolysis time is 2.5h to enzymatically hydrolyze bovine bone powder, and the enzyme is inactivated at 100°C for 10min, and the pH value of the reaction system is adjusted to 9.0 (use 1mol / L HCl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com