Polishing disc for polishing machine with good oxidation resistance and wear resistance, and preparation process thereof

A wear-resistant performance and polishing machine technology, which is applied in the direction of grinding/polishing equipment, manufacturing tools, abrasives, etc., can solve the problems of easily scratching the glass surface, high abrasive grain hardness, and uneven distribution of pores on the polishing disc, reaching the price Effect of low cost, high surface quality, good oxidation resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

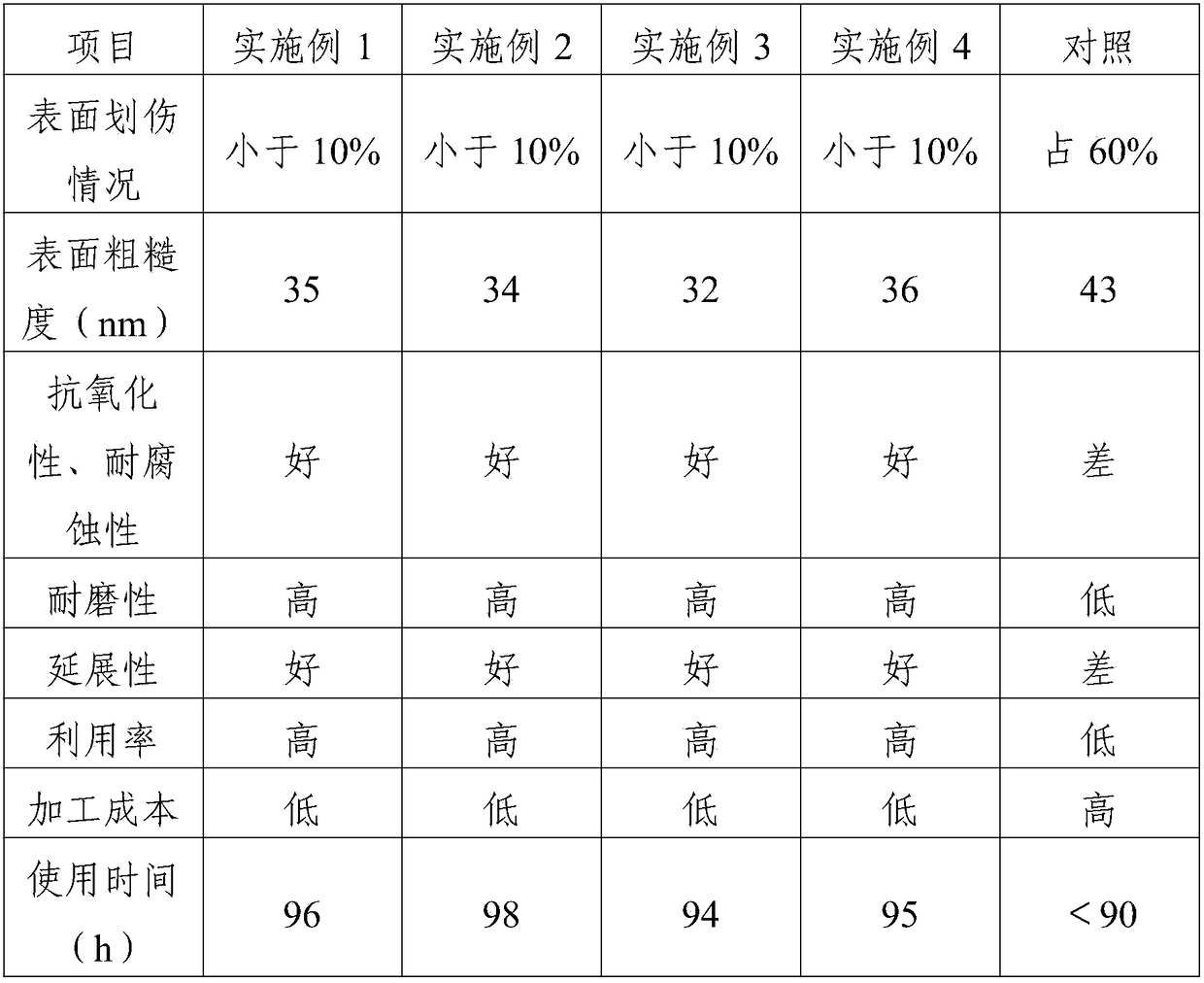

Examples

Embodiment 1

[0023] A polishing disc for a polishing machine with good oxidation resistance and wear resistance is made of the following raw materials in parts by weight:

[0024] 80 parts of asphalt, 3 parts of paraffin wax, 3 parts of microcrystalline wax, 6 parts of rosin, 1 part of porous expanded perlite, 1.5 parts of silicon dioxide, 2 parts of abrasive, 3 parts of hydrated magnesium silicate, 4 parts of petroleum grease.

[0025] Wherein, the abrasive is a mixture of diamond, boron carbide, aluminum oxide, iron oxide and cerium oxide, and the particle size of the abrasive is 0.05um.

Embodiment 2

[0027] A polishing disc for a polishing machine with good oxidation resistance and wear resistance is made of the following raw materials in parts by weight:

[0028] 100 parts of asphalt, 9 parts of paraffin, 8 parts of microcrystalline wax, 18 parts of rosin, 3 parts of porous expanded perlite, 4.5 parts of silicon dioxide, 7 parts of abrasive, 1 part of hydrated magnesium silicate, 2 parts of petroleum grease.

[0029] Wherein, the abrasive is a mixture of silicon carbide, magnesium oxide and zirconia, and the particle size of the abrasive is 3 μm.

Embodiment 3

[0031] A polishing disc for a polishing machine with good oxidation resistance and wear resistance is made of the following raw materials in parts by weight:

[0032] 90 parts of asphalt, 6 parts of paraffin wax, 5 parts of microcrystalline wax, 12 parts of rosin, 2 parts of porous expanded perlite, 3 parts of silicon dioxide, 4 parts of abrasive, 2 parts of hydrated magnesium silicate, and 3 parts of petroleum grease.

[0033] Wherein, the abrasive is a mixture of diamond, silicon carbide, boron carbide, magnesium oxide, iron oxide and cerium oxide, and the particle size of the abrasive is 1um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com