Porphyridium concentrated harvesting method and porphyridium culturing and concentrated harvesting coupling method

A technology of Porphyridum algae and algae liquid, applied in the field of marine microorganisms, can solve the problems of safety hazards, safety hazards, and process existence in high-speed operation, and achieve the effects of increasing biomass productivity, improving utilization efficiency, and reducing harvesting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

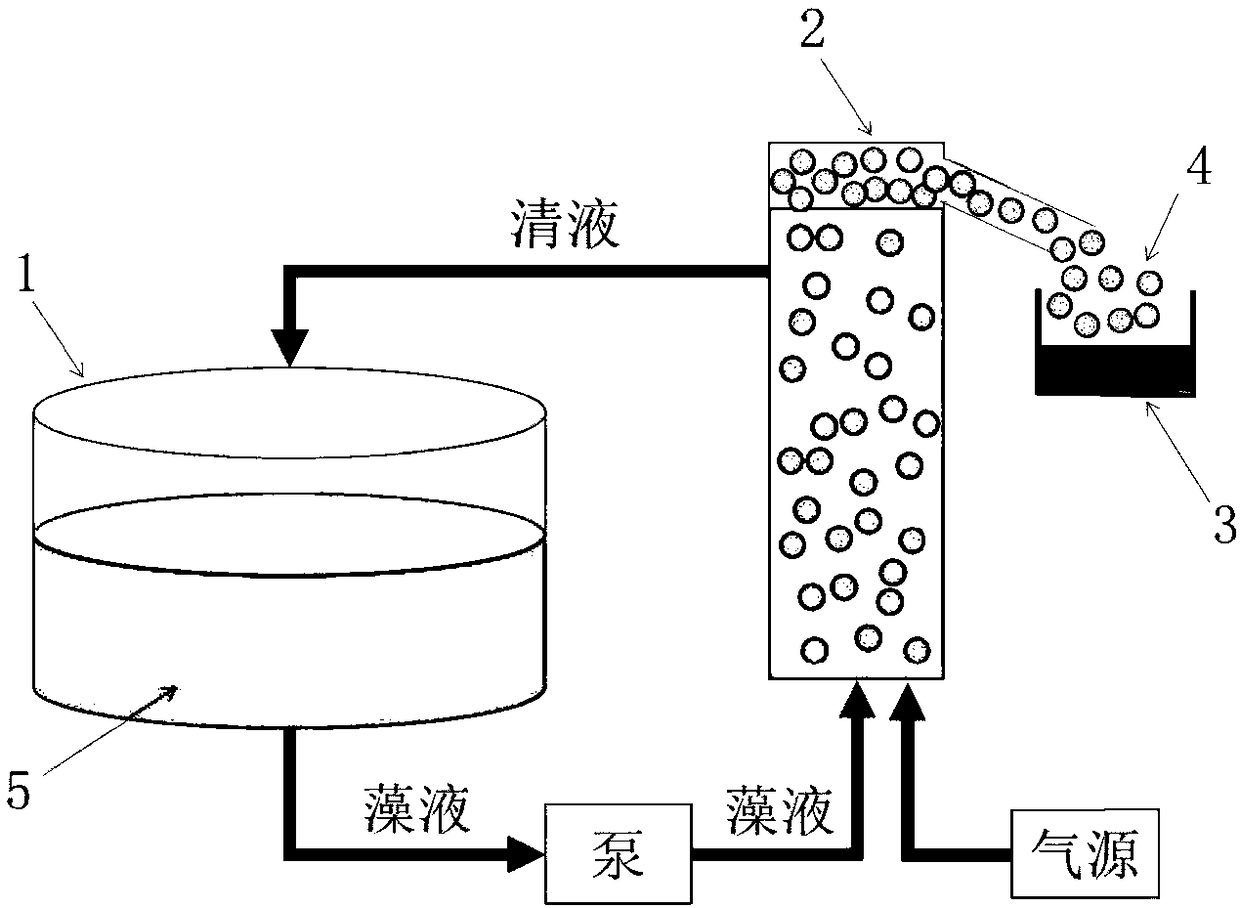

Embodiment 1

[0038] Under outdoor conditions, Porphyridum inoculated into 100L culture solution 5 (the formula of culture solution is: every liter contains sodium nitrate 1.5g, potassium dihydrogen phosphate 0.1g, iron trichloride 5mg and sodium bicarbonate 5.0g, Surplus is seawater) in the 120L culture tank 1, inoculum size is OD 750 =0.5, after culturing Porphyridium algae for 10 days at a temperature of 26°C and a light intensity of 22000Lux, the growth of Porphyridococcus reached a stable stage, and the cell density reached 3.6×10 7 cells / ml, and the exopolysaccharide content was 0.04g / L, reaching the harvest standard. Continuously input the algae liquid from the bottom of the cylindrical collection container 2 with a bottom diameter of 10 cm and a height of 100 cm into the cylindrical collection container 2 through a centrifugal pump or a diaphragm pump. The liquid flow rate is 1.0 L / min. ℃, and the light intensity is 22000Lux to continue the cultivation. When the algae liquid enters...

Embodiment 2

[0040] Under the outdoor conditions, Porphyridum inoculated into 800L culture solution 5 (the formula of culture solution is: every liter contains sodium nitrate 1.5g, potassium dihydrogen phosphate 0.1g, iron trichloride 5mg and sodium bicarbonate 5.0g, Surplus is seawater) in the 1000L culture pool 1, inoculum size is OD 750 =0.1, after culturing Porphyridium algae for 5 days at a temperature of 26°C and a light intensity of 22,000Lux, the growth of Porphyridococcus reached a stable stage, and the cell density reached 0.9×10 7 cells / ml, and the exopolysaccharide content was 0.02g / L, reaching the harvest standard. Through a centrifugal pump or a diaphragm pump, the algae liquid is continuously input from the bottom of a cylindrical collection container 2 with a diameter of 50 cm and a height of 100 cm into the cylindrical collection container 2 at a liquid flow rate of 10 L / min. ℃, and the light intensity is 22000Lux to continue the cultivation. When the algae liquid enters ...

Embodiment 3

[0042] Under outdoor conditions, Porphyridum inoculated into 100L culture solution 5 (the formula of culture solution is: every liter contains sodium nitrate 1.5g, potassium dihydrogen phosphate 0.1g, iron trichloride 5mg and sodium bicarbonate 5.0g, Surplus is seawater) in the 120L culture tank 1, inoculum size is OD 750 =0.5, after 13 days of culturing Porphyridium algae at a temperature of 26°C and a light intensity of 22000Lux, the growth of Porphyridococcus reached a stable stage, and the cell density reached 3.5×10 7 cells / ml, and the exopolysaccharide content was 0.1g / L, reaching the harvest standard. Continuously input the algae liquid from the bottom of the cylindrical collection container 2 with a diameter of 10 cm and a height of 100 cm into the cylindrical collection container 2 through a centrifugal pump or a diaphragm pump. Continue to cultivate, when the algae liquid enters the cylindrical collection container 2, the gas distributor at the bottom of the cylindr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com