Method and corresponding device for testing through pore diameters and pore diameter distribution of ultra-filtration membranes

A testing method and testing device technology, applied in the direction of measuring devices, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of affecting the membrane pore structure, the membrane pore structure is easy to be compressed and deformed, and the inability to distinguish through holes and invalid holes, etc. , to achieve the effects of high accuracy of measurement data, excellent data accuracy and reproducibility, and avoid swelling and separation layer shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

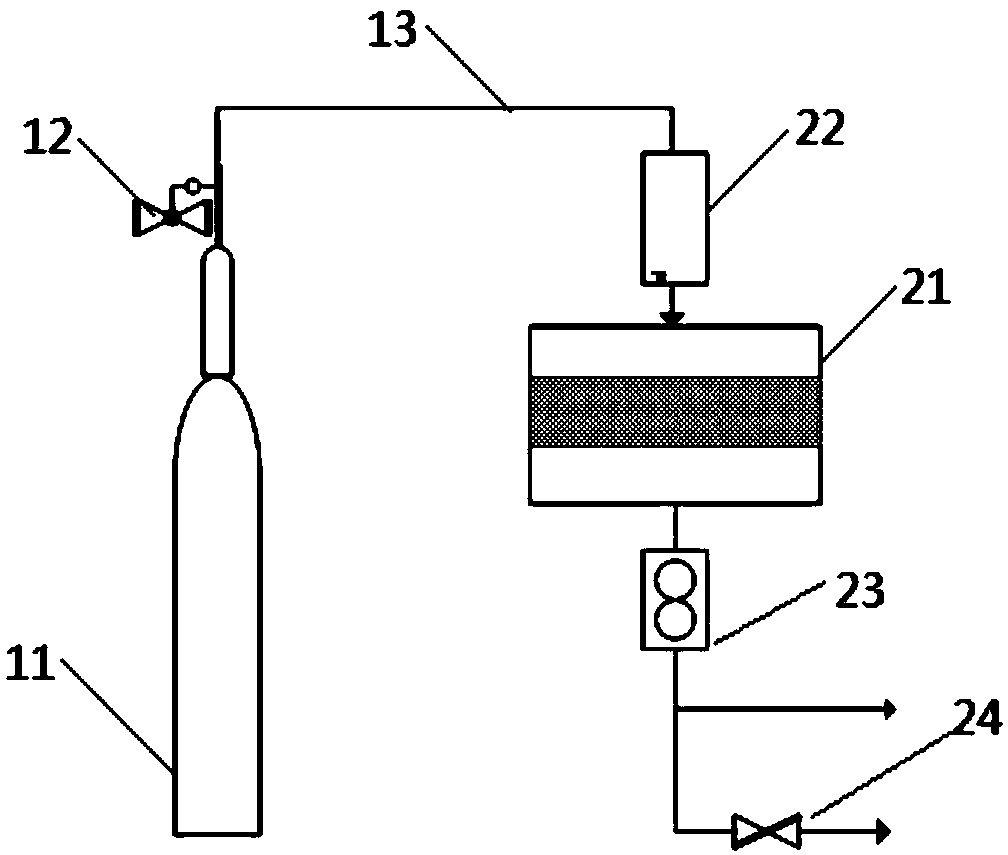

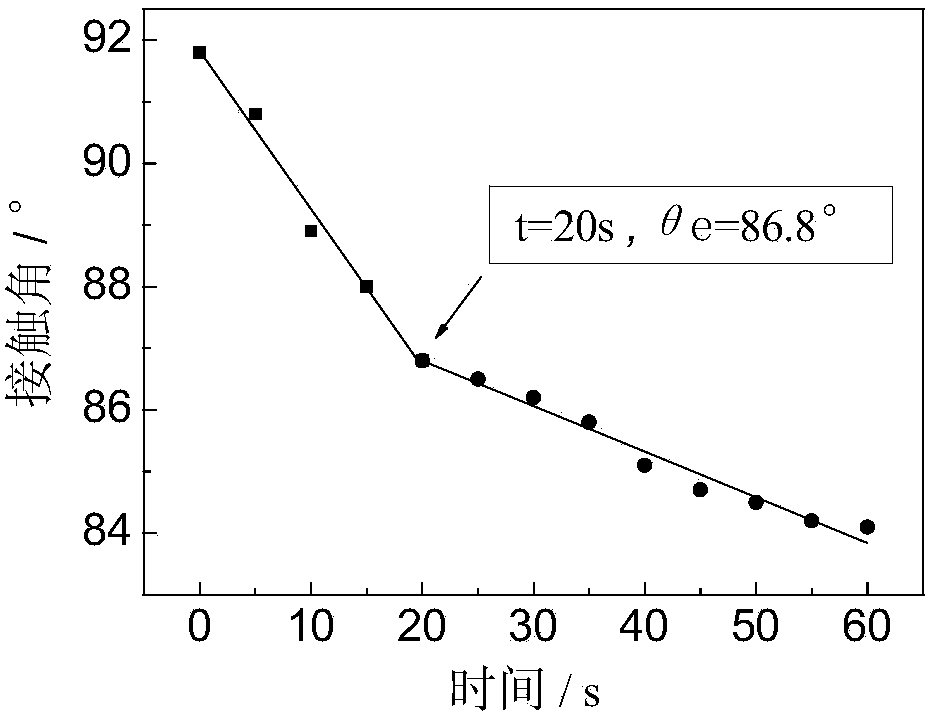

[0062] The invention provides a test device for the through-hole diameter of an ultrafiltration membrane and its distribution; it includes such as figure 1 air pressure system, dry / wet curve test unit as shown; and figure 2 The apparent contact angle test unit shown; the air pressure system includes a gas cylinder 11, a pressure reducing valve 12 and a gas pipeline 13; the gas outlet of the gas cylinder 11 is equipped with a pressure reducing valve 12; Connect with the gas cylinder 11.

[0063] The dry / wet curve test unit comprises a membrane pool 21, and the inlet end of the membrane pool 21 communicates with the gas pipeline 13; a gas pressure gauge 22 and an air inlet control valve are also installed on the pipeline at the inlet end of the membrane pool 21; the gas outlet of the membrane pool 21 A gas flow meter 23 and a waste liquid discharge port 24 are installed on the pipeline at the end.

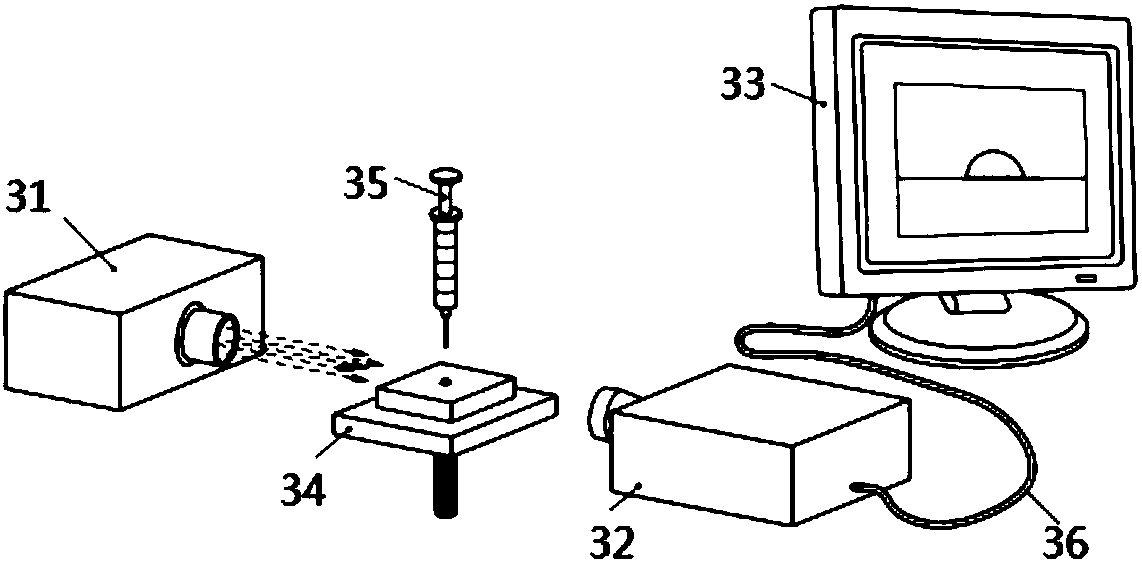

[0064] The apparent contact angle testing unit includes a light source 31 , a...

Embodiment 2

[0091]Example 2 uses the same measuring device and test steps as Example 1, the only difference being that a certain brand of mixed cellulose membrane with a nominal pore size of 25 nm is used in Example 2. Select 2 membrane samples, numbered M-25-1 and M-25-2 respectively, with a membrane thickness of 110 μm, cut the membrane into a 25mm diameter disc, soak it in distilled water, and the surface tension of the water is 72mN / m. The ultrasonic frequency is 100kHz, and the infiltration time is 4h. After infiltration, the membrane is taken out and placed in the membrane tank, which is made of stainless steel. Open the intake control valve, use the intake control valve and gas pressure gauge to control the nitrogen pressure range from 0bar to 30.0bar, and record the nitrogen flux through the membrane through the gas flowmeter. When the nitrogen flow rate and pressure increase linearly, stop Wet curve test.

[0092] Slowly increase the inlet pressure again, and record the nitroge...

Embodiment 3

[0105] Example 3 uses the same measuring device and testing procedures as Example 1, the only difference is that a certain brand of polyester nuclear pore track membrane with a nominal pore size of 30 nm is used. Select 2 film samples, numbered W-30-1 and W-30-2 respectively, with a film thickness of 20 μm. The membrane was cut into discs with a diameter of 25 mm, and soaked in distilled water with a surface tension of 72 mN / m. The ultrasonic frequency is 50kHz, and the infiltration time is 5h. After infiltration, the membrane is taken out and placed in the membrane tank, which is made of stainless steel. Open the intake control valve, use the intake control valve and gas pressure gauge to control the nitrogen pressure range from 0bar to 30.0bar, and record the nitrogen flux through the membrane through the gas flowmeter. When the nitrogen flow rate and pressure increase linearly, stop Wet curve test.

[0106] Slowly increase the inlet pressure again, and record the nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com