Self-heat supply two-section chemical activation furnace

A chemical activation, self-heating technology, applied in inorganic chemistry, chemical instruments and methods, carbon compounds, etc., can solve problems such as inability to effectively remove water vapor separation, inability to effectively reuse combustible gases, and achieve high recycling value. , to achieve the efficient use of energy, to achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

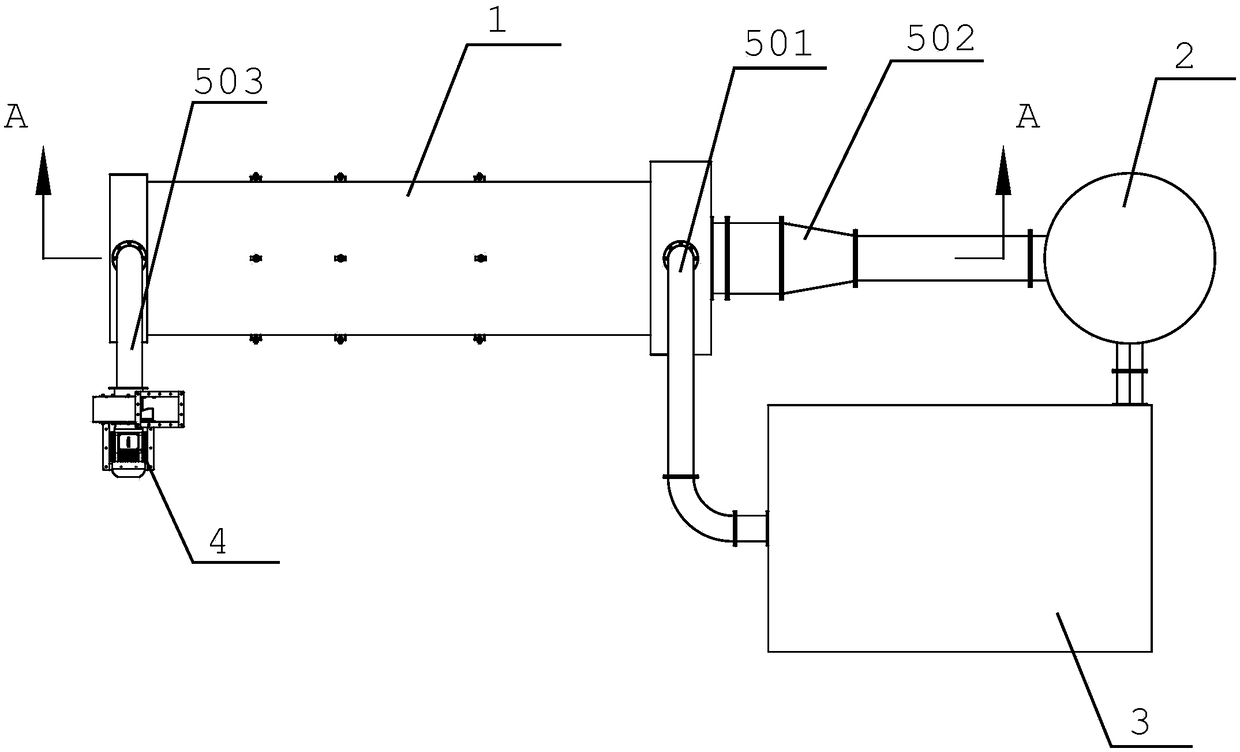

[0034] Such as figure 1 A kind of self-heating type two-stage chemical activation furnace shown, it comprises activation reaction furnace 1, is connected on the exhaust pipe 503 on the activation reaction furnace 1, inlet pipe 502 and outlet pipe 501, the other part of exhaust pipe 503 One end is connected to the fan 4 , the other end of the outlet pipe 501 is connected to the combustion furnace 3 , the combustion furnace 3 is connected to the waste heat boiler 2 , and the waste heat boiler 2 is connected to the activation reaction furnace 1 through the intake pipe 502 . The activated carbon raw material 8 enters the activation reaction furnace 1 from one end of the activation reaction furnace 1 connected with the exhaust pipe 503, and slowly advances to the other end of the activation reaction furnace 1, during which carbonization and activation are realized.

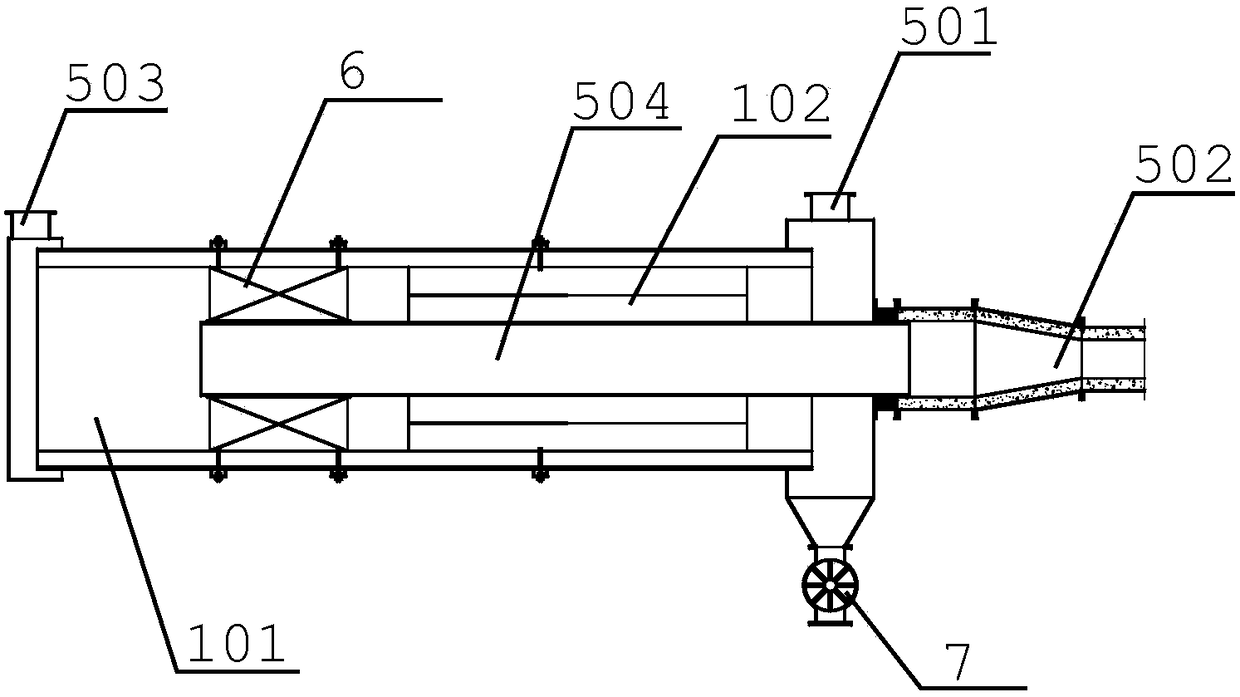

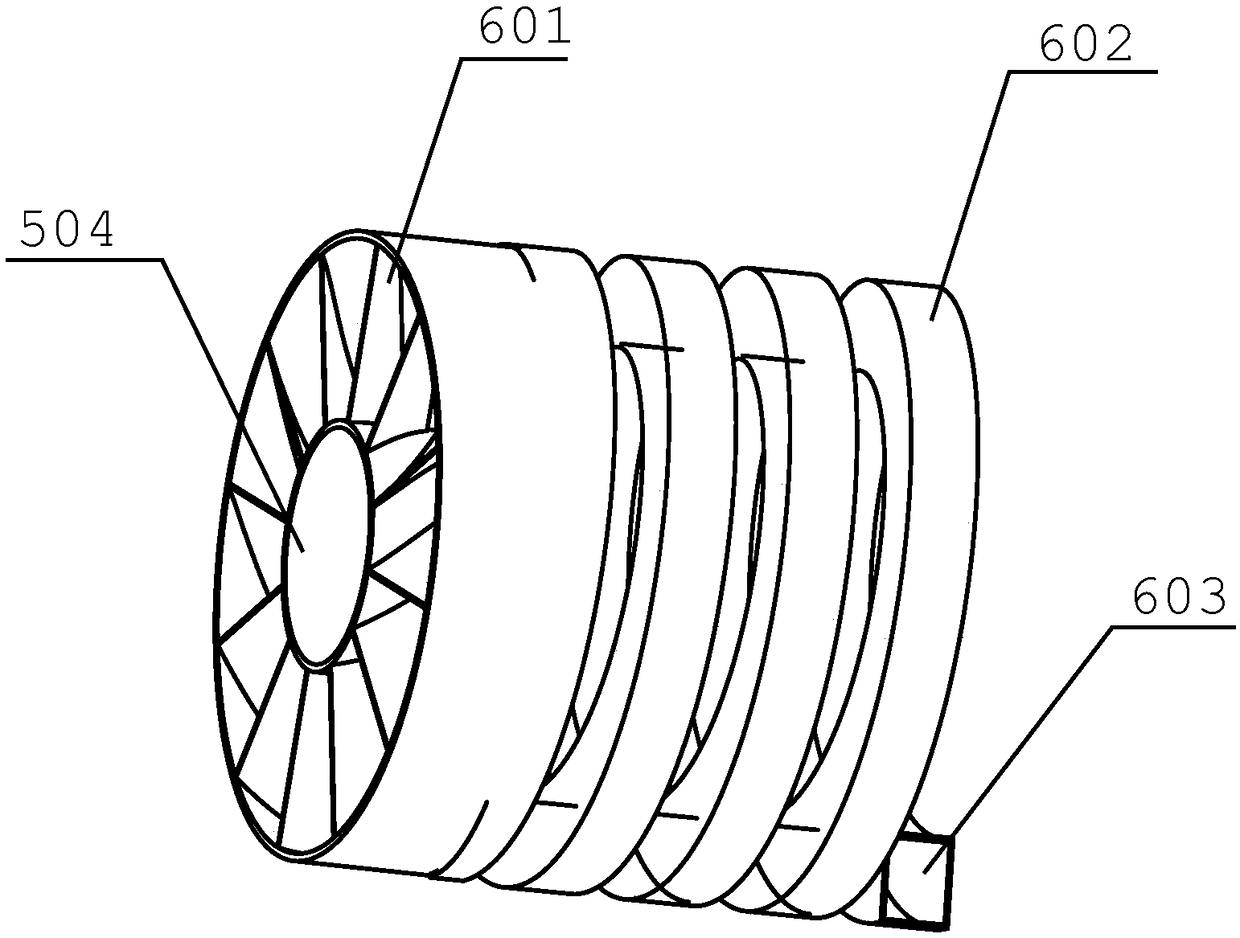

[0035] Such as figure 2As shown, the inner cavity of the activation reaction furnace 1 is provided with a screw fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com