Preparation method for 2,4-dichlorophenol, and preparation method for 2,4-dichlorophenolate

A technology of dichlorophenol and dichlorophenate, applied in the chemical industry, can solve problems such as poor appearance of products, influence on use, etc., and achieve the effects of simple process, guaranteed reaction rate, and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

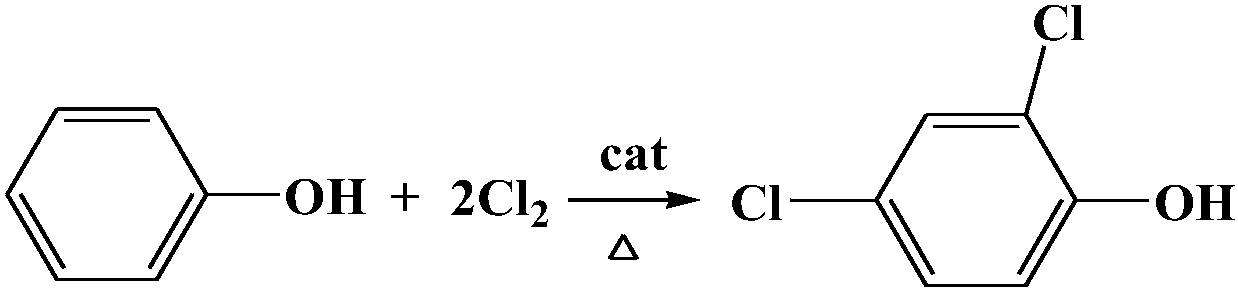

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of 2,4-dichlorophenol, comprising: S) chlorinating phenol, an accelerator and sulfuryl chloride in an organic solvent under low temperature conditions to obtain 2,4-dichlorophenol Chlorophenol; the accelerator is selected from one or more of dimethyl sulfide, phenylene sulfide and isopropyl ether.

[0031] The present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0032] Phenol, accelerator and sulfuryl chloride are chlorinated in an organic solvent under low temperature conditions; the accelerator is one or more of dimethyl sulfide, phenylene sulfide and isopropyl ether; the The quality of the accelerator is 0.1% to 10% of the phenol mass, more preferably 0.5% to 5%; the organic solvent is an organic solvent well known to those skilled in the art, and there is no special limitation. In the present invention, it is preferably One or more in methylene dichloride,...

Embodiment 1

[0044] 1.1 Dissolve 100g of phenol and mix with 100g of tetrachlorethylene, then add 0.5g of dimethyl sulfide, lower to -10°C, then add 287g of sulfuryl chloride dropwise, and carry out chlorination reaction. The dropwise addition time is 5h. After the reaction is completed, the mixture containing The reaction solution of 2,4-dichlorophenol; the normalized content of 2,4-dichlorophenol is 99.53%, and the yield is 99.3%.

[0045]1.2 Add 30% sodium hydroxide solution to the reaction liquid containing 2,4-dichlorophenol until the pH of the solution is 12, and the neutralization temperature is 50°C, and let stand to separate to obtain the aqueous phase and the organic phase; The water phase was dehydrated to obtain 197.5 g of anhydrous 2,4-dichlorophenol sodium salt, with a yield of 99.2%; the organic phase was refluxed with water, and the water was extracted until the water content was less than 0.2%, and then returned to 1.1, and phenol was added , cooling and then adding sulfur...

Embodiment 2

[0047] 200g ethanol, 95g (1mol) chloroacetic acid and 0.1g concentrated sulfuric acid were mixed and stirred, and desolvated and dehydrated for 5h to obtain ethyl chloroacetate; 186g (1mol) of 2,4-dichlorophenate sodium obtained in Example 1 was added and kept warm Stir for 3 hours, filter out the solid sodium chloride generated by the reaction, remove ethanol from the filtrate to obtain ethyl 2,4-dichlorophenoxyacetate, add 125g of 32% sodium hydroxide solution, keep stirring at 100°C for 2 hours, add 50% sulfuric acid 100 g was crystallized at 10°C for 1 h, filtered, and the filter cake was dried to obtain 221 g of 2,4-dichlorophenoxyacetic acid solid with a purity of 99.5% and a yield of 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com