Adhesive resin, adhesive composition, layered bonded composite using the adhesive composition, and outer packaging for lithium batteries

An adhesive layer, composition technology, applied in the direction of synthetic resin layered products, adhesive types, battery boxes/jackets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

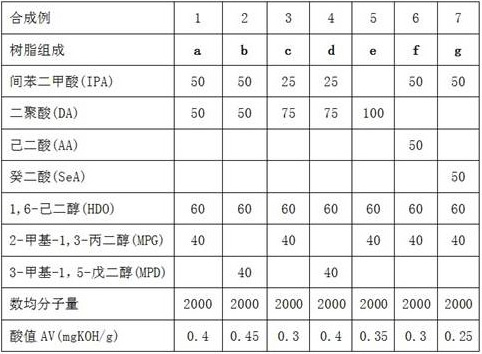

[0047] Synthesis Example 1: This synthesis example includes adding 166. grams (1.0 mol) of isophthalic acid (IPA) in sequence to a four-necked reaction flask equipped with a stirrer, a thermometer, a condenser, and a nitrogen conduit, and 1,6-hexane Diol (HDO) 177.3 grams (1.5mol), 2-methyl-1,3-propanediol (MPG) 90.1 grams (1mol) and catalyst tetrabutyl titanate 0.1 grams (about 0.3mmol), under nitrogen, 180 Carry out dehydration esterification reaction at -220°C. After removing about 36 grams of quantitatively generated water, add 560.9 grams (1mol) of hydrogenated dimer acid (HDA), start high vacuum at 220°C, and drop to about 200Pa within 40 minutes, further The polyester polyol a with a number-average molecular weight of about 2000 is obtained through esterification, and the composition ratio of molecular weight to main body is IPA:HAD:HDO:MPG 50:50:60:40. (As shown in Table 1).

Synthetic example 2

[0048] Synthesis example 2: use 3-methyl-1,5-pentanediol (MPD) 118.2. grams (1.0mol) to replace 2-methyl-1,3-propanediol (MPG) in synthesis example 1, other and synthetic Same as Example 1, polyester polyol b with a number average molecular weight of about 2000 was obtained, and the molecular weight main composition ratio IPA:HAD:HDO:MPD was 50:50:60:40.

Synthetic example 3

[0049] Synthesis Example 3: In a four-necked reaction flask equipped with a stirrer, a thermometer, a condenser, and a nitrogen conduit, 83.1 grams (0.5 mol) of isophthalic acid (IPA), 1,6-hexanediol (HDO) 177.3 gram (1.5 mol), 90.1 gram (1.0 mol) of 2-methyl-1,3-propanediol (MPG) and 0.1 gram (about 0.3 mmol) of tetrabutyl titanate as a catalyst, and dehydrate at 180-220°C under nitrogen Esterification reaction. After removing about 18 grams of quantitatively generated water, add 841.4 grams (1.5 mol) of hydrogenated dimer acid (HDA), start a high vacuum at 220 ° C, drop to about 200 Pa within 40 minutes, and further esterify to obtain a number average molecular weight of about 2000 The polyester polyol c. The molecular weight main body composition ratio IPA:HAD:HDO:MPG is 25:75:60:40, and other parts in this synthesis example are the same as synthesis example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com