A method for producing cellulase by fermenting corn stalk furfural residue with mixed bacteria

A corn stalk and cellulase technology, which is applied in the field of cellulase production from corn stalk furfural slag mixed with bacteria, can solve the problems of unfavorable production of cellulase by Trichoderma reesei, decreased enzyme activity of filter paper, and low enzyme activity of filter paper. Achieve good economic and social benefits, high substrate concentration, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Cellulase produced by mixed bacteria fermentation

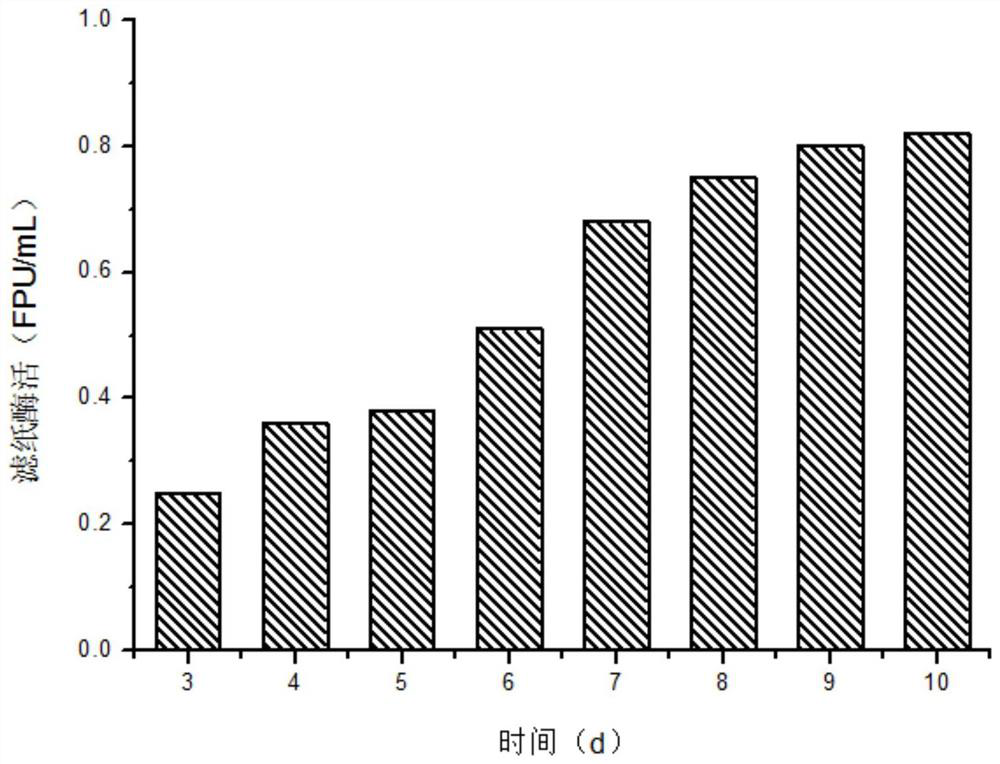

[0044] The Trichoderma reesei CICC13052 and CICC40360 preserved on the slant were respectively activated, transferred from the spore suspension to the seed culture solution with a 5% inoculation amount, and cultured on a shaker at 28° C. and 180 rpm for 24-48 hours. Then transfer it to the enzyme-producing medium containing 50g / L furfural slag at an inoculation ratio of 1:1 and a total inoculation amount of 5%, and take samples at regular intervals to determine the enzyme activity. The result is as figure 1 It was shown that the cellulase activity of the mixed bacteria could reach 0.82 FPU / mL when 50 g / L corn stalk furfural residue was used as the induced carbon source.

Embodiment 2

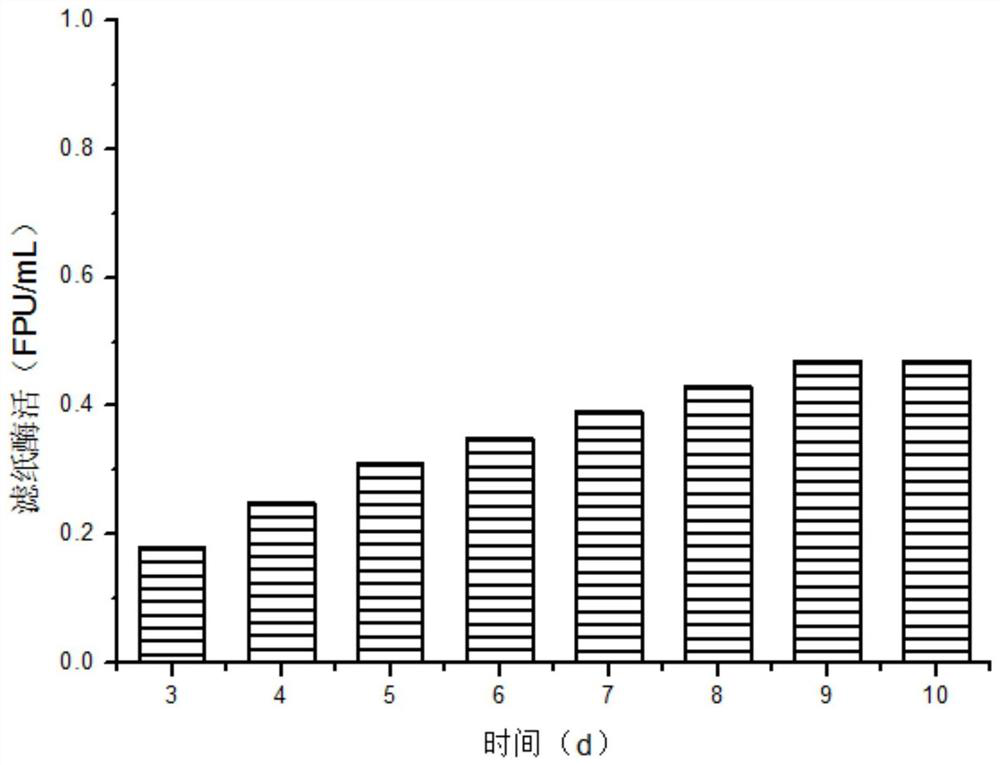

[0052] Effects of Different Substrate Concentrations on Enzyme Production by Mixed Bacteria Fermentation

[0053] According to the method described in Example 1, the mixed bacteria were transferred to the enzyme-producing medium with different concentrations of furfural slag at an inoculation ratio of 1:1 and a total inoculation amount of 5%, and samples were taken at regular intervals to determine the enzyme activity to explore its optimal carbon source. content and enzyme production. The result is as Figure 4 As shown, it can be seen from the figure that the mixed bacteria have better substrate tolerance, even at the concentration of 200g / L furfural residue, they can also ferment and produce enzymes. When 100g / L furfural residue is used as the induced carbon source, the cellulose The maximum enzyme activity can reach 0.87FPU / mL, so the substrate concentration in subsequent tests is preferably 100g / L.

Embodiment 3

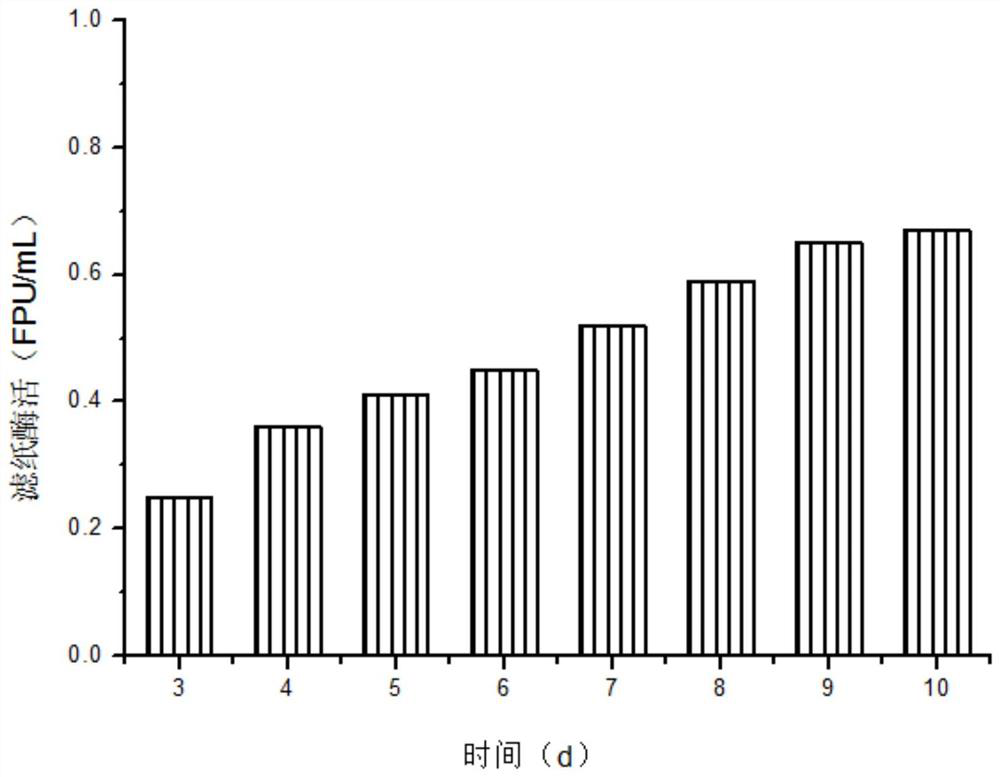

[0055] Effects of Different Initial pH on Enzyme Production by Mixed Bacteria Fermentation

[0056] The pH of the medium is closely related to the growth and reproduction of cells and the production of enzymes by fermentation. During the fermentation process, with the growth and reproduction of cells and the accumulation of metabolic products, the pH of the medium often changes, so this experiment only controls the initial pH .

[0057] According to the method described in Example 2, the mixed bacteria are transferred to the product containing 100g / L furfural slag with an initial pH of 2.80, 4.32, 4.80, 6.00, 7.00, 8.00 with an inoculation ratio of 1:1 and a total inoculation amount of 5%. Fermentation was carried out in the enzyme medium, samples were taken regularly to measure the enzyme activity, the effect of the initial pH on the enzyme production of the mixed bacteria fermentation was observed, and the optimal initial pH and enzyme production were explored. The result i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com