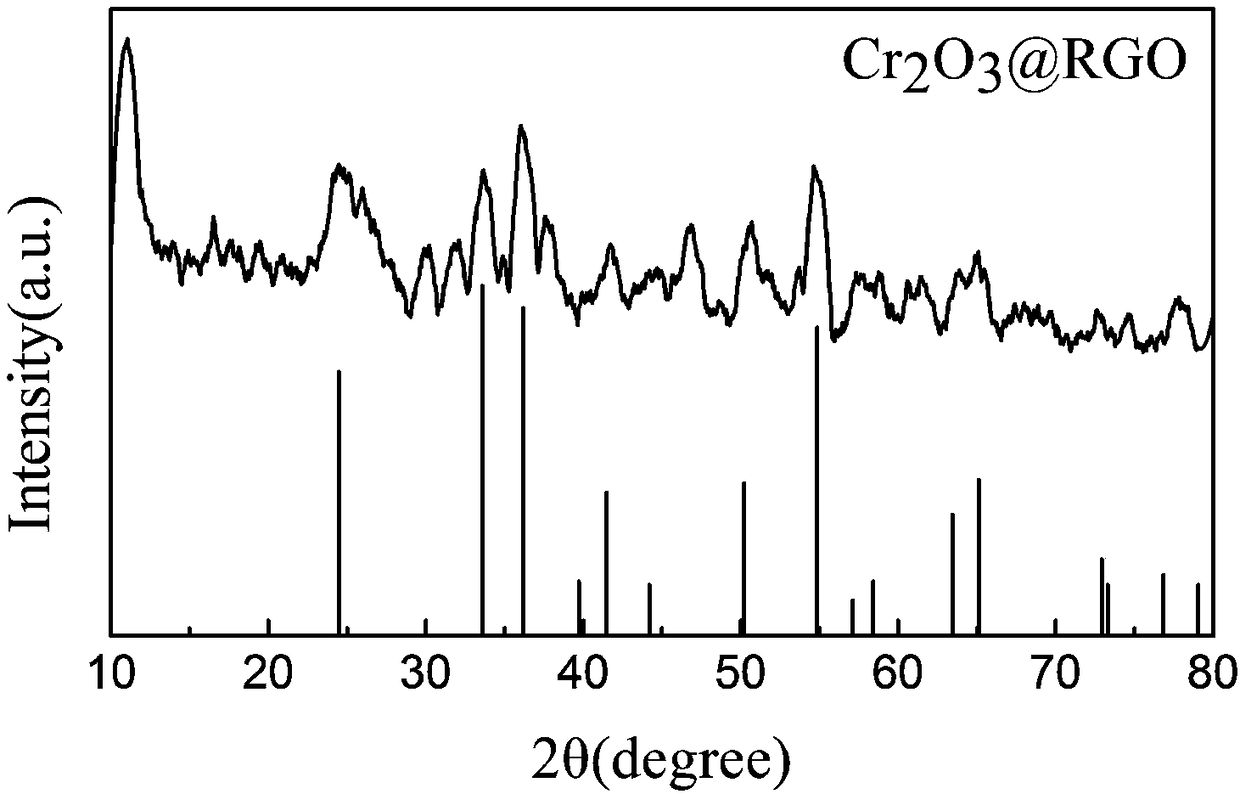

Cr2O3 supported reduced graphene oxide lithium battery anode material and preparation method

A technology of chromium trioxide and negative electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of large volume, poor conductivity, and poor battery cycle performance, and achieve high specific capacity, good conductivity, and practicality long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In one embodiment of the present invention, the present invention provides a kind of preparation method of chromium trioxide supported redox graphene lithium battery negative electrode material, comprises the steps:

[0029] S101: preparing graphene oxide solution and chromium chloride hexahydrate solution;

[0030] The graphene used is prepared by the Hummer method: 115ml of concentrated sulfuric acid is added to a 500ml dry beaker, 3g of graphite powder is added, poured while stirring, then 0.5g of potassium nitrate is added, and 15g of potassium permanganate is added under an ice-water bath for 4 hours Add in, magnetically stir overnight, mix well, and get a dark green viscous substance, add 200ml of water in an ice-water bath, slowly pour in, heat for 1 hour, slowly add 15ml of hydrogen peroxide (30%) and gradually oxidize to brownish yellow, stir at room temperature After 30 minutes, centrifuge and wash (2 times with dilute sulfuric acid, 3 times with water), and p...

Embodiment 1

[0046] Prepare 3g / L graphene oxide solution, dissolve 0.005mol chromium chloride hexahydrate in 10ml water, add 4ml graphene oxide solution, ultrasonic for 40min, put in 40℃ oven for 8h, then put the molten sample into porcelain Put the boat into a tube furnace, raise it from 25°C to 400°C in an argon atmosphere, keep it at 3°C per minute, keep it warm for 1h, and cool it down to room temperature naturally to obtain the negative electrode material of redox graphene lithium battery supported by chromium trioxide .

Embodiment 2

[0048] Prepare 5g / L graphene oxide solution, dissolve 0.01mol chromium chloride hexahydrate in 20ml water, add 6ml graphene oxide solution, ultrasonicate for 50min, put in 60°C oven for 10h, then put the molten sample into porcelain Put the boat into a tube furnace, raise it from 25°C to 500°C in an argon atmosphere, keep it at 3°C per minute, keep it warm for 2 hours, and cool it down to room temperature naturally to obtain the negative electrode material of redox graphene lithium battery supported by chromium trioxide .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com