Fe/PIL/MWCNTs fuel cell catalyst and preparation method thereof

A fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as the gap in catalytic activity and stability, and achieve the effects of expanding types, simple methods, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Take 1g of multi-walled carbon nanotubes and place them in a 250mL three-necked flask, pour 100mL of concentrated nitric acid into it, and pickle at 118°C for 6 hours. into a 250mL three-necked flask, pour 100mL concentrated hydrochloric acid and pickle at 105°C for 6h, cool to room temperature after the reaction and filter, then wash with deionized water until neutral, and dry in a vacuum oven at 50°C. acidified multi-walled carbon nanotubes.

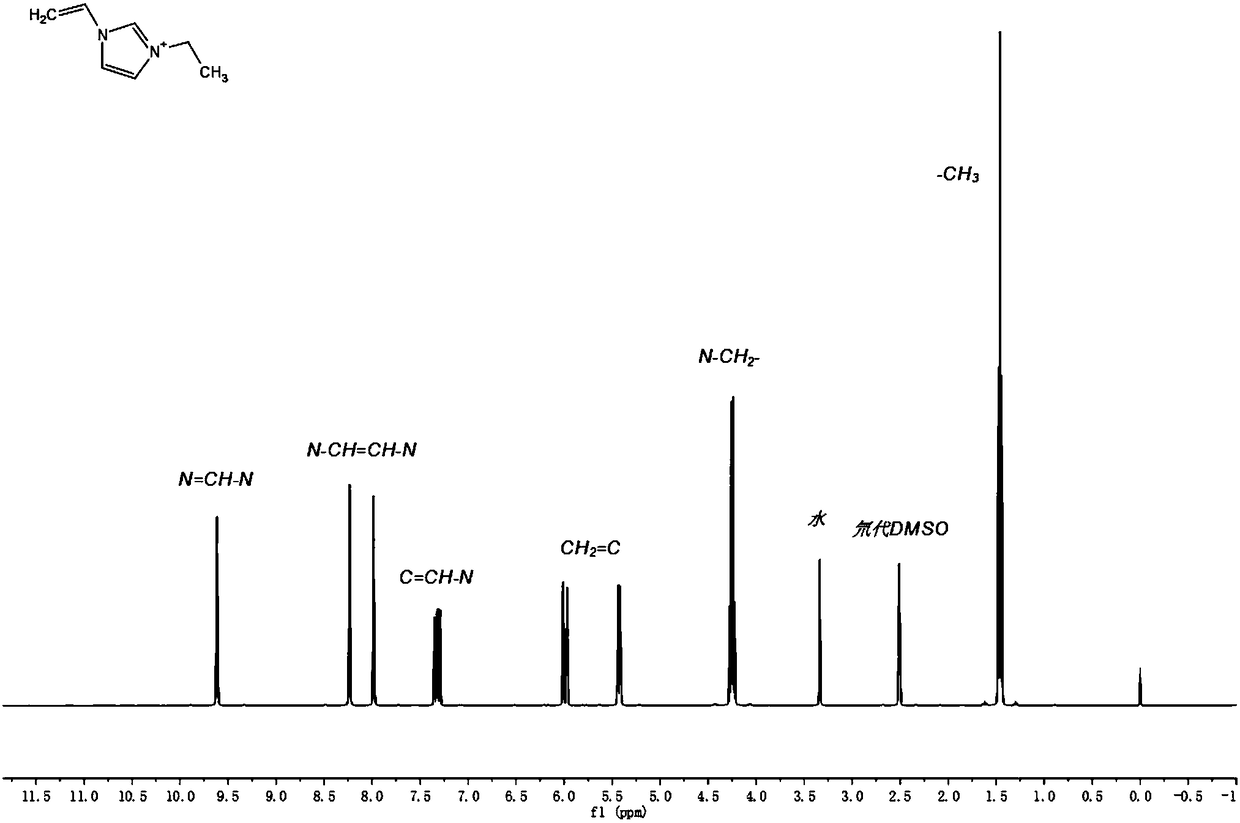

[0028] (2) Add 9.00g of 1-vinylimidazole, 28.88g of bromoethane and 50mL of acetonitrile into a 100mL three-necked flask equipped with a nitrogen valve, a magnet, and a condenser, and put it in an oil bath at 70°C under nitrogen protection for 24 hours, and react Immediately after the end, transfer the solution to a beaker and add a certain amount of diethyl ether until a white solid precipitates out of the solution, then filter and wash with diethyl ether for 3 times, and finally put the white product at 50°C for vacuum dry...

Embodiment 2

[0033] (1) step is general embodiment 1

[0034] (2) step is general embodiment 1

[0035] (3) steps pass embodiment 1

[0036] (4) Add the MWCNTs in step (1) and the PIL in step (3) in the ratio of mass ratio 1:3.75, 1:7.5, 1:11.25, 1:15 respectively in the 250mL three-neck flask, wherein in each ratio 0.4g of MWCNTs, and 60mL of ethanol was added for dispersion and dissolution, another 2.98g of Fe(NO3)3·9H2O was dissolved in 50mL of ethanol to obtain an ethanol solution of ferric nitrate, and then this solution was dropped into the three-necked flask for mixing solution, reacted at room temperature for 12 hours, then centrifuged the product, washed with alcohol, dried in a vacuum oven at 50°C for 8 hours, and ground into powder to obtain Fe / PIL / MWCNTs catalyst precursors with different nitrogen contents.

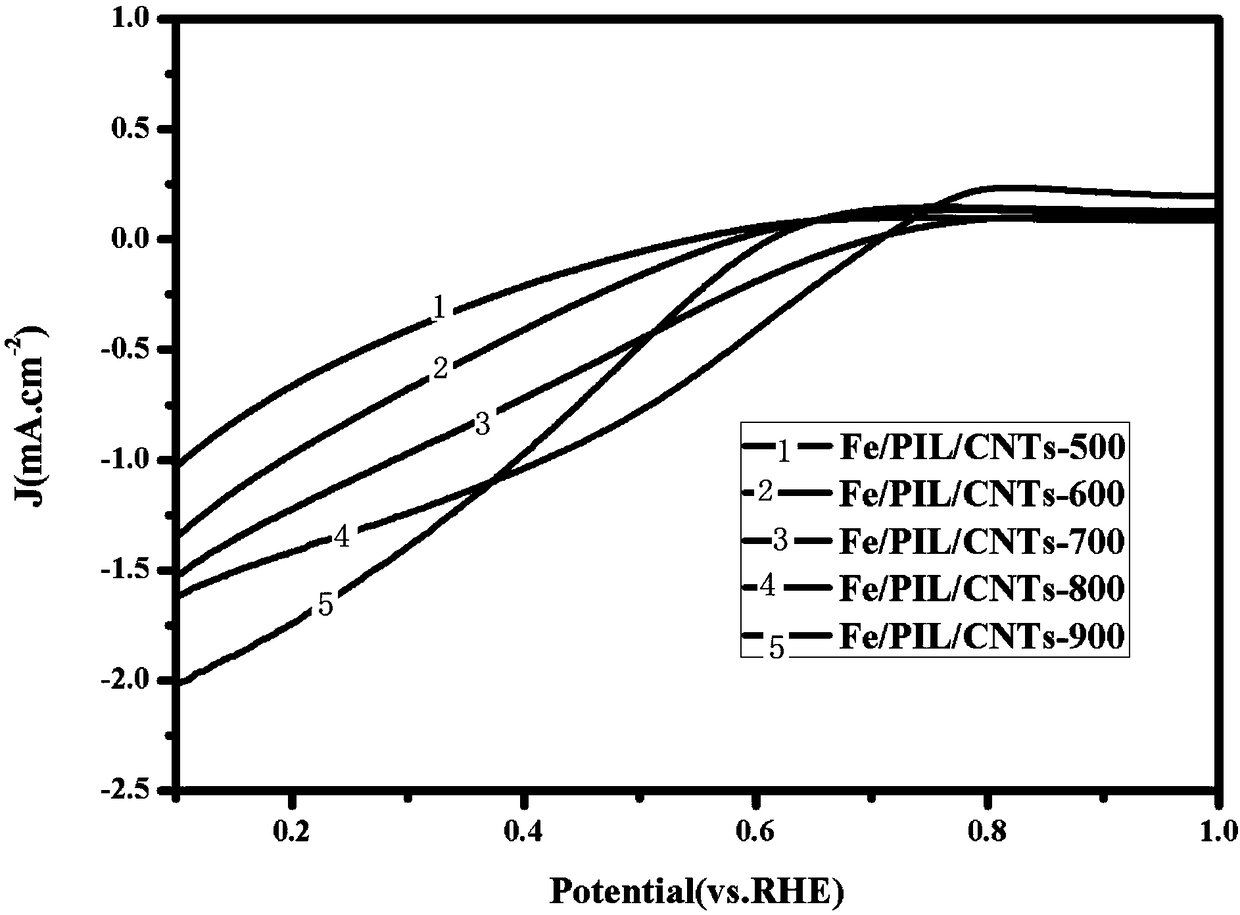

[0037] (5) Put the catalyst precursor in the step (4) into the tube furnace for pyrolysis, and pass N before heating up. 2 Exhaust the air in the tube furnace, then rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com