Environment-friendly waterborne colored steel plate paint and preparing method thereof

A color steel plate and paint paint technology, applied in the field of paint, can solve the problems of high content of volatile organic compounds, adhesion, decrease in hardness, damage to painting workers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

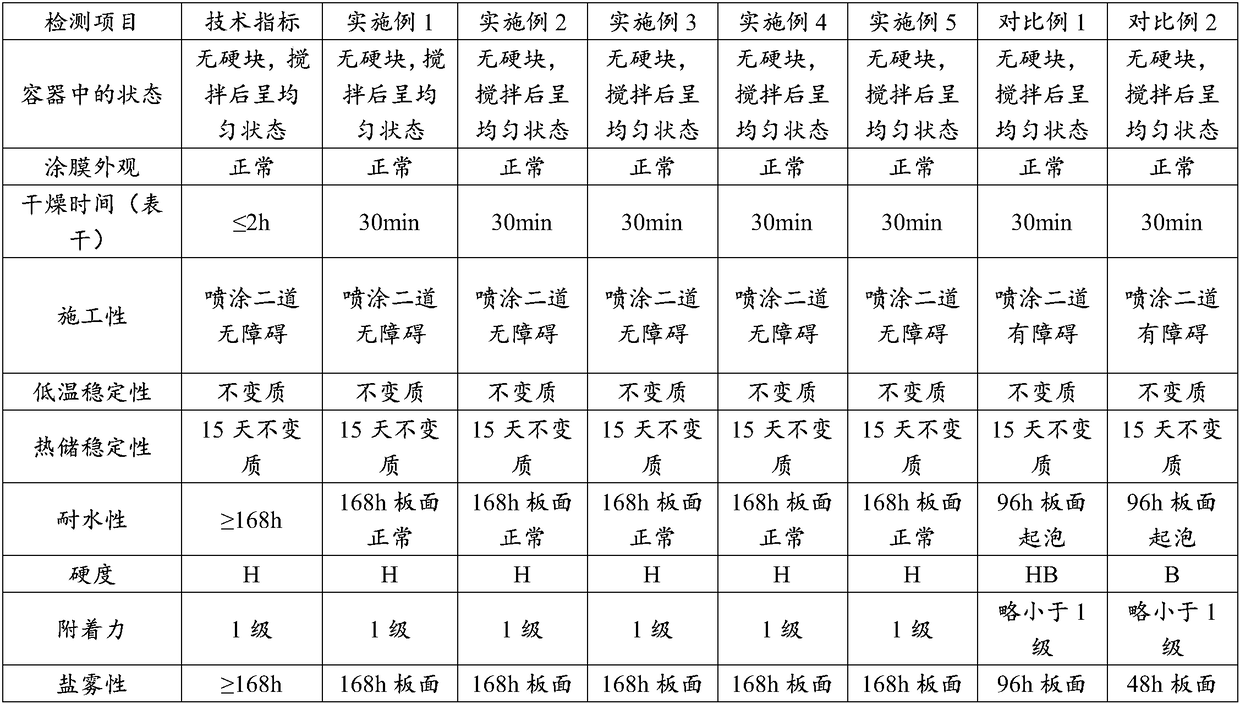

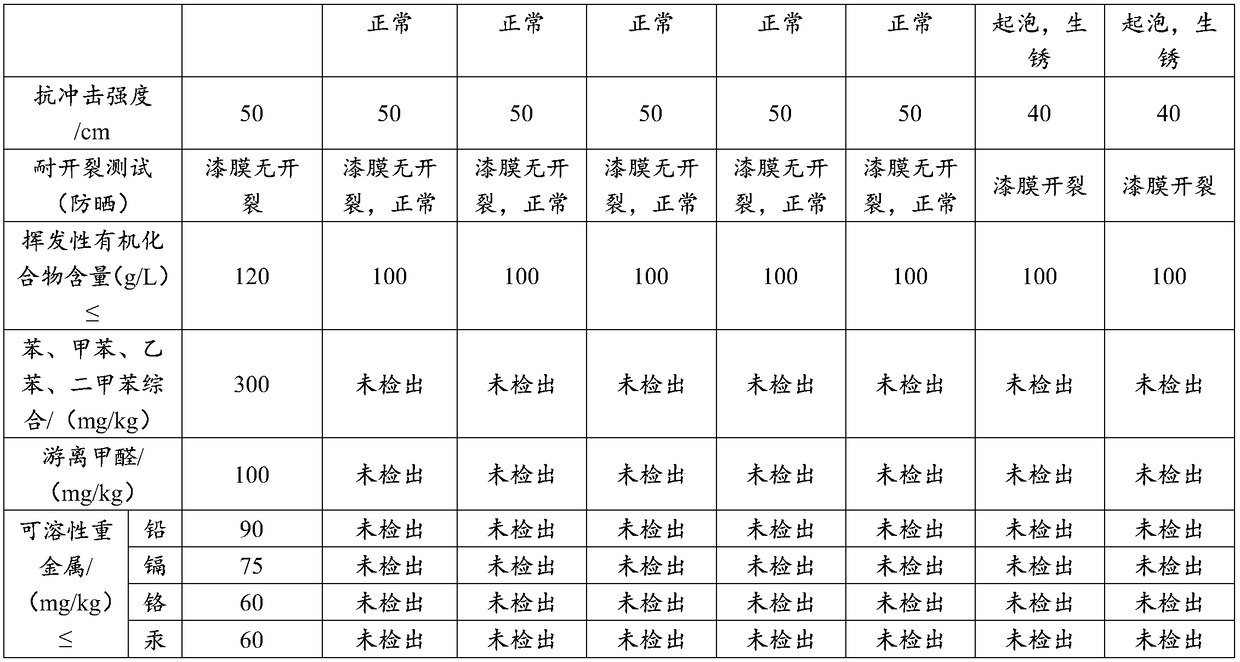

Embodiment 1

[0022] In this embodiment, the environment-friendly water-based paint for color steel plate is composed of the following raw materials in terms of mass percentage:

[0023] Water-based epoxy ester resin GS-5000B is 10.0%; water-based acrylic polymer emulsion 0612 is 55.0%; defoamer Tego-902w is 0.25%; dispersant BYK-190 is 0.5%; neutralizer dimethylethanolamine is 0.88 %; wetting agent BYK-346 is 0.31%; film-forming aid alcohol ester twelve is 4.51%; drier is 0.35%; organic pigment Corfus MH-RC is 2.23%; titanium dioxide R-706 is 0.63% %; compound zinc phosphate is 2.22%; anti-settling thixotropic agent is 4.31%; medium chrome yellow is 0.43%; barium sulfate is 2.43%; anti-flash rust agent ED-617F is 0.63%; thickener Borchi Gel 0620 is 0.32% %; deionized water is 15.0%.

Embodiment 2

[0025] In this embodiment, the environment-friendly water-based paint for color steel plate is composed of the following raw materials in terms of mass percentage:

[0026] Water-based epoxy ester resin GS-5000B is 15.0%; water-based acrylic polymer emulsion 0612 is 32.0%; defoamer BYK-028 is 0.75%; dispersant BYK-194 is 1.25%; neutralizer dimethylethanolamine is 1.1% %; wetting agent BYK-346 is 0.79%; film-forming aid alcohol ester twelve is 6.1%; drier is 0.93%; organic pigment Corfus MH-RC is 2.86%; titanium dioxide R-706 is 1.77% %; compound zinc phosphate is 4.69%; anti-settling thixotropic agent is 5.57%; medium chrome yellow is 1.37%; barium sulfate is 3.27%; anti-flash rust agent ED-617F is 1.67%; %; deionized water is 20.0%.

Embodiment 3

[0028] In this embodiment, the environment-friendly water-based paint for color steel plate is composed of the following raw materials in terms of mass percentage:

[0029] Waterborne epoxy ester resin GS-5000B is 12.0%; waterborne acrylic polymer emulsion 0612 is 48.0%; defoamer Tego-902w is 0.2% and BYK-028 is 0.3%; dispersant BYK-194 is 0.3% and BYK- 190 is 0.4%; neutralizing agent dimethylethanolamine is 1.63%; wetting agent BYK-346 is 0.41%; film-forming aid alcohol ester twelve is 4.51%; drier is 0.45%; MH-RC is 3.4%; titanium dioxide R-706 is 0.9%; composite zinc phosphate is 2.8%; anti-settling thixotropic agent is 4.5%; medium chrome yellow is 0.6%; -617F is 1.4%; thickener BorchiGel 0620 is 0.6%; deionized water is 15.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap