Lithium ion battery anode material and preparation method thereof

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of long cycle, increased cost, and cumbersome material preparation process, and achieve improved performance, small size, and uniform reactant particles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

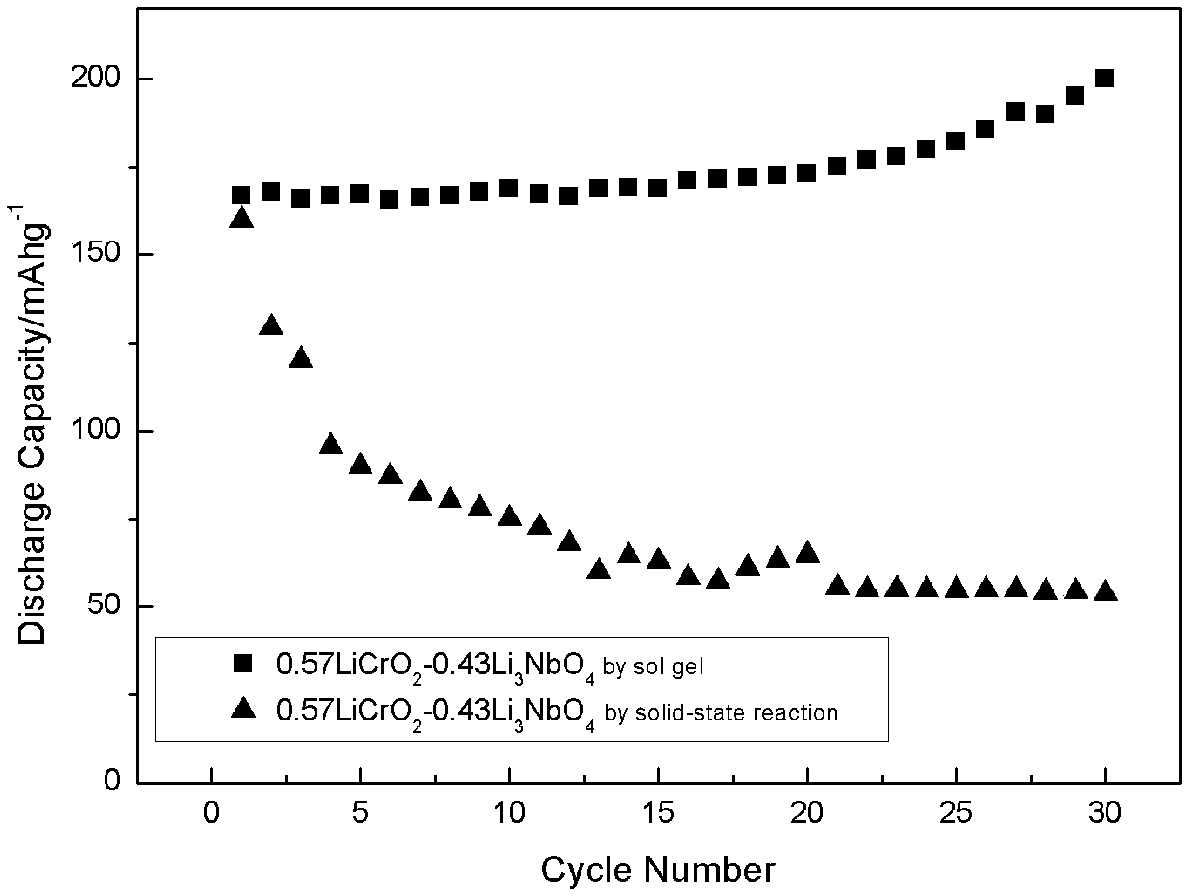

[0062] 0.57LiCrO 2 -0.43Li 3 NbO 4 Preparation of materials: Disperse 0.02mol citric acid (1:1 molar ratio to metal ions) in ionized water to obtain a dispersion; add 0.013mol lithium nitrate, 0.004mol cadmium nitrate, and 0.003mol niobium oxalate to the dispersion, Stir continuously at a stirring speed of 600r / min, stir for 60min until the raw materials are completely dissolved to obtain a uniform solution, adjust the pH to 7.0, add 4.5ml of ethylene glycol (the molar ratio to the metal ion is about 4:1), and stir at 80°C until Gel occurs (stirring speed is 500r / min); Stirring time is 100min;

[0063] The obtained gel was aged for 8 h; then dried and sintered at a low temperature under a nitrogen atmosphere (500° C. for 2 h). The resulting low-temperature sintered product was cooled and pressed into small discs under a pressure of 6Mpa, and then sintered at 950°C for 14 hours in a nitrogen atmosphere to obtain the lithium-ion battery cathode material 0.57LiCrO 2 -0.43Li3N...

Embodiment 2

[0067] 0.57LiCrO 2 -0.43Li 3 NbO 4 Preparation of materials: Disperse citric acid (with a molar ratio of 1:1.5 to metal ions) in ionized water to obtain a dispersion; add 0.013mol lithium nitrate, 0.004mol cadmium nitrate, and 0.003mol niobium oxalate to the dispersion, Stir continuously at a stirring speed of / min, stir for 120min until the raw materials are completely dissolved to obtain a uniform solution, adjust the pH to 8.0, add 5ml of ethylene glycol (the molar ratio to the metal ion is 4.5:1), and stir at 80°C until gel appears ( The stirring speed is 400r / min); the stirring time is 120 min;

[0068] The resulting gel was aged for 10 h; dried, and then sintered at a low temperature under an argon atmosphere (4 h at 450° C.). The resulting low-temperature sintered product was cooled and pressed into 1mm-thick small discs (0.01mol) under a pressure of 7Mpa, and then sintered at 900°C for 8 hours under an argon atmosphere to obtain the lithium-ion battery cathode mater...

Embodiment 3

[0071] Preparation of 0.57LiVO by Sol-Gel Method 2 -0.43Li 3 NbO 4 Materials: Disperse citric acid (with a molar ratio of 1:2 to metal ions) in ionized water at 0.01 to obtain a dispersion; add 0.013mol of lithium acetate, 0.004mol of ammonium metavanadate, and 0.003mol of niobium oxalate to the dispersion. Stir continuously at a stirring speed of 300r / min, stir for 180min until the raw materials are completely dissolved to obtain a homogeneous solution, adjust the pH to 8, add 1g of sucrose, then add 5.6ml of ethylene glycol (the molar ratio to the metal ion is about 5:1), 80°C Stir until gel appears (stirring speed is 600r / min); Stirring time is 90min;

[0072] The obtained gel was aged for 8 hours; then dried, and then sintered at a low temperature under a nitrogen atmosphere (500° C. for 2 hours). The resulting low-temperature sintered product was cooled and pressed into thick discs under a pressure of 7.5Mpa, and then sintered at 950°C for 24 hours under an argon atmos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com