Method for preparing keratin by dissolving wool with deep-eutectic solvent

A low eutectic solvent and keratin technology, applied in the field of keratin preparation, can solve the problems of difficult recycling of waste liquid, environmental pollution, long time and the like, and achieve the effects of low price, high dissolution rate and short preparation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

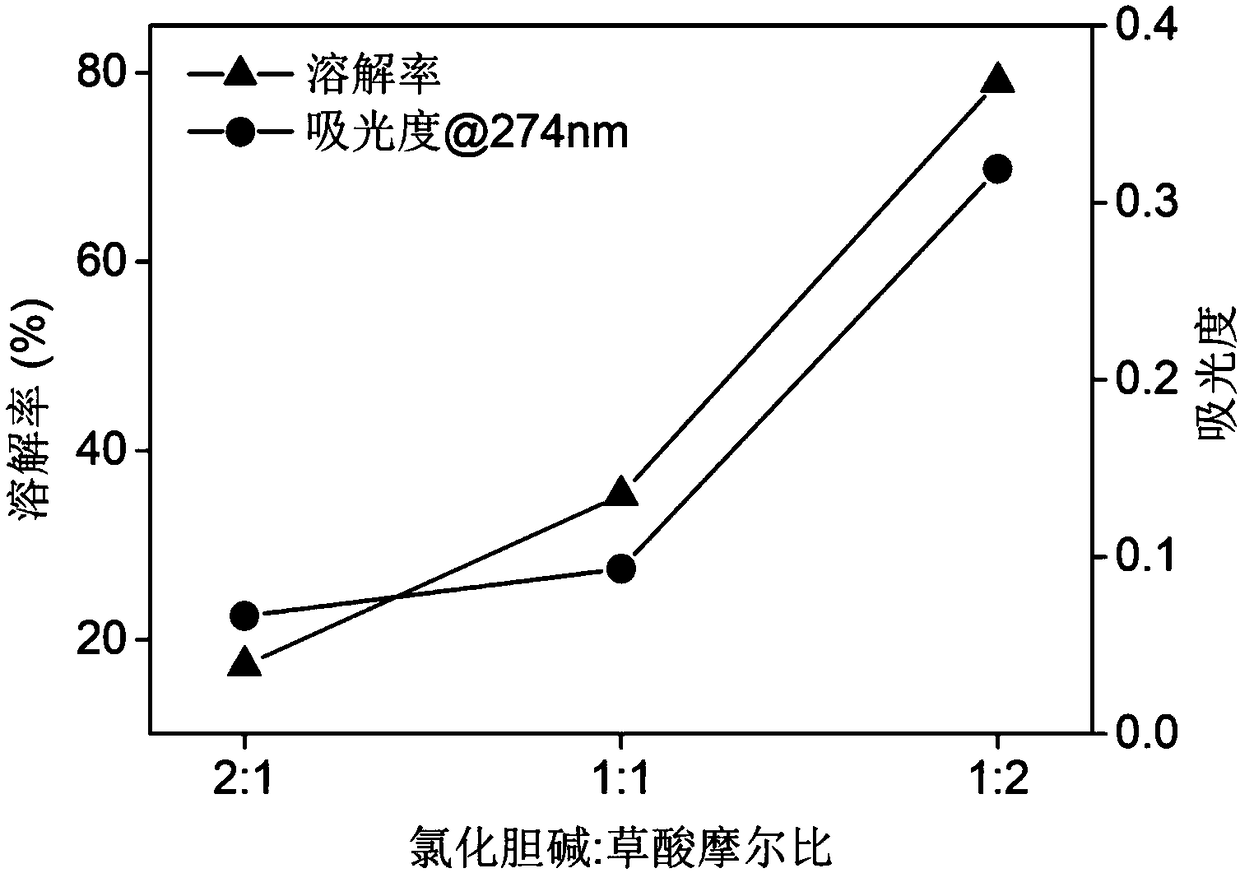

[0031] Weigh choline chloride and oxalic acid, choline chloride and formic acid, choline chloride and citric acid in a molar ratio of 1:2, respectively, and shake them in a constant temperature water bath at 65°C to dissolve them until no A color-transparent solution was generated, and three deep eutectic solvents were prepared. 1% by mass (based on the mass of the deep eutectic solvent) of wool was added to each of the three prepared deep eutectic solvents, and shaken and dissolved in a constant temperature water bath at 95° C. for 2 h. After the dissolution process, the three deep eutectic solvents all produced a yellow-brown suspension, and the deep eutectic solvent combined with choline chloride and oxalic acid dissolved the wool to obtain the darkest suspension, which was yellow-brown.

Embodiment 2

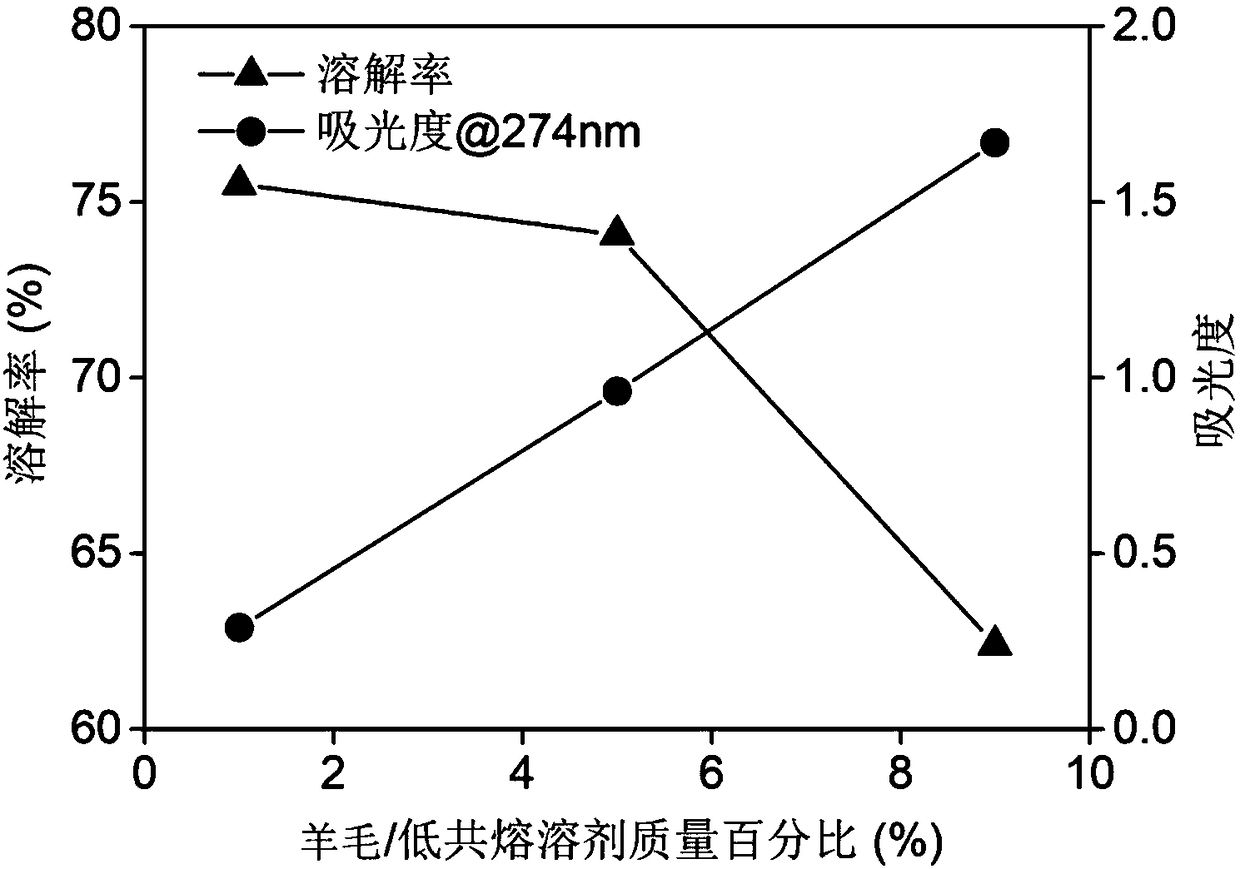

[0033] Weigh a certain mass of choline chloride, oxalic acid, and water according to the molar ratio of 1:2:3, and shake it in a constant temperature water bath at 85°C to dissolve it. After 20 minutes, the solution becomes colorless and transparent, which is eutectic solvent. Add 1% by mass ratio (based on the mass of the deep eutectic solvent) of wool to the prepared deep eutectic solvent, shake and dissolve in a constant temperature water bath at 95° C. for 2 h. After the product obtained was cooled, it was packed into a dialysis bag with a theoretical molecular weight cut-off of 3000 Daltons, dialyzed for 48 hours, filtered, and settled to 25mL, and the absorbance of the solution after the constant volume was tested at 274nm on a UV-visible spectrophotometer. The value is 0.2145. The filter residue was dried to a constant weight and weighed, and the dried filter residue and the mass of wool before dissolution were accurately weighed, and the wool dissolution rate was calc...

Embodiment 3

[0035] Weigh a certain mass of choline chloride and oxalic acid according to the molar ratio of 2:1, and shake it in a constant temperature water bath at 70°C to dissolve it. After 20 minutes, the solution becomes colorless and transparent, which is the deep eutectic solvent. Add 1% by mass ratio (based on the weight of the deep eutectic solvent) of wool to the prepared deep eutectic solvent, shake and dissolve in a constant temperature water bath at 95° C. for 2 hours. After the product obtained was cooled, it was packed into a dialysis bag with a theoretical molecular weight cut-off of 3000 Daltons, dialyzed for 48 hours, filtered, and settled to 100 mL. The absorbance of the solution at 274 nm was measured on a UV-visible spectrophotometer. The value is 0.0667, the filter residue is dried to a constant weight and weighed, and the wool mass before and after dissolution is accurately weighed, and the wool dissolution rate is calculated to be 17.24%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com