Integrated bone-cartilage repair scaffold and preparation method thereof

A cartilage repair and repair layer technology, applied in the direction of prosthesis, medical science, tissue regeneration, etc., can solve the problems of peeling, loss, and difficulty in ensuring long-term integration of cartilage and bone layer, to promote repair, improve cell function, prevent The effect of vascular invasion and cell migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, mercapto-hyaluronic acid (HA-SH) is prepared, and the steps are as follows:

[0035] (1) Dissolve sodium hyaluronate with a molecular weight of 0.3MDa in deionized water, add N-hydroxysuccinimide (NHS), fully dissolve, and then add 1-ethyl-(3-dimethylaminopropyl ) carbodiimide hydrochloride (EDC HCl), fully dissolved, adjust the pH value of the mixture to 4.75 with 1mol / L NaOH solution and 1mol / L HCl solution, react at room temperature for 2h, and then add cysteine Ammonia hydrochloride (CSH·HCl) solution was reacted at room temperature for 24 h, and then the pH value of the reaction solution was adjusted to 8.5 with 1 mol / L NaOH solution, and dithiothreitol (DTT) solution was added to react at room temperature for 12 h.

[0036] In this step, sodium hyaluronate, N-hydroxysuccinimide (NHS), 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC·HCl), semi The molar ratio of cystine hydrochloride (CSH·HCl) to dithiothreitol (DTT) is 1:2:3:2:...

Embodiment 2

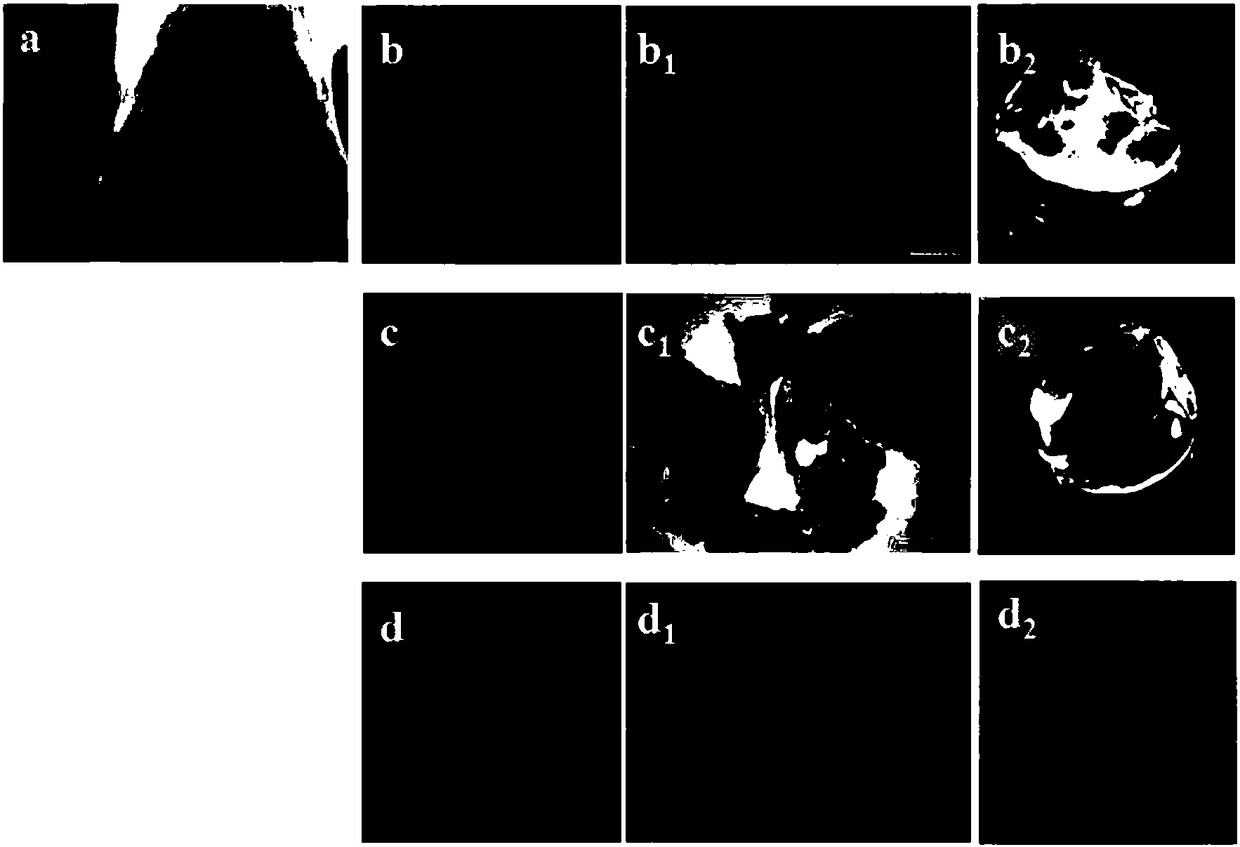

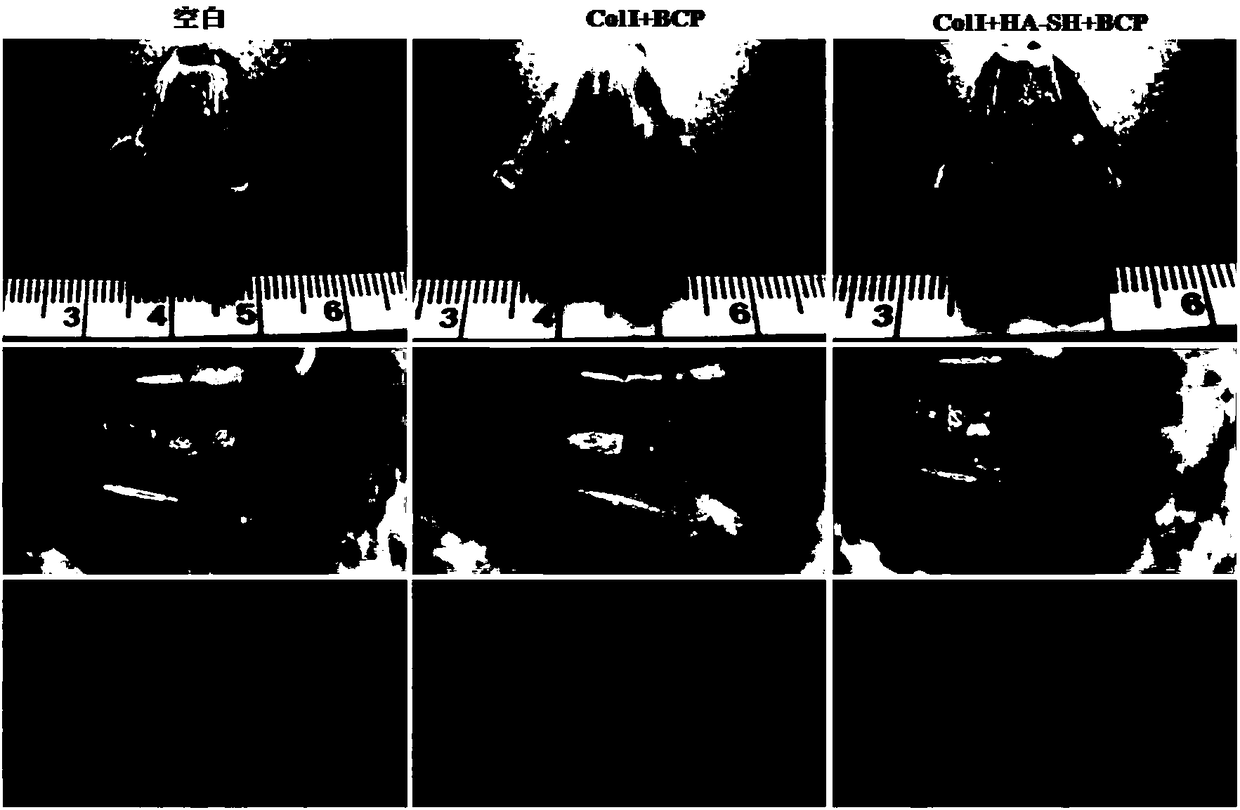

[0040] In this example, a blank integrated bone-cartilage repair scaffold not containing chondrocytes and bone marrow mesenchymal stem cells was prepared, and the steps were as follows:

[0041] (1) Place the formed porous biphasic calcium phosphate ceramics (porous BCP ceramics) in a cylindrical mold with a diameter of 4 mm and a height of 5 mm. The porous BCP ceramics are composed of hydroxyapatite (HA) and β-triphosphate Composed of calcium (β-TCP), the mass ratio of HA to β-TCP is 2:8, and the porosity is about 70%. The formed porous BCP ceramic is a cylindrical block with a diameter of 4mm and a height of 2mm. The formed porous BCP ceramic It is placed on the closed end of the cylindrical mould, coaxially with the mould.

[0042] (2) Dissolve the HA-SH prepared in Example 1 with α-MEM medium, adjust the pH value to 7.2~7.4 with 1mol / L NaOH solution under ice bath, obtain 3.0wt% HA-SH solution, and immediately The HA-SH solution is injected above the shaped porous BCP cer...

Embodiment 3

[0045] In this example, to prepare an integrated bone-cartilage repair scaffold, the steps are as follows:

[0046] (1) Place the formed porous BCP ceramics in a cylindrical mold with a diameter of 4 mm and a height of 5 mm. The porous BCP ceramics are composed of HA and β-TCP, and the mass ratio of HA to β-TCP is 2:8. The porosity is about 70%. The shaped porous BCP ceramics is a cylindrical block with a diameter of 4 mm and a height of 2 mm. The shaped porous BCP ceramics are placed on the closed end of the cylindrical mold coaxially with the mold.

[0047] (2) Dissolve the HA-SH prepared in Example 1 with α-MEM medium, adjust the pH value to 7.2-7.4 with 1mol / L NaOH solution under ice bath, add Nile red dye and mix well to obtain HA-SH Concentration of 3.0wt% HA-SH-dye mixed solution, the HA-SH-dye mixed solution was injected immediately above the molded porous BCP ceramics in the mold, after the HA-SH-dye mixed solution was injected into the mold, part of the HA- The SH-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com