Preparation method of Bi-Bi3NbO7 composite photocatalyst and Bi-Bi3NbO7 composite photocatalyst

A technology of bi-bi3nbo7 and composite light, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems affecting the stability of the catalytic process, and improve the visible light photocatalytic degradation activity and operation Simple, easy to prepare and safe results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

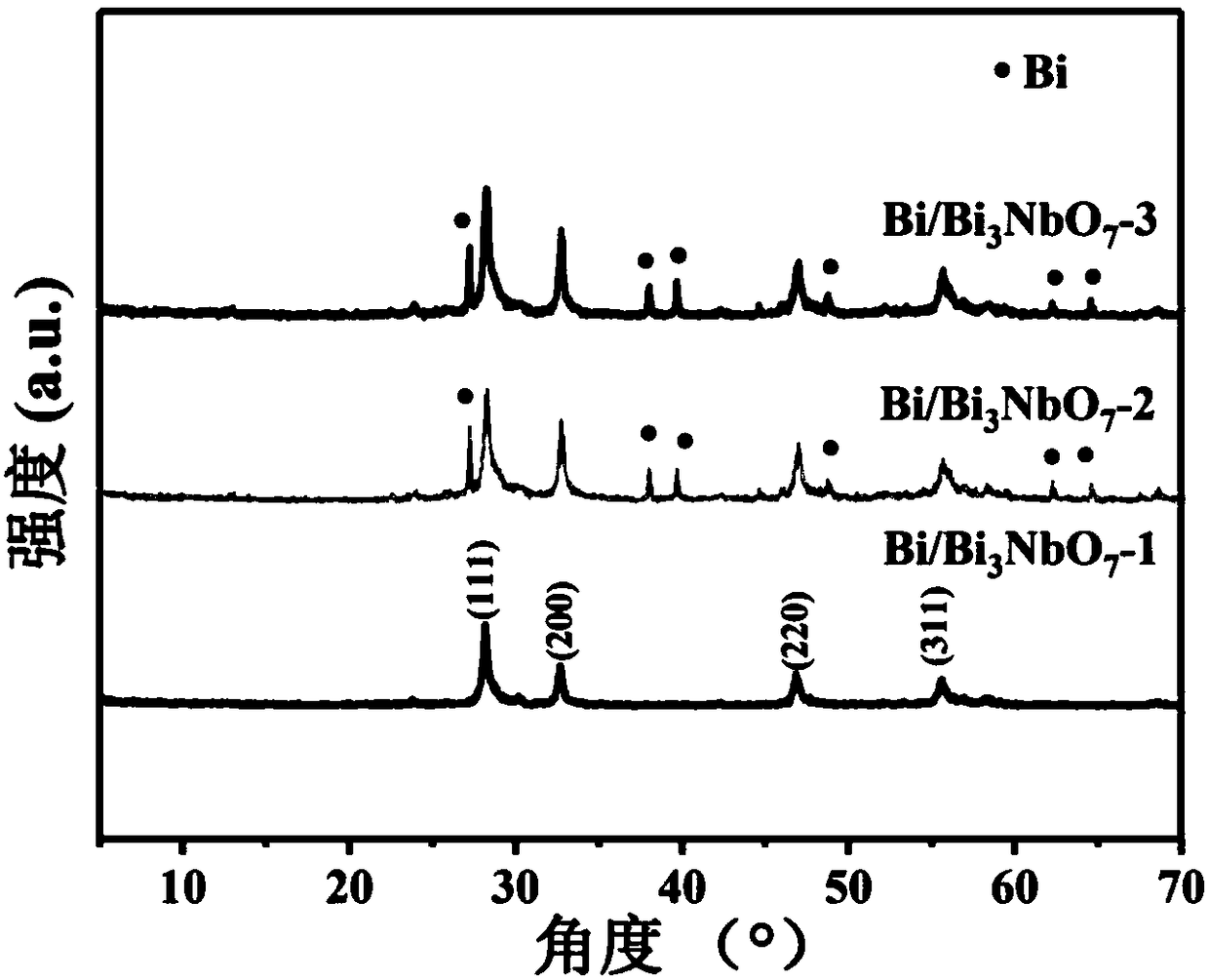

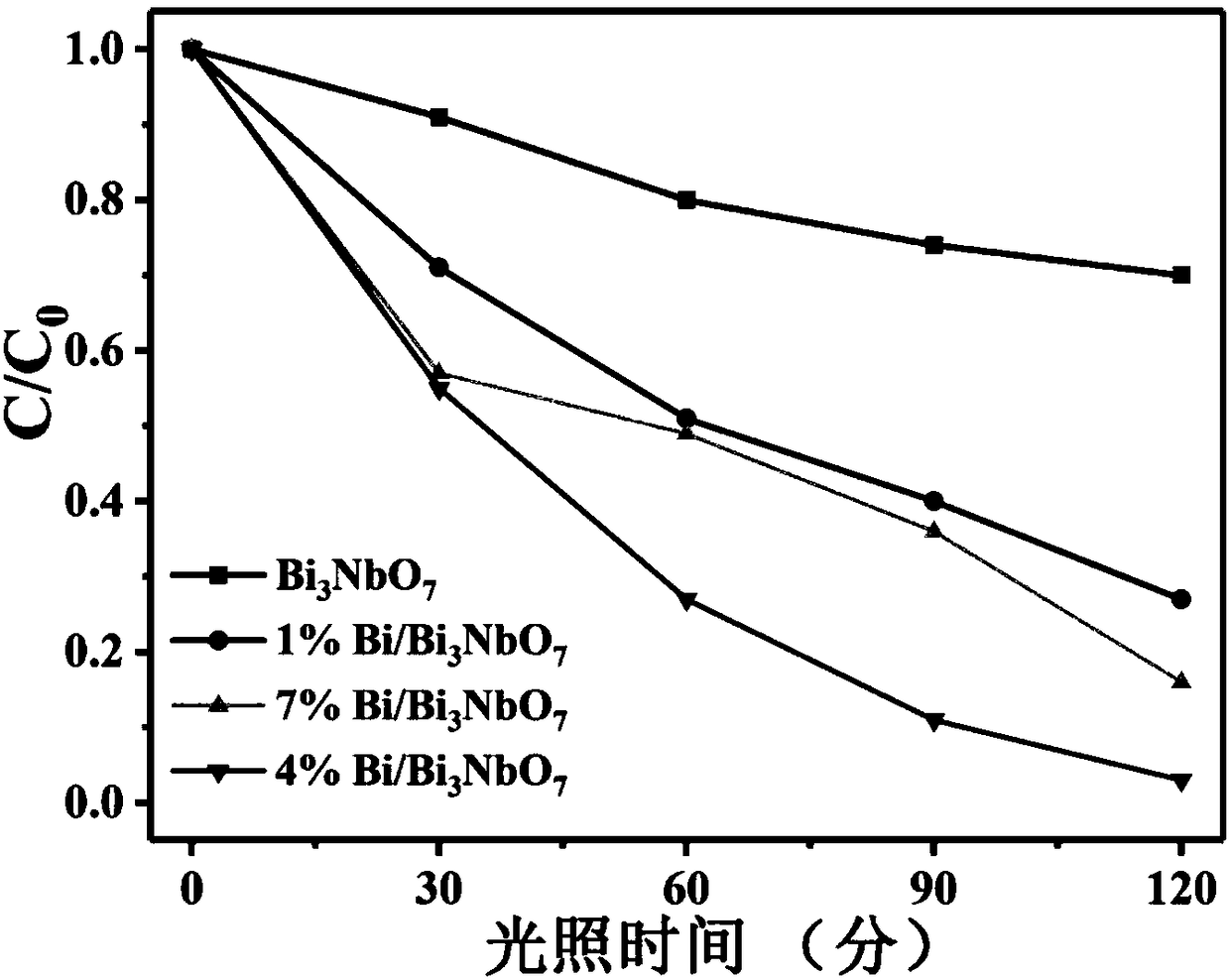

[0027] A Bi-Bi 3 NbO 7 The preparation method of the composite photocatalyst includes the following steps:

[0028] S01: Weigh bismuth nitrate pentahydrate and niobium oxalate at a molar ratio of 3:1, and dissolve the weighed bismuth nitrate pentahydrate and niobium oxalate in a 1:4 volume ratio of glacial acetic acid and methanol mixed solution, fully Stir to obtain the first mixed solution;

[0029] S02: Slowly add benzyl alcohol to the first mixed solution, and stir thoroughly to obtain a second mixed solution;

[0030] S03: Add potassium hydroxide solution to the second mixed solution, adjust the PH value of the second mixed solution to about 13, and then conduct a hydrothermal reaction at 180°C for 24 hours, and separate a pale yellow precipitate after cooling Thing

[0031] S04: Wash and dry the light yellow precipitate to obtain Bi 3 NbO 7 Nanosheets;

[0032] S05: Put the Bi 3 NbO 7 Nanosheets are dispersed in ethylene glycol solution, an appropriate amount of bismuth source i...

Embodiment 1

[0046] Example One, a Bi-Bi 3 NbO 7 The preparation method of the composite photocatalyst includes the following steps:

[0047] S01: Weigh bismuth nitrate pentahydrate and niobium oxalate in a molar ratio of 3:1, and dissolve the weighed bismuth nitrate pentahydrate and niobium oxalate in 50ml of a 1:4 volume ratio of glacial acetic acid and methanol mixed solution, Stir fully to obtain the first mixed solution;

[0048] The mixed solution of 50ml glacial acetic acid and methanol contains 10ml glacial acetic acid and 40ml methanol;

[0049] S02: Slowly add 20 ml of benzyl alcohol to the first mixed solution, and stir thoroughly to obtain a second mixed solution;

[0050] S03: Add 7mol / L potassium hydroxide solution to the second mixed solution, adjust the pH of the second mixed solution to 13, and then conduct a hydrothermal reaction at 180°C for 24h, and separate after cooling Light yellow precipitate;

[0051] S04: Wash and dry the light yellow precipitate to obtain Bi 3 NbO 7 Nano...

Embodiment 2

[0057] Embodiment two, a Bi-Bi 3 NbO 7 The preparation method of the composite photocatalyst includes the following steps:

[0058] S01: Weigh bismuth nitrate pentahydrate and niobium oxalate in a molar ratio of 3:1, and dissolve the weighed bismuth nitrate pentahydrate and niobium oxalate in 50ml of a 1:4 volume ratio of glacial acetic acid and methanol mixed solution, Stir fully to obtain the first mixed solution;

[0059] The mixed solution of 50ml glacial acetic acid and methanol contains 10ml glacial acetic acid and 40ml methanol;

[0060] S02: Slowly add 20 ml of benzyl alcohol to the first mixed solution, and stir thoroughly to obtain a second mixed solution;

[0061] S03: Add 7mol / L potassium hydroxide solution to the second mixed solution, adjust the pH of the second mixed solution to 13, and then conduct a hydrothermal reaction at 180°C for 24h, and separate after cooling Light yellow precipitate;

[0062] S04: Wash and dry the light yellow precipitate to obtain Bi 3 NbO 7 N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com