A kind of preparation method of multiphase titanium diboride/titanium carbonitride-stainless steel cermet hot rolling mill roll ring

A cermet and titanium carbonitride technology, which is applied in the field of preparation of multiphase titanium diboride/titanium carbonitride-stainless steel cermet hot rolling mill roll rings, can solve the problems of high brittleness, low material hardness and grain size. Coarse and other problems, to achieve the effect of high density, simple composition and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

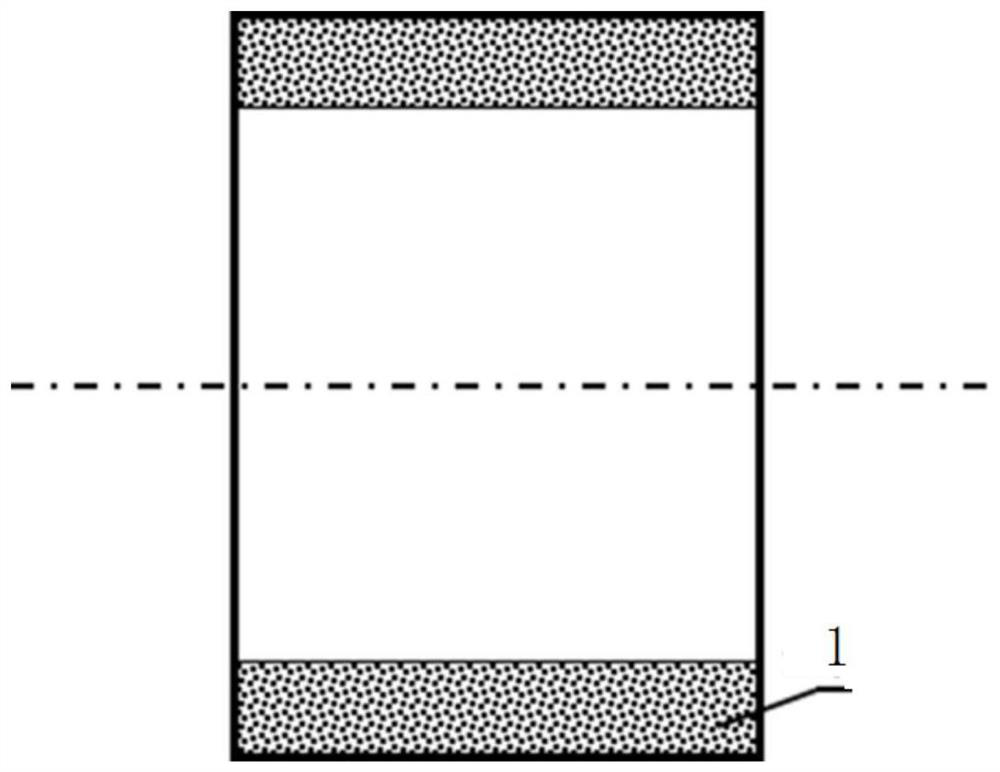

[0030] A multiphase TiB 2 The preparation method of / Ti(C,N)-stainless steel cermet hot-rolled roll ring, the preparation sequence includes the steps of mixing materials, wet grinding, drying, molding, vacuum solid phase sintering, machining, and high temperature liquid phase sintering, as follows:

[0031] (1) Mixing material: select commercially available TiB with a purity of not less than 99% 2 , Ti(C,N) (titanium carbonitride), Fe, Ni, Cr, Mn, Si and C powder mixed, each component according to mass percentage is TiB 2 : 1%, Ti(C,N): 74%, Fe: 17.965%, Ni: 2.25%, Cr: 4.5%, Mn: 0.2125%, Si: 0.055% and C: 0.0175%;

[0032] (2) Ball milling: Put the mixed raw materials into a ball milling tank, add 2% absolute ethanol as a medium, vacuumize the ball milling tank and fill it with argon, the mass ratio of balls to materials is 10:1 , the ball milling speed is 300r / min, and the ball milling time is 20h;

[0033] (3) Drying: Put the ball-milled slurry in a rotary evaporator, fir...

Embodiment 2

[0041] a TiB 2 The preparation method of / Ti(C,N)-stainless steel cermet hot-rolled roll ring, the preparation sequence includes the steps of mixing materials, wet grinding, drying, molding, vacuum solid phase sintering, machining, and high temperature liquid phase sintering, as follows:

[0042] (1) Mixing material: select TiB with a purity of not less than 99% 2 , Ti(C,N), Fe, Ni, Cr, Mn, Si and C powder mixed, each component is TiB according to mass percentage 2 : 5%, Ti(C,N): 70%, Fe: 17.965%, Ni: 2.25%, Cr: 4.5%, Mn: 0.2125%, Si: 0.055% and C: 0.0175%;

[0043] (2) Ball milling: Put the mixed raw materials into a ball milling tank, add 2% absolute ethanol as a medium, vacuumize the ball milling tank and fill it with argon, the mass ratio of balls to materials is 10:1 , the ball milling speed is 300r / min, and the ball milling time is 10h;

[0044] (3) Drying: Put the ball-milled slurry in a rotary evaporator, first vacuum, the air pressure drops to 0.09MPa and starts to...

Embodiment 3

[0051] a TiB 2 The preparation method of / Ti(C,N)-stainless steel cermet hot-rolled roll ring, the preparation sequence includes the steps of mixing materials, wet grinding, drying, molding, vacuum solid phase sintering, machining, and high temperature liquid phase sintering, as follows:

[0052] (1) Mixing step: select TiB with a purity of not less than 99% 2 , Ti(C,N), Fe, Ni, Cr, Mn, Si and C powder mixed, each component is TiB according to mass percentage 2 : 10%, Ti(C,N): 65%, Fe: 17.965%, Ni: 2.25%, Cr: 4.5%, Mn: 0.2125%, Si: 0.055% and C: 0.0175%;

[0053] (2) Ball milling step: put the mixed raw materials into a ball mill jar, add 2% absolute ethanol as a medium, vacuumize the ball mill jar and fill it with argon, the mass ratio of balls to material is 10: 1. The ball milling speed is 300r / min, and the ball milling time is 10h;

[0054] (3) Drying step: put the ball-milled slurry in a rotary evaporator, first vacuum, the air pressure drops to 0.09MPa and starts to h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com