Field emission self-focusing pulsed X-ray generator with integrated high-voltage power supply

A technology of generating device and high-voltage power supply, which is applied in X-ray tubes, X-ray tube electrodes, X-ray tube components, etc., can solve problems such as poor focusing performance, poor reliability, and complicated circuits, and improve safety and reliability. performance, size and weight reduction, and high boosting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

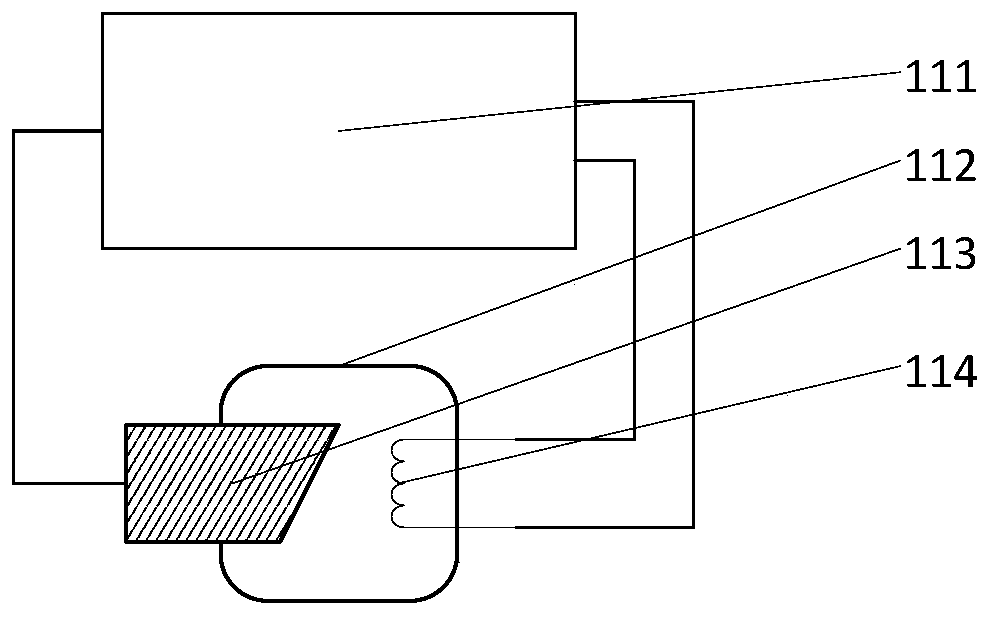

[0040] The schematic circuit diagram and structure section diagram of Embodiment 1 are shown in figure 2 with image 3middle. The components in this embodiment include a low-voltage power supply and control circuit 201, a glass vacuum chamber 202, an anode 203 of the X-ray generating part, a cathode 204 of the X-ray generating part based on field emission, a transformer primary coil 211, a transformer secondary coil 212, a circle A cylindrical transformer core 213 , a rectifier diode 214 and a coupling capacitor 215 .

[0041] The whole device is powered by a low-voltage DC power supply of 12 to 24 volts or a battery, and the low-voltage power supply and the control circuit 201 generate a high-frequency signal equal to the resonant frequency of the transformer, which is 72 kHz in this embodiment. Inside the low-voltage power supply and control circuit 201, the high-frequency signal passes through the H-shaped full-bridge circuit composed of semiconductor field effect transi...

Embodiment 2

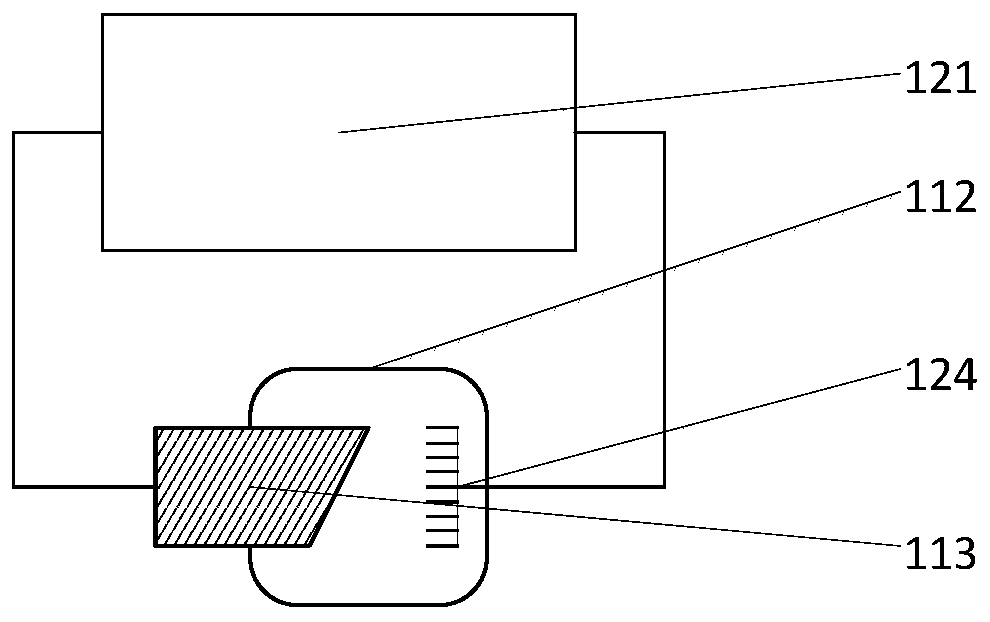

[0047] Embodiment 2 adopts the same overall structure as Embodiment 1.

[0048] In this embodiment, the rectifier diode 214 and coupling capacitor 215 in Embodiment 1 are replaced by a voltage multiplication coupling circuit 520 (shown in Figure 5 ). The voltage doubling circuit can multiply the output voltage value of the high-voltage generator, and can increase the energy of X-rays to more than 100 kV for applications requiring higher energy.

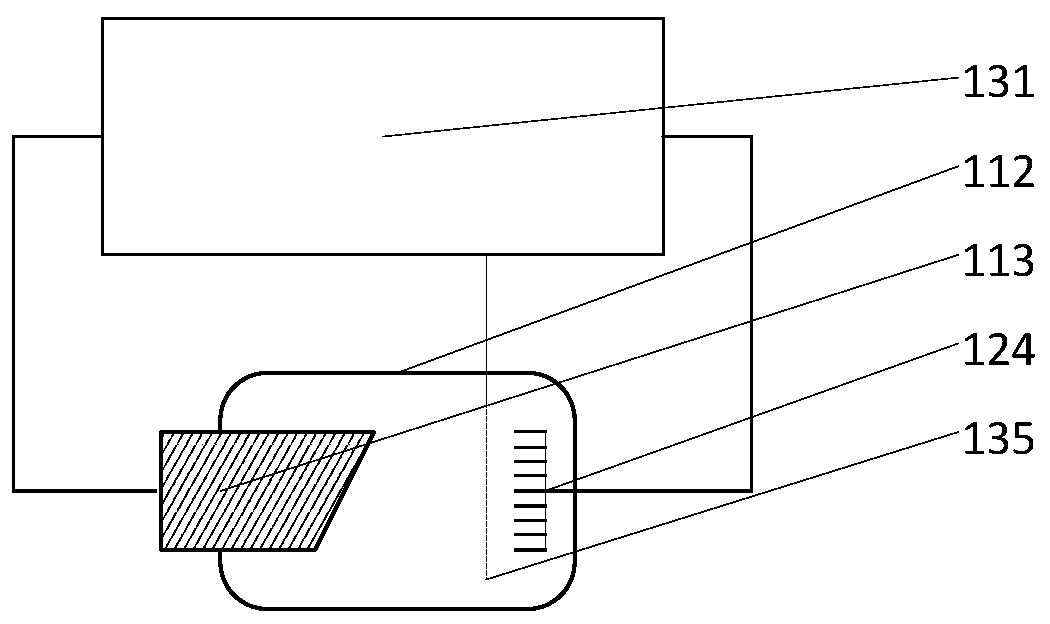

[0049] In this embodiment, the anode 203 of the X-ray generation part in Embodiment 1 is formed by the anode 614 of the pointed X-ray generation part (shown in Image 6 ). The tapered anode can better focus the electron beam, resulting in a smaller focal spot and improving image resolution.

[0050] In this embodiment, the cylindrical transformer core 213 in Embodiment 1 is replaced by a pot-shaped transformer core 613 (shown in Image 6 and Figure 7 ). The pot-shaped magnetic core can reduce magnetic flux leakage and improve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com