Method for preparing perovskite solar cell by steam assistance

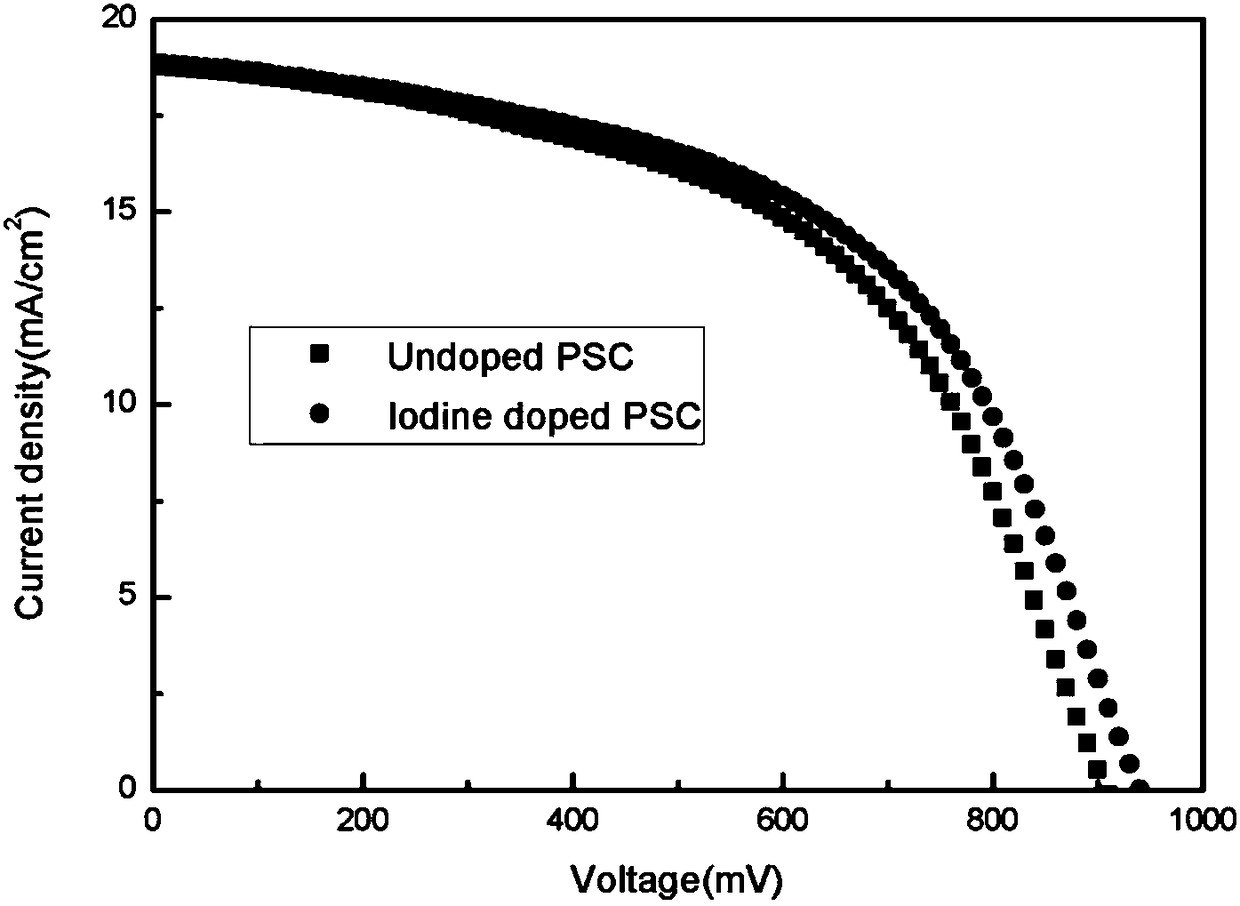

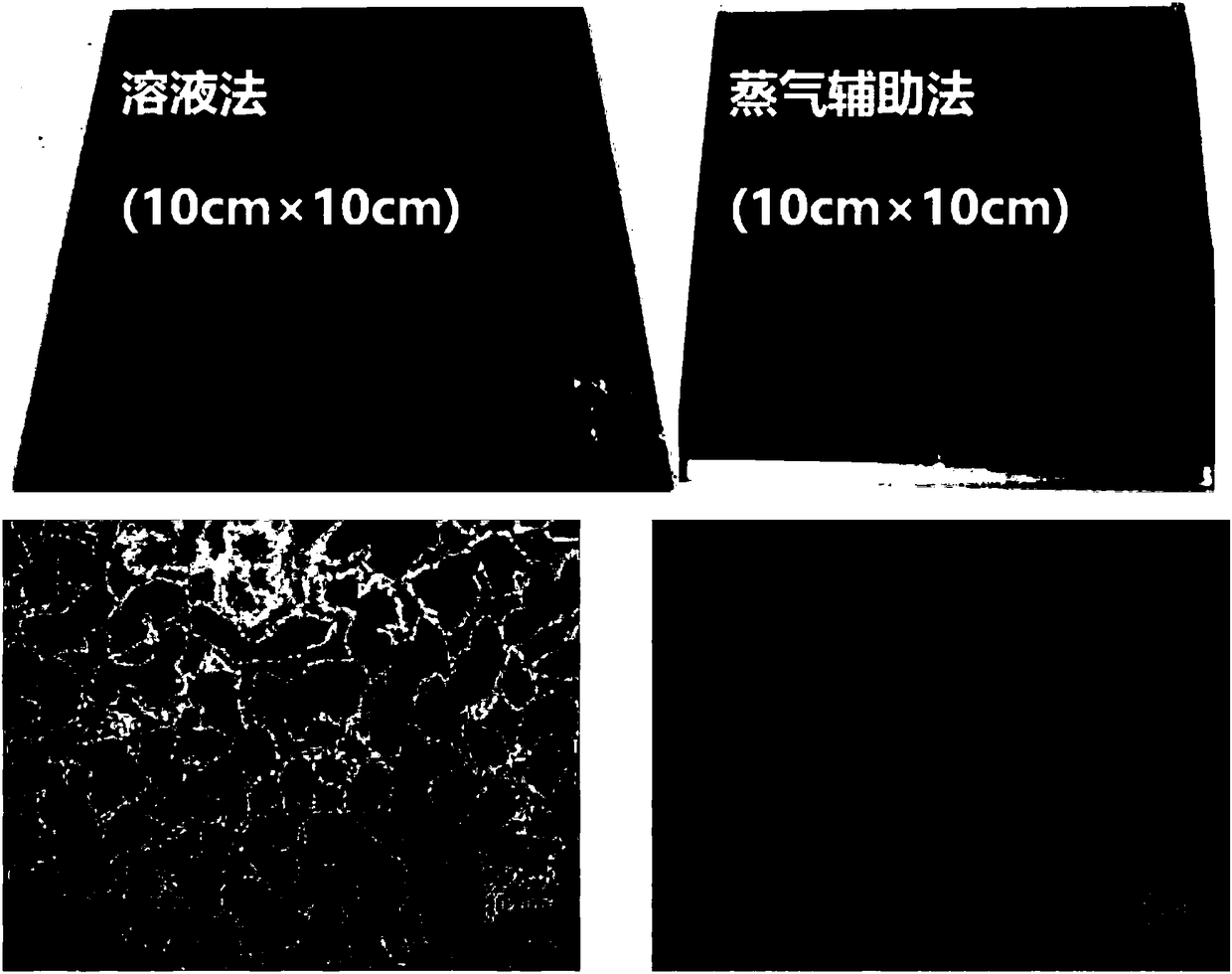

A solar cell and perovskite technology, applied in the field of solar cells, can solve problems such as poor thermal stability, inability to prepare large-sized films, rough and porous films, etc., and achieve the effects of improving photoelectric conversion efficiency, good commercial prospects, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for vapor-assisted preparation of perovskite solar cells, comprising the steps of:

[0025] 1) Take a piece of clean ITO conductive glass and use laser etching; after ultrasonic cleaning with soapy water, pure water and ethanol for 10 minutes, blow dry with nitrogen gas to obtain a conductive glass substrate;

[0026] 2) Evaporate C on the conductive glass substrate after UV irradiation 60 As an electron transport layer, the evaporation rate The thickness is 10nm;

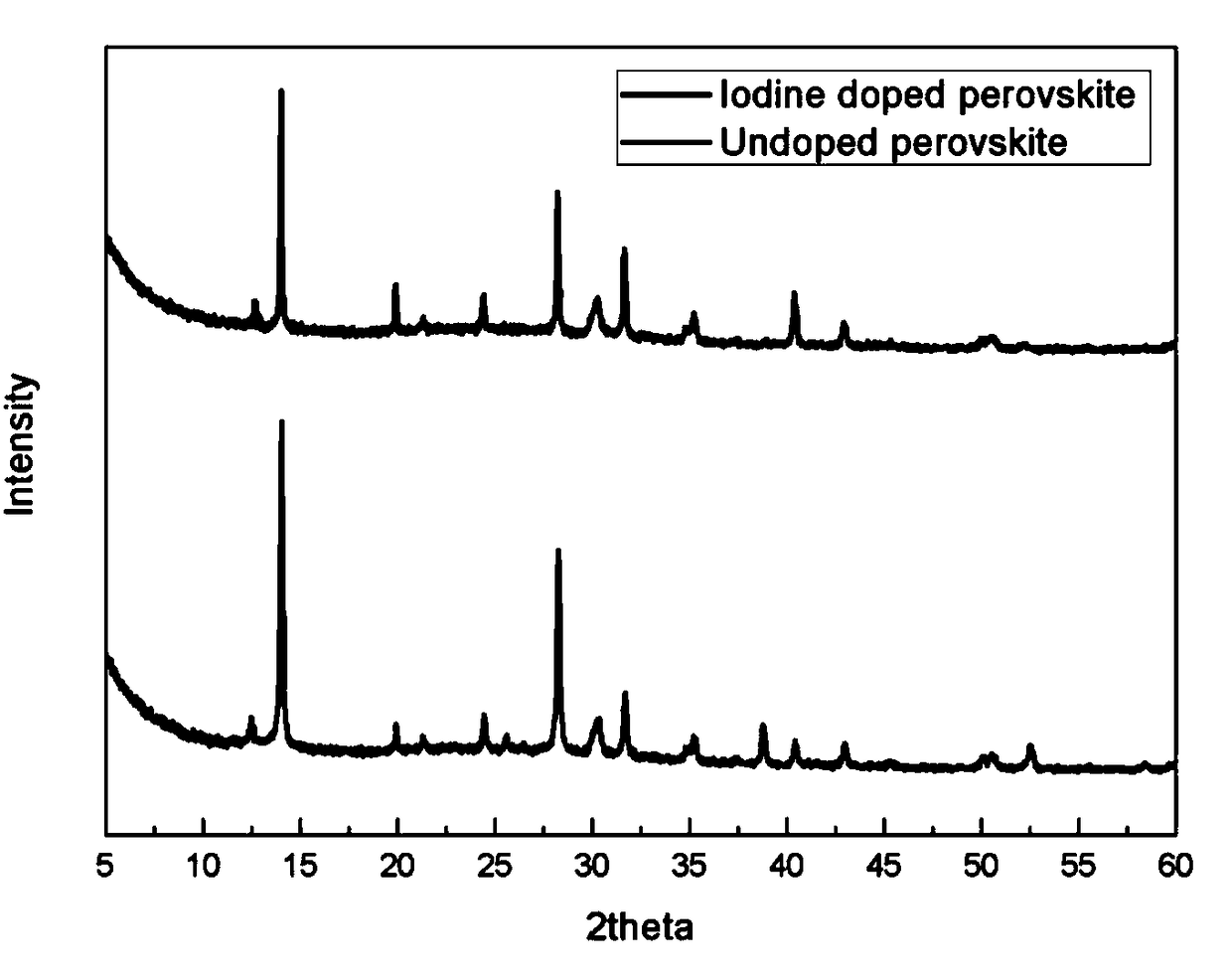

[0027] 3) Evaporation of PbI on a conductive substrate with an electron transport layer 2 Layer with a thickness of 165nm, for later use; add 0.5gFAI and 0.00762g iodine element (concentration is about 3mmol / L) to 10ml isopropanol and stir to obtain a precursor solution, and then use a spray gun to spray it on another piece with a small air volume Formation of FAI / I on ordinary glass 2 layer, spare; the PbI 2 Layers and FAI / I 2 The layers are placed opposite each other with a distance of 3 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com