Preparation method of yellow serofluid (generated during making bean curds) milk -promoting glycolysis soybean meal

A technology of yellow pulp water and soybean meal, which is applied in the fields of feed, enzyme preparations and microorganisms, can solve the problems of poor effect of sow promoting/promoting lactation feed, insufficient secondary utilization of yellow pulp water, waste of food resources, etc., and achieve the benefit of intestinal tract Unobstructed and protected, improved survival rate and weaning weight, easy to digest and absorb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of yellow pulp water promoting lactolysis fermented soybean meal, comprising the following steps:

[0044] Pump 820kg of yellow pulp water into a three-effect concentration evaporator, and evaporate and concentrate to 300kg (solid content: 33%) under the condition of 55-60°C. After mixing 100kg of soybean meal powder, 8kg of glucose and 300kg of yellow pulp water concentrate and adjusting the slurry, add lye or calcium carbonate to adjust the initial pH to 6.5, insert 8kg of Bacillus subtilis seed solution producing cellulase and protease and 3kg of Saccharomyces cerevisiae seed liquid was subjected to aerobic fermentation at 30°C for 30 hours to obtain 407kg of oxygen-consuming yellow syrup water-fermented soybean meal (fermentation loss of 12kg).

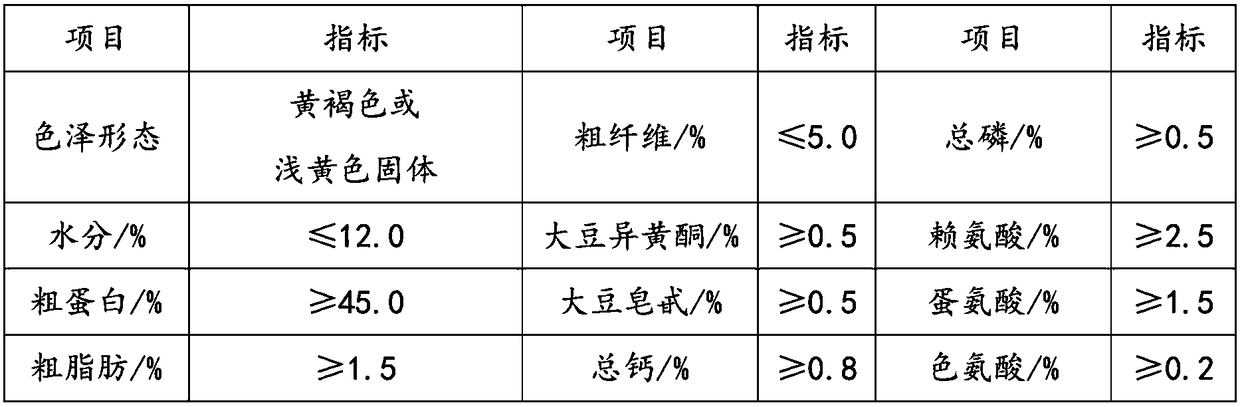

[0045] Stir and mix 0.5kg of cellulase, 0.05kg of pectinase, 0.05kg of protease, and 10kg of lactic acid bacteria seed solution into 407kg of oxygen-consuming yellow pulp fermented soybean meal, and per...

Embodiment 2

[0051] A preparation method for lactating sow yellow pulp water promoting lactolysis fermented soybean meal, comprising the following steps:

[0052] Pump 3800kg of yellow pulp water into a three-effect concentration evaporator, and evaporate and concentrate to 650kg (solid content: 30%) under the condition of 60-65°C. After mixing 200kg of soybean meal powder, 20kg of glucose and 650kg of yellow pulp water concentrate and adjusting the slurry, add lye or calcium carbonate to adjust the initial pH to 7, insert 20kg of Bacillus subtilis seed solution producing cellulase and protease and 4kg of Saccharomyces cerevisiae seed liquid was subjected to aerobic fermentation at 32°C for 36 hours to obtain 870kg of oxygen-consuming yellow syrup water-fermented soybean meal (fermentation loss of 24kg).

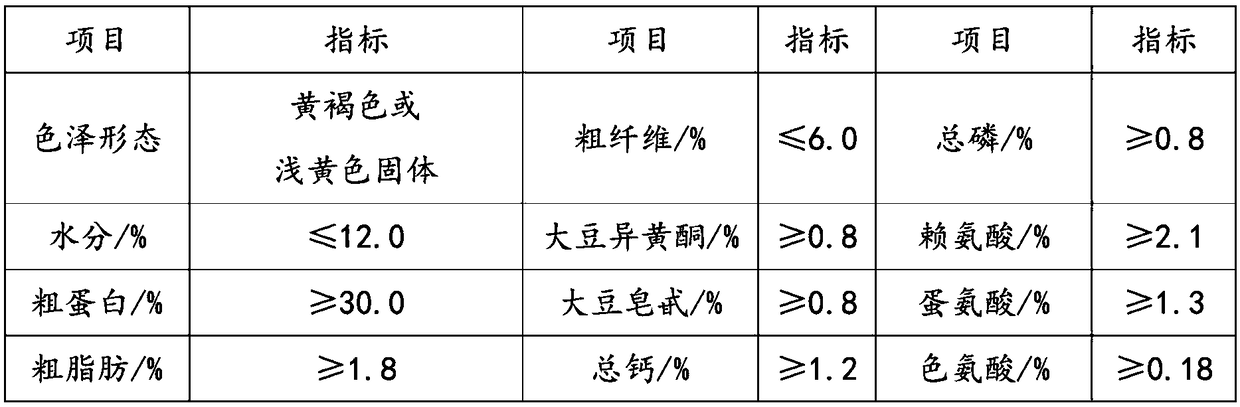

[0053] Stir and mix 1.5kg of cellulase, 0.25kg of pectinase, 0.1kg of protease, and 18kg of lactic acid bacteria seed solution into 870kg of oxygen-consuming yellow pulp fermented soybea...

Embodiment 3

[0059] A preparation method for lactating sow yellow pulp water promoting lactolysis fermented soybean meal, comprising the following steps:

[0060] 1170kg of yellow pulp water is pumped into a three-effect concentrated evaporator, and the yellow pulp water is evaporated and concentrated to 260kg (solid content is 90%) at 40-50°C. Mix 1300kg of soybean meal powder, 3kg of glucose and 2600kg of yellow pulp water concentrate and adjust the slurry, add lye or calcium carbonate to adjust the initial pH to 4, insert 31kg of Bacillus subtilis seed solution producing cellulase and protease and 12kg of Saccharomyces cerevisiae seed liquid was subjected to aerobic fermentation at 10°C for 240 hours to obtain 1559kg of oxygen-consuming yellow syrup water-fermented soybean meal (47kg of fermentation loss).

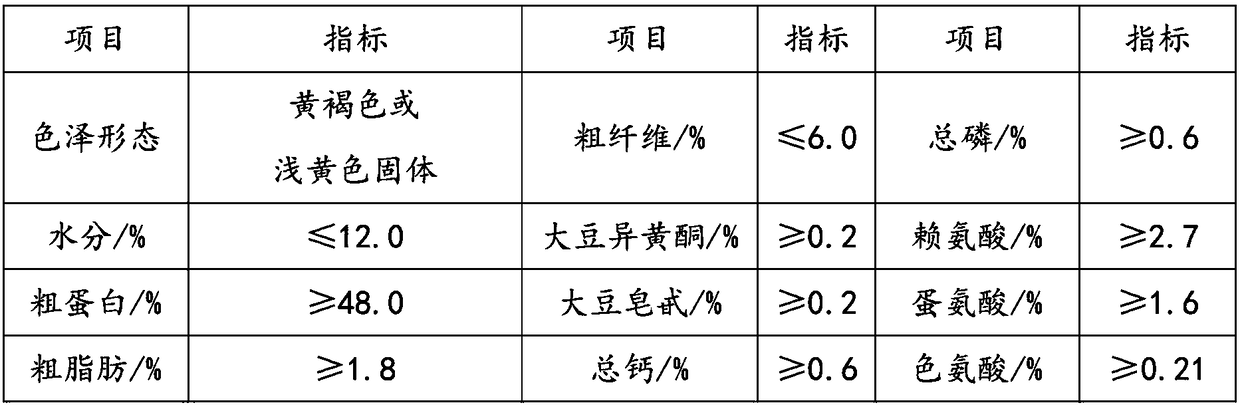

[0061] Stir and mix 2.5kg of cellulase, 0.5kg of pectinase, 0.1kg of protease, and 31kg of lactic acid bacteria seed solution into 1,559kg of oxygen-consuming yellow pulp fermented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com