Molybdenum disulfide nano-sheet in-situ modified biological ceramic stent, preparation method and applications thereof

A molybdenum disulfide, in-situ modification technology, used in pharmaceutical formulations, tissue regeneration, medical preparations containing active ingredients, etc., can solve problems such as difficult self-healing of the body and tissue defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

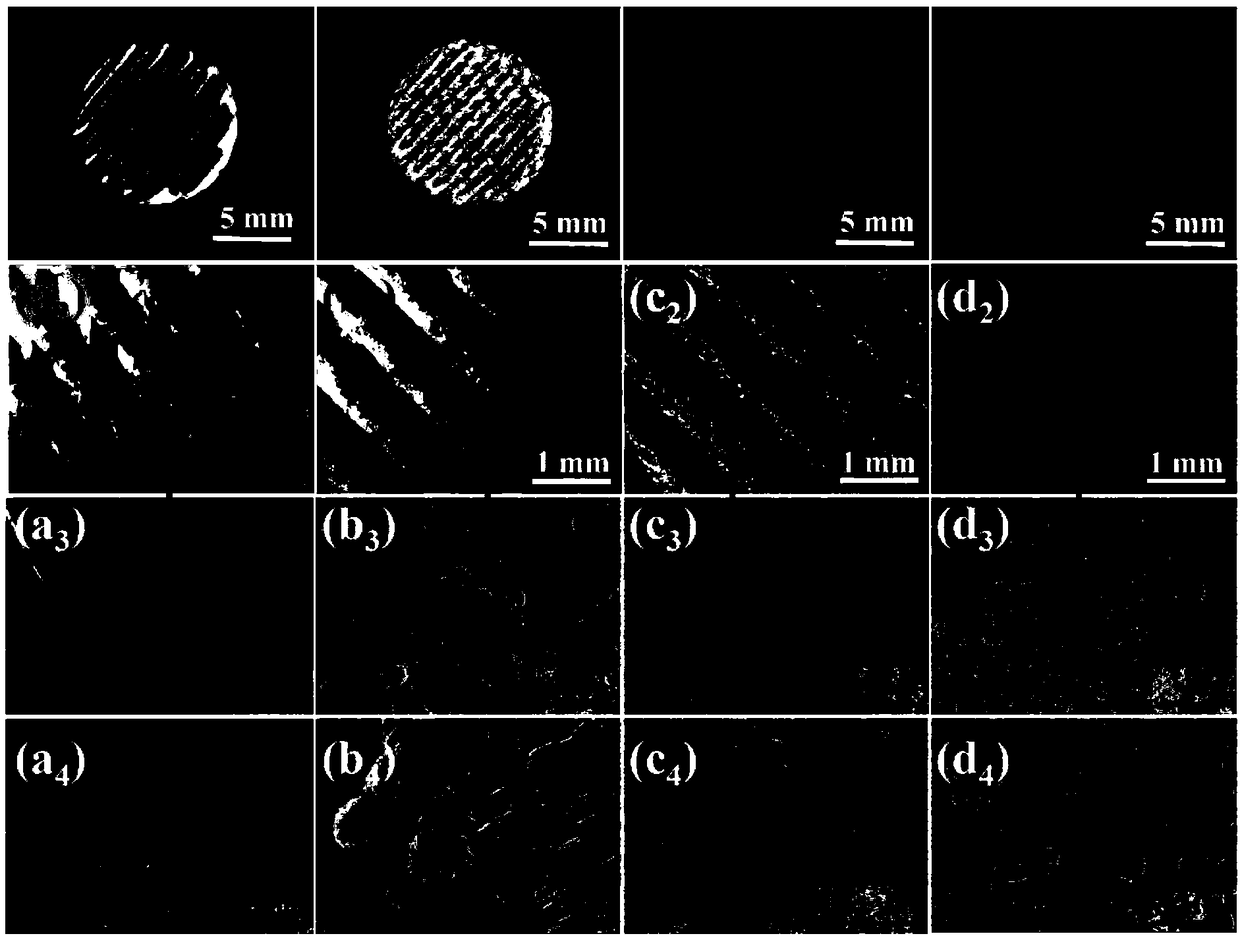

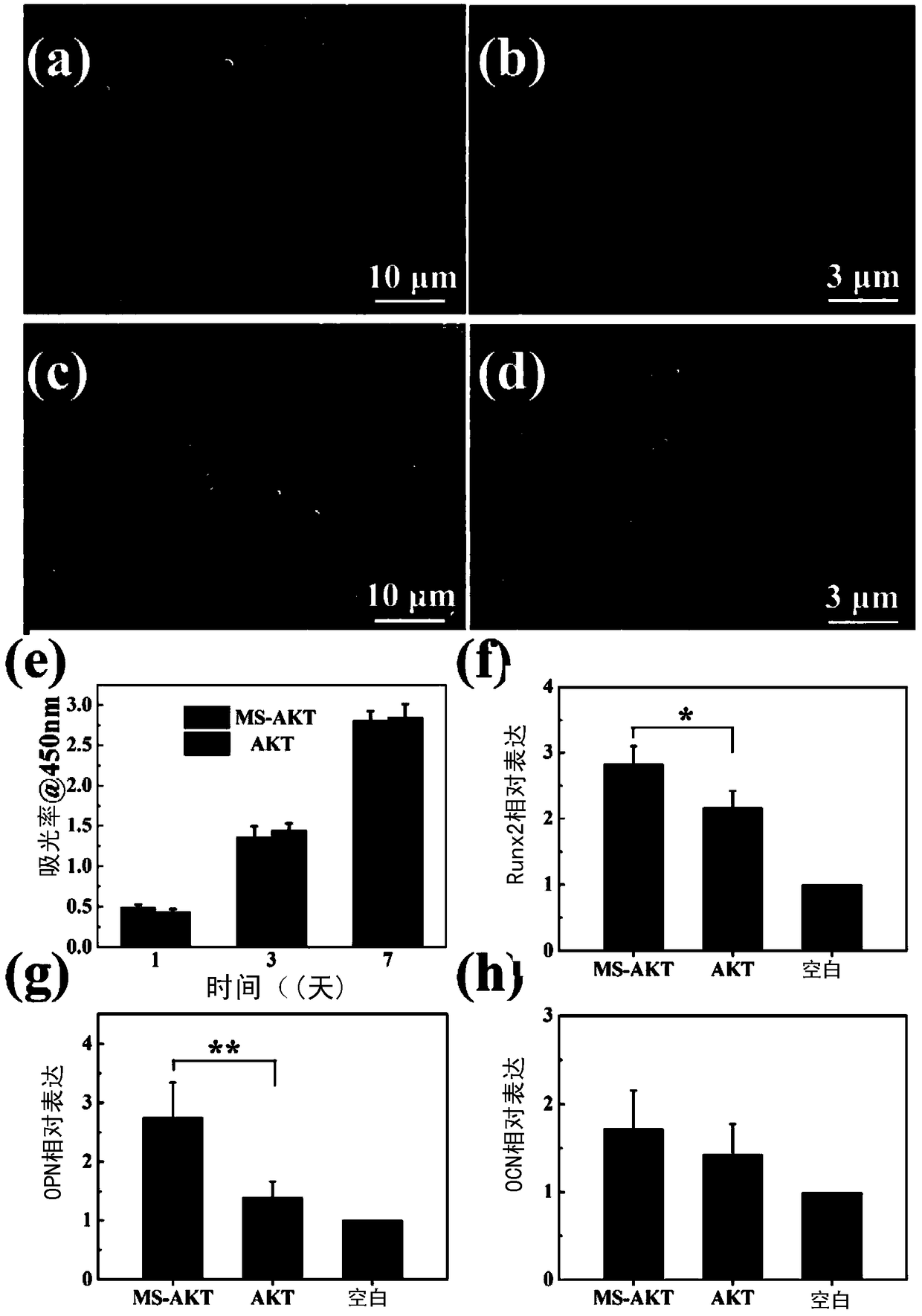

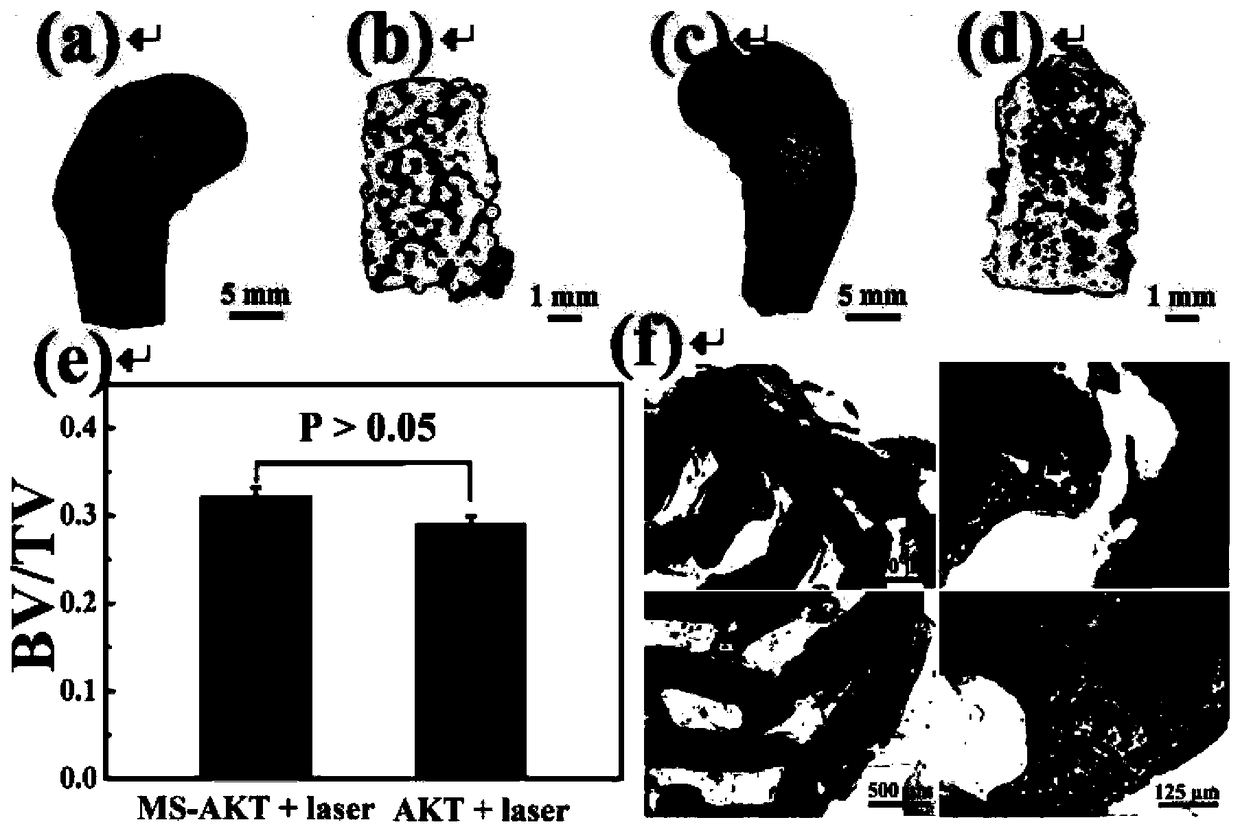

[0069] (1) After taking 5g of pure feldspar powder (Kunshan Huaqiao Technology New Material Co., Ltd.), 0.32g of sodium alginate powder and 2.5g of F127 aqueous solution with a mass fraction of 20%, the scaffold material was prepared by using three-dimensional printing technology;

[0070] (2) Calcinate the printed support at 1350°C for 3 hours to obtain a pure feldspar ceramic support AKT, the size of which is Ф11mmⅹ3mm;

[0071] (3) Add 1mmol ammonium molybdate tetrahydrate and 30mmol thiourea into 35mL deionized water to obtain a solution with a molar concentration of molybdenum atoms of 0.2mol / L. After stirring for 1 hour, pour it into the polytetrafluoroethylene 4g feldspar ceramic support. In the lining of the ethylene hydrothermal kettle, a black bracket was obtained after a 180°C hydrothermal reaction for 24 hours;

[0072] (4) After washing several times with ethanol and water, and drying in a vacuum oven at 60°C, a molybdenum disulfide-modified feldspar scaffold 0.2M...

Embodiment 2

[0086] (1) After fully mixing 5g of pure feldspar powder, 0.32g of sodium alginate powder and 2.5g of F127 aqueous solution with a mass fraction of 20%, the scaffold material was prepared by three-dimensional printing technology;

[0087] (2) Calcinate the printed support at 1350°C for 3 hours to obtain a pure feldspar ceramic support AKT, the size of which is Ф11mmⅹ3mm;

[0088] (3) Add 0.5mmol ammonium molybdate tetrahydrate and 15mmol thiourea into 35mL deionized water to obtain a solution with a molar concentration of molybdenum atoms of 0.1mol / L. After stirring for 1 hour, pour it into polytetrafluoroethylene with 4g feldspar ceramic support. In the lining of vinyl fluoride hydrothermal kettle, a black bracket was obtained after 180°C hydrothermal reaction for 24 hours;

[0089] (4) After washing several times with ethanol and water, and drying in a vacuum oven at 60°C, a molybdenum disulfide-modified feldspar scaffold 0.1MS-AKT was obtained;

[0090] (5) Place the stent...

Embodiment 3

[0094] (1) After fully mixing 5g of pure feldspar powder, 0.32g of sodium alginate powder and 2.5g of F127 aqueous solution with a mass fraction of 20%, the scaffold material was prepared by three-dimensional printing technology;

[0095] (2) Calcinate the printed support at 1350°C for 3 hours to obtain a pure feldspar ceramic support AKT, the size of which is Ф11mmⅹ3mm;

[0096] (3) 0.25mmol ammonium molybdate tetrahydrate and 7.5mmol thiourea were added into 35mL deionized water to obtain a molar concentration of molybdenum atom molar solution that was 0.05mol / L. After stirring for 1 hour, pour 4g feldspar ceramic support into the poly In the lining of tetrafluoroethylene hydrothermal kettle, a black bracket was obtained after hydrothermal reaction at 180°C for 24 hours;

[0097](4) After washing several times with ethanol and water, and drying in a vacuum oven at 60°C, a molybdenum disulfide-modified feldspar scaffold 0.05MS-AKT was obtained;

[0098] (5) Place the stent i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com