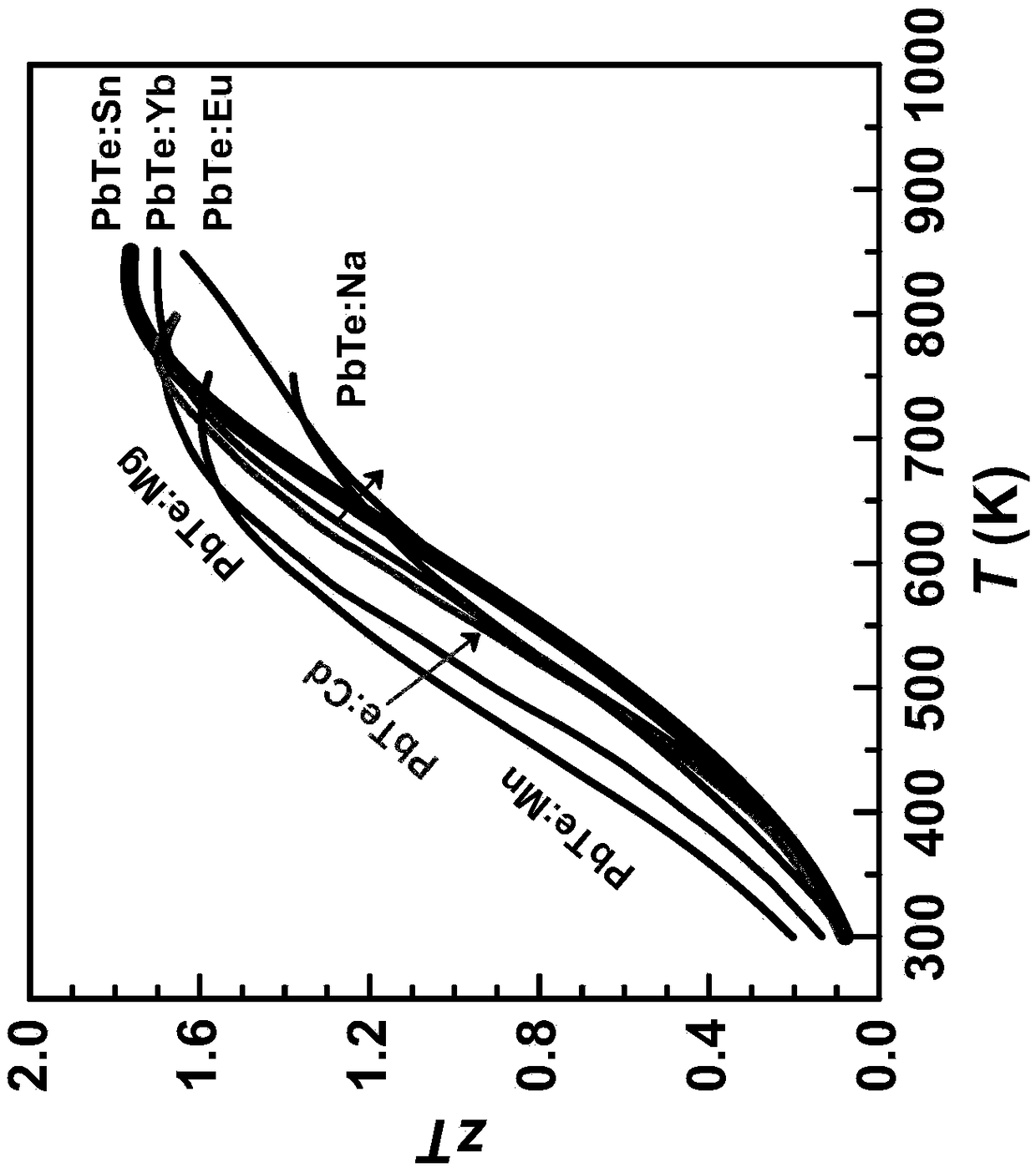

High-performance PbTe-SnTe alloy-based thermoelectric materials and preparation method thereof

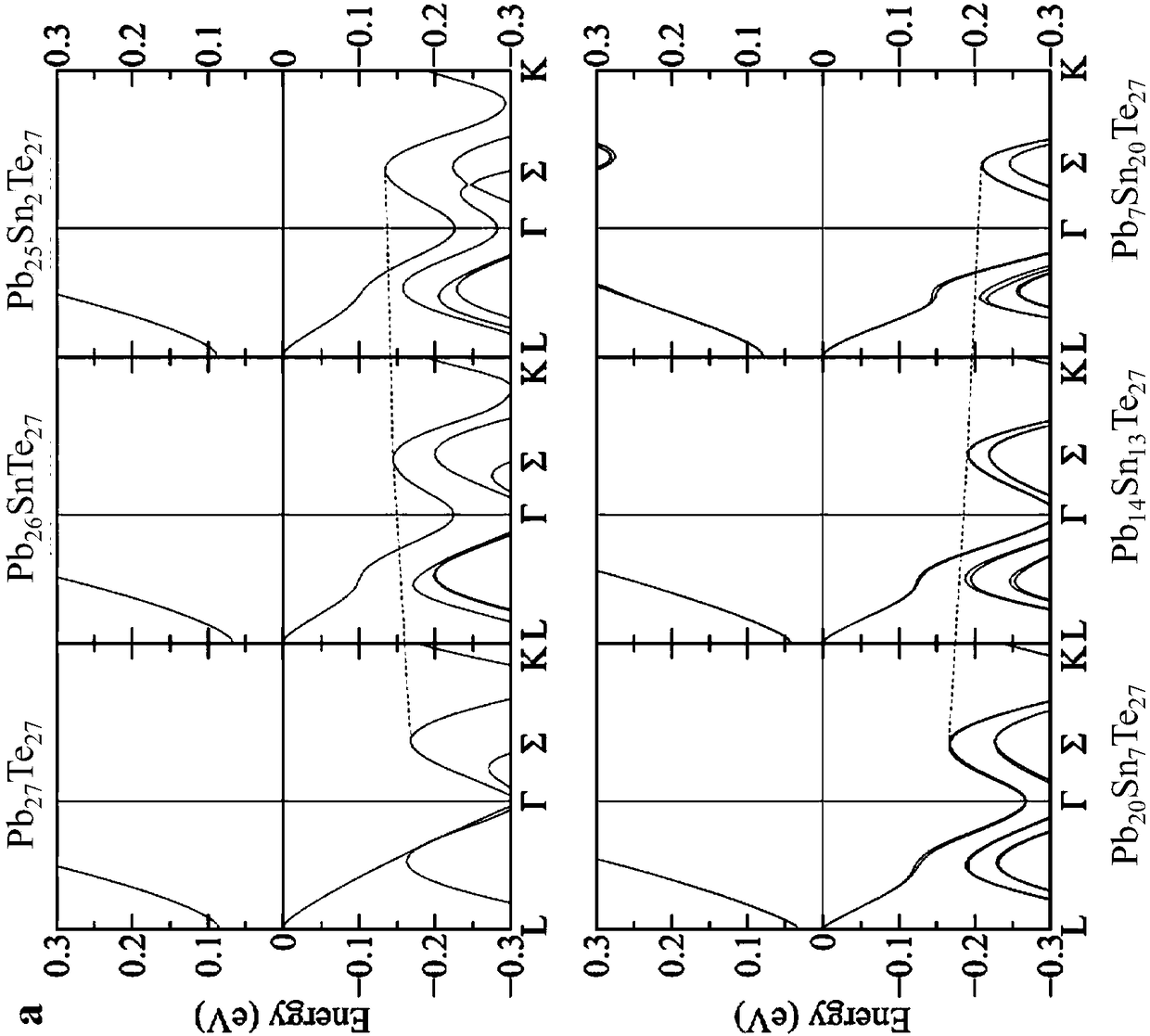

A technology based on thermoelectric materials and alloys, which is applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve problems such as difficult to meet thermoelectric materials, and achieve improved material degeneracy, high mechanical strength, and reduced The effect of a small energy difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In another embodiment of the present invention, a method for preparing a high-performance PbTe-SnTe alloy-based thermoelectric material comprises the following steps:

[0037] (1) Vacuum packaging: According to the stoichiometric ratio of 0.02:x:0.98-x:1, the elemental Na, Sn, Pb and Te are weighed as raw materials and mixed evenly, and then vacuum-packed in a quartz tube;

[0038] (2) Melting reaction quenching: heating the quartz tube to make the raw materials fully react in the molten state, and then quenching to obtain the first ingot;

[0039] (3) heat treatment and quenching: the first ingot is vacuum-packed in another quartz tube, quenched and cooled after heat treatment to obtain the second ingot;

[0040] (4) Pressurized sintering: Grinding the second ingot into powder, placing it in a graphite mold, sintering under vacuum and high temperature hot pressing, and then cooling to obtain a bulk material, which is the high-performance PbTe-SnTe alloy-based thermoelect...

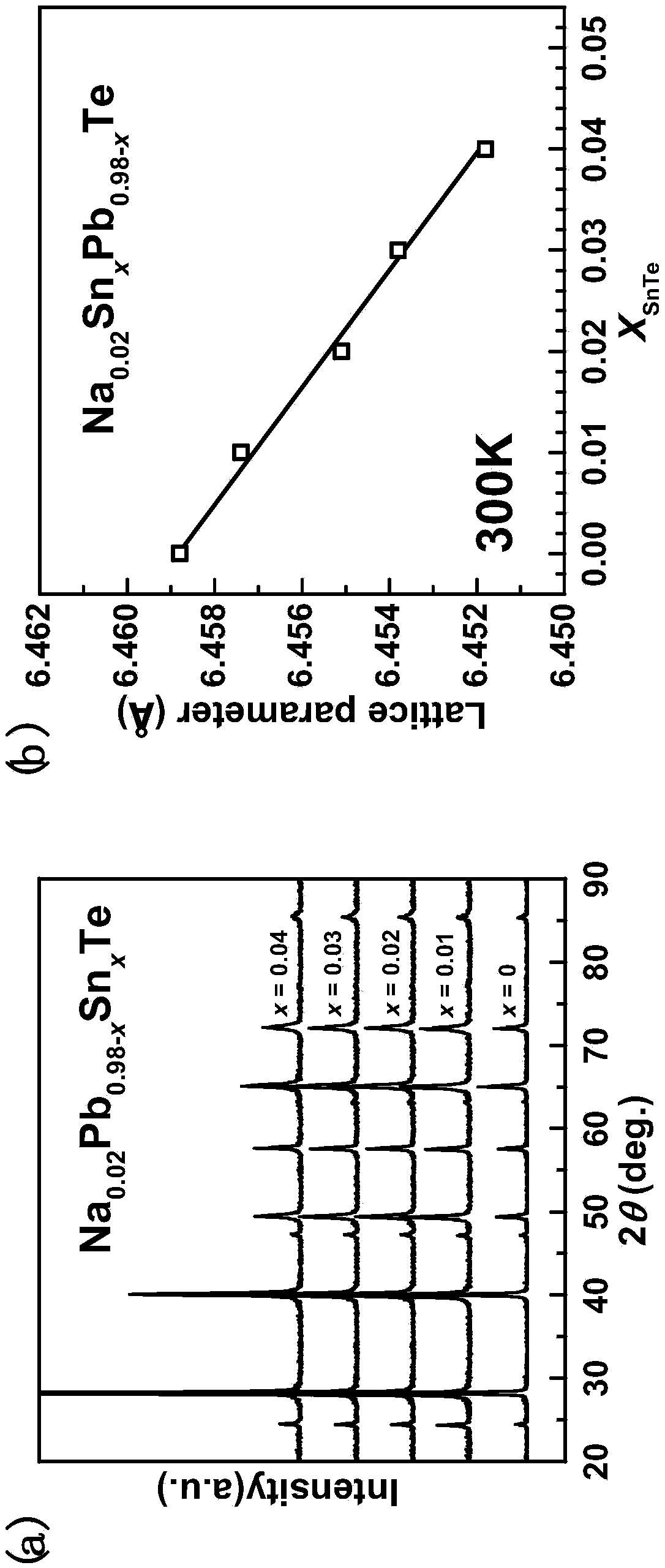

Embodiment 1

[0048] A high-performance PbTe-SnTe alloy-based thermoelectric material with the chemical formula Na 0.02 sn x Pb 0.98-x Te, where x=0-0.04. In the present embodiment, by getting x=0, 0.01, 0.02, 0.03, and 0.04 (when x=0, the chemical formula is Na 0.02 Pb 0.98 Te, x=0.01, 0.02, 0.03, 0.04 is energy band control and improves material degeneracy), according to the following preparation method, Na 0.02 sn x Pb 0.98-x Te bulk material:

[0049] (1) According to the value of different x, it becomes Na according to the composition 0.02 sn x Pb 0.98-x Stoichiometric ratio of Te (x=0-0.04) Weigh elemental raw materials sodium Na, tin Sn, lead Pb and tellurium Te with a purity greater than 99.9%, place the raw materials in a quartz tube, and seal the quartz tube under vacuum.

[0050] (2) Suspend the quartz tube containing the raw materials in a high-temperature muffle furnace, slowly raise the temperature to 1200-1400K at a rate of 150-300K / h, keep it warm for 6-10 hours, a...

Embodiment 2

[0061] Compared with Example 1, most of them are the same, except that in step (2) of the present example: the temperature is slowly raised to 1300K at a rate of 150K / h, and the temperature is kept at 1300K for 10h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com