High nickel-inorganic nano-powder composite electrode material and preparation method thereof

An inorganic nanomaterial and inorganic nanotechnology, applied in the field of energy storage materials and electrochemistry, can solve the problem that the cycle stability of high-nickel ternary cathode materials cannot meet the requirements of the service life of power batteries, and achieve good cycle stability, thickness Uniform and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]A preparation method of an electrode material composited with high nickel and inorganic nanopowder, comprising the steps of:

[0043] 1) LiNi 0.81 co 0.09 mn 0.10 (OH) 2 The precursor and LiOH·H2O were blended once in a high-speed mixer according to the mass ratio of 1:1.03, the blending speed was 600rpm, and the blending time was 20min;

[0044] 2) The product obtained in step 1) is sintered once in a high-temperature muffle furnace, the sintering temperature is 810°C, the pure oxygen flow rate is 35L / min, and the sintering time is 8 hours;

[0045] 3) Grinding the product obtained in step 2) with a mortar, and then sieving in a mechanical vibrating sieve to obtain a product with a size below 400 mesh;

[0046] 4) with step 3) gained product and ZrO 2 Secondary blending is carried out in a high-speed mixer, and the mass of ZrO2 accounts for 0.20% of the total mass of raw materials. , the blending speed is 500rpm, and the blending time is 25min;

[0047] 5) The pr...

experiment example 1

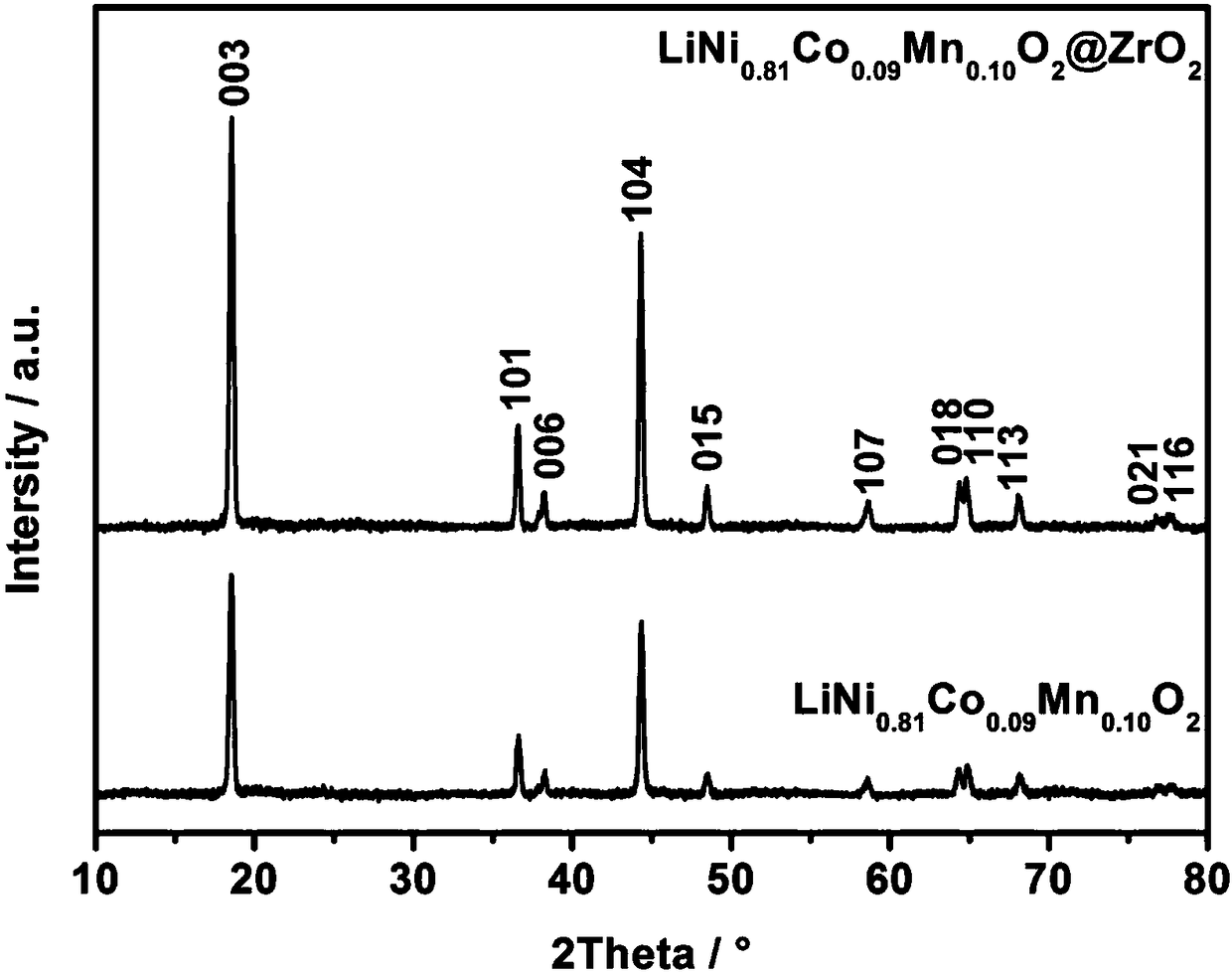

[0051] Take LiNi 0.81 co 0.09 mn 0.10 o 2 @ZrO 2 and LiNi 0.81 co 0.09 mn 0.10 o 2 As the experimental object, determined by X-ray diffractometer,

[0052] like figure 1 shows that LiNi 0.81 co 0.09 mn 0.10 o 2 @ZrO 2 with LiNi 0.81 co 0.09 mn 0.10 o 2 The peak positions are basically the same, indicating that ZrO 2 cladding layer on LiNi 0.81 co 0.09 mn 0.10 o 2 The crystal structure of the LiNi 0.81 co 0.09 mn 0.10 o 2 Has high crystallinity.

[0053] like figure 2 As shown, LiNi 0.81 co 0.09 mn 0.10 o 2 @ZrO 2 The diameter is about 10-15 μm.

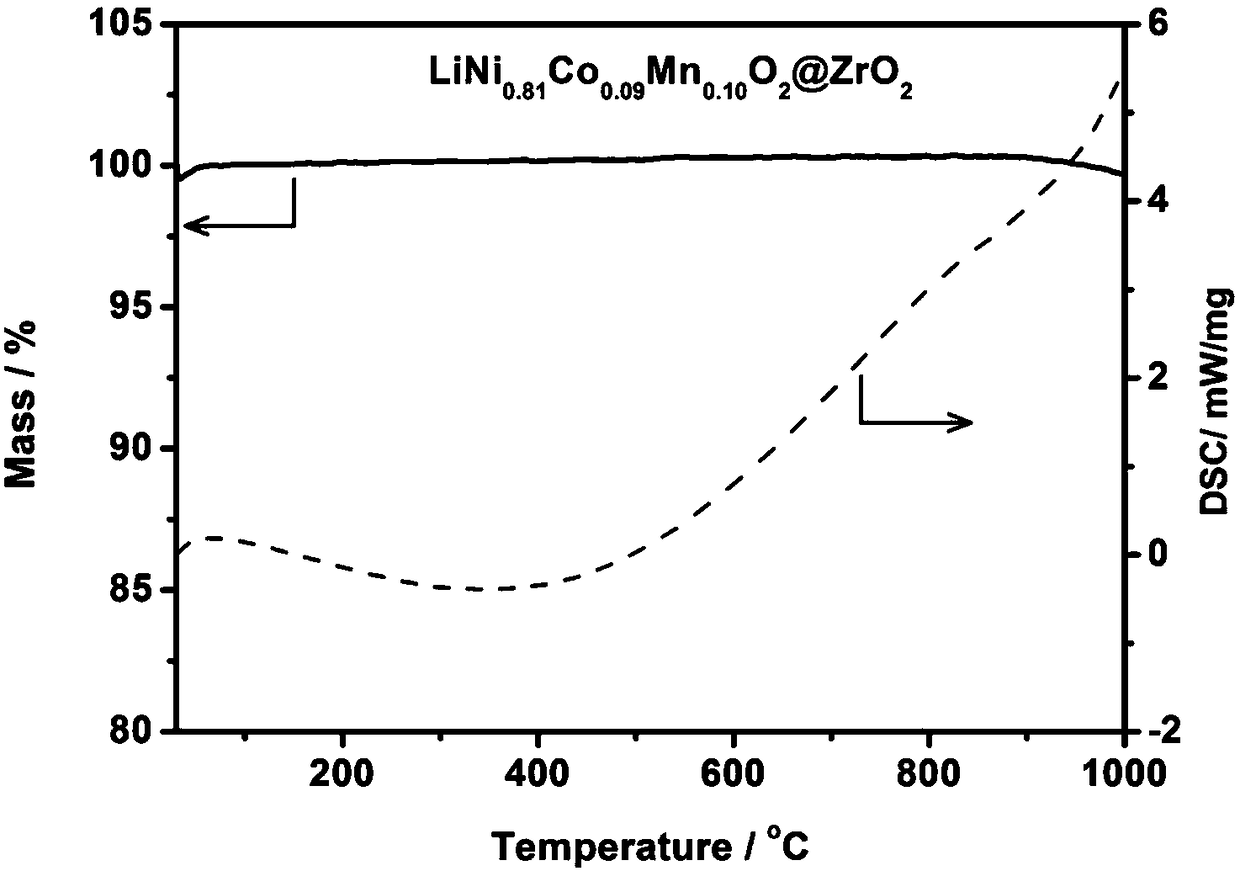

[0054] like image 3 As shown, LiNi 0.81 co 0.09 mn 0.10 o 2 @ZrO 2 Has high thermal stability.

[0055] like Figure 4 for LiNi 0.81 co 0.09 mn 0.10 o 2 @ZrO 2 FT-IR test results.

[0056] like Figure 5 for LiNi 0.81 co 0.09 mn 0.10 o 2 @ZrO 2 The Raman map.

[0057] like Image 6 As shown, LiNi 0.81 co 0.09 mn 0.10 o 2 @ZrO 2 The five elements of Ni, Co, Mn, O and Zr are ...

Embodiment 2

[0065] 1) LiNi 0.81 co 0.09 mn 0.10 (OH) 2 The precursor and LiOH·H2O were blended once in a high-speed mixer according to the mass ratio of 1:1.04, the blending speed was 650rpm, and the blending time was 25min;

[0066] 2) The product obtained in step 1) is sintered once in a high-temperature muffle furnace, the sintering temperature is 830°C, the pure oxygen flow rate is 40L / min, and the sintering time is 10 hours;

[0067] 3) Grinding the product obtained in step 2) with a mortar, and then sieving in a mechanical vibrating sieve to obtain a product with a size below 400 mesh;

[0068] 4) with step 3) gained product and TiO 2 Secondary blending in high speed mixer, TiO 2 The quality accounts for 0.25% of the total mass of raw materials, the blending speed is 1500rpm, and the blending time is 20min;

[0069] 5) The product obtained in step 4) is subjected to secondary sintering, the sintering temperature is 620°C, the flow rate of pure oxygen is 15L / min, and the sinter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com